Through grinding and polishing, and observing under optical microscope, it is found that the middle part of the crack is relatively wide, the two ends are narrow, and the cracks are distributed in a curved discontinuous curve. There is a big difference between the width and narrow transition between the middle part and the two ends, and there is no obvious transition form. No inclusions are found in the crack, and a small amount of gray non-metallic inclusions are found near both ends of the crack, as shown in Fig. 7.

After corrosion, no decarburization was found on both sides of the crack. The morphology of cracks and inclusions after corrosion is shown in Fig. 8.

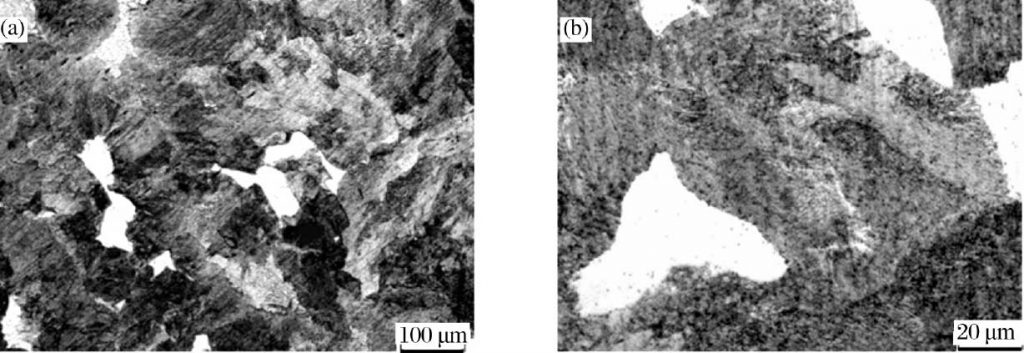

Under the optical microscope, the microstructure of the sample is lamellar pearlite + a small amount of massive ferrite, which is the normal structure after forging. The specific structure is shown in Fig. 9.