I. Introduction

Helical cylindrical gears are widely used in various mechanical equipment due to their high transmission efficiency, smooth transmission, strong transmission capacity, and low noise. They play an important role in agricultural machinery, such as tractors, harvesters, planters, and mixers. The X62W milling machine has the advantages of high precision, high efficiency, controllable accuracy, wide processing range, and cost reduction in processing helical cylindrical gears, making it widely used, especially in the field of agricultural machinery processing.

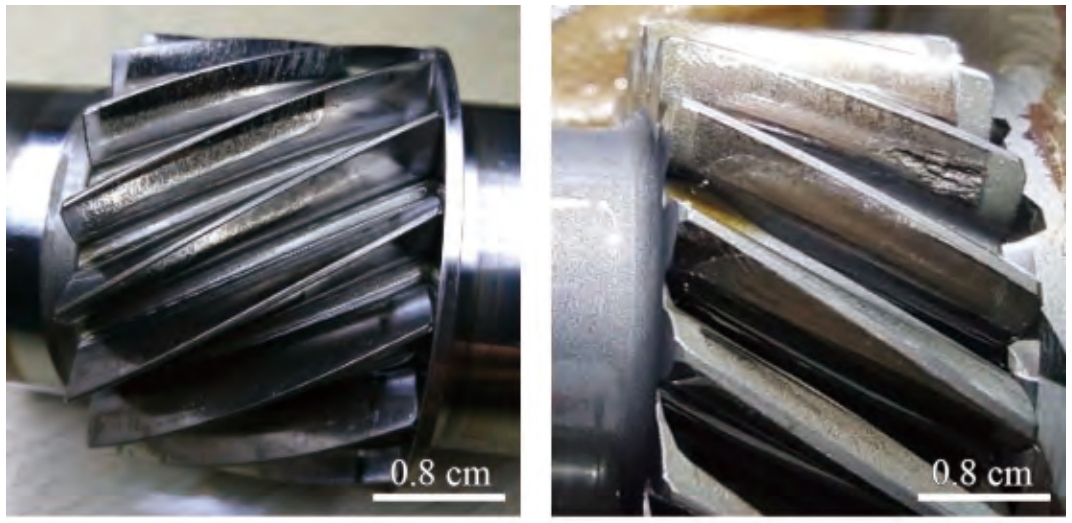

II. Basic Information of the Helical Cylindrical Gear to Be Processed

The parameters of the helical cylindrical gear in this article are as follows: tooth number , normal modulus , tooth profile angle , helix angle , left-handed, accuracy grade , and the material is 45.

III. Milling Process of the Helical Cylindrical Gear with X62W Milling Machine

A. Fine Adjustment

There are 13 precision grades for gears, ranging from 0 to 12 in ascending order, with 0 being the highest and 12 the lowest. The gear in this article has a 9th-level precision, which belongs to the low-precision level. The common processing methods for such involute gears are the generating method and the profiling method. Since the required precision of this gear is not high, the profiling method is adopted with the X62W milling machine.

B. Selection of Gear Milling Cutter and Cutting Fluid

- Selection of milling cutter: The gear should be selected according to the normal modulus , the normal tooth profile angle (), and the equivalent tooth number to determine the cutter number. The intersection of the normal plane at a certain point on the tooth line of the helical gear with the indexing cylinder surface is an ellipse. Take the maximum curvature radius of this ellipse as the pitch circle radius of an imaginary spur gear, and take the normal tooth profile angle of the helical gear as the modulus and tooth profile angle of this imaginary spur gear, then this imaginary spur gear is the equivalent gear of this helical gear. Through the formula or , the equivalent tooth number is obtained as . Then, by looking up the standard disc gear milling cutter number table based on the equivalent tooth number, when the tooth number is 21 to 25, an 8-piece set of No. 4 standard disc gear milling cutter with a modulus should be selected.

- Selection of cutting fluid: The main role of the cutting fluid in the milling gear processing is cooling, and it also has a certain flushing ability. Due to the older model of the X62W milling machine, to avoid rusting of the internal gears, the oil lubrication method is preferred. Among various cutting oils, considering cost savings and safety issues, No. 0 diesel is selected instead of kerosene as the cutting fluid.

C. Preparatory Work Before Milling Teeth

- Calibration of the milling machine: According to the given rotation direction of the parameters, determine the rotation direction of the workbench. For left-handed rotation, rotate the workbench clockwise by the corresponding angle; for right-handed rotation, rotate it counterclockwise by the corresponding angle. In this example, since the parameters are left-handed, the milling machine workbench is rotated clockwise by 9°.

- Installation of the indexing head and tailstock: When installing, ensure that the distance between the two is appropriate to ensure sufficient space for workpiece clamping and disassembly.

- Preparation of the mandrel: Select a suitable mandrel according to the inner hole of the gear blank to ensure that the gear blank can be firmly clamped without affecting the milling process.

- Inspection, installation, and correction of the gear blank: Mainly check the outer circle and inner hole sizes, the coaxiality of the outer circle and inner hole, and the runout of the tooth end face to the inner hole axis. Fix the inspected gear blank on the mandrel, and install the mandrel together with the gear blank between the main shaft of the indexing head and the tailstock center. Rotate the indexing handle and use a dial indicator to check whether the coaxiality of the outer circle of the gear blank meets the requirements.

- Installation of the milling cutter and centering by the marking test cut method: Mount the milling cutter and use the marking test cut method to ensure that the axis of the milling cutter is aligned with the center of the gear blank.

D. Processing-related Calculations and Installation of the Exchange Gears

- Lead calculation: The lead is actually the milling distance of the cutter on the workpiece, and the sine value of the helix angle is the ratio of the lead to the semi-circumference. The calculation of the exchange gears is actually to calculate the speed ratio, that is, the ratio of the distance of the cutter’s milling path when the indexing head rotates 360° to the movement distance of the workbench. In other words, the goal of calculating the hanging gears is to ensure that when the workbench drives the indexing head to rotate 360°, the cutter just completes 360° on the normal projection of the workpiece. The calculated lead is approximately 1508.

- Exchange gear calculation: The lead screw pitch of the workbench longitudinal drive of the X62W milling machine is mm. Through calculation, the speed ratio is approximately 0.2268. By adjusting the tooth numbers of the exchange gears , , , and , the actual exchange gears are determined as , , , and .

- Installation of the exchange gears: Adopt the side shaft hanging gear method to connect the workbench longitudinal lead screw with the side shaft of the indexing head. Because the rotation direction of the gear to be processed is left-handed, an intermediate gear should be selected to adjust the rotation direction of the gear blank. During the installation process, first, loosen the indexing plate fastening screws, then install the driven gear on the side shaft at the rear end of the main shaft of the indexing head, and install the driving gear at the tail of the workbench longitudinal lead screw. Connect and together with a key and install them between and . Use the transition gear to indirectly engage by . The and are coaxially driven, and is driven by , that is, and are the driving gears, and and are the driven gears. When making the final connection, pay attention to the appropriate clearance of each pair of gears. According to the actual installation situation, the final selection of the intermediate transition gear is made. The tooth number of the intermediate transition gear does not affect the lead calculation, and only a gear with a suitable tooth number needs to be selected to ensure a smooth and stable transmission process.

- Indexing calculation: Calculate the indexing number as . Among the commonly used hole disks, select a hole ring that contains a multiple of 21. In the case of multiple choices, select a hole ring with as many holes as possible to maximize the processing accuracy. Therefore, the final hole ring is selected as 42 holes. Then, . Adjust the indexing fork according to 38 hole spacings (39 holes).

E. Milling of the Gear

- Inspection: Before starting milling, check whether the rotation direction of the main shaft of the indexing head is correct and whether the lead is error-free. Only when both are correct can milling begin.

- Selection of milling method: Generally, the analysis and comparison should be carried out from the following aspects to select different milling methods.

- From the aspect of the change in the cutting thickness: During reverse milling, the cutting thickness on each tooth changes from zero to the maximum. Due to the cutting edge of the tooth not being able to be ground absolutely sharp, the cutting edge cannot immediately cut into the workpiece at the beginning but squeezes and rubs the surface to be processed, and then cuts into the workpiece after sliding a certain distance. This will cause the work surface to harden, affecting the surface quality, and at the same time accelerating the wear of the tooth face. When milling in the forward direction, the cutting thickness of the tooth changes from the maximum to zero, so a better surface quality can be obtained, and the durability of the tool is also improved.

- From the aspect of the force on the workpiece: When milling in the forward direction, the feed thrust causes the threads of the lead screw and nut to be compressed tightly on one side, while a gap appears on the other side. At this time, the component force of the tooth of the milling cutter acting on the workpiece is transmitted to the workbench, causing the workbench to be under tension. When the tension is large, the close contact surface between the lead screw and nut will suddenly shift to the side with the gap, that is, the workbench will move due to tension, causing the milling cutter to be damaged due to chipping, and the workpiece may also be scrapped.

- From the aspect of the component force of the milling cutter on the workpiece: When milling in the forward direction, the component force of the milling cutter’s tooth on the workpiece is vertically downward, which is beneficial for clamping the workpiece. While during reverse milling, the cutting component force is opposite to the feed direction, and there will be no phenomenon of workbench movement, but the cutting component force is vertically upward, and the workpiece is subject to the upward pull of the milling cutter, which is not conducive to the clamping of the workpiece, and is likely to cause deformation and vibration of the workpiece, making the cutting not smooth, and even leading to workpiece damage.

Therefore, forward milling is beneficial for improving the durability of the milling cutter and the stability of the workpiece clamping, which is beneficial for improving the processing quality, but it can only be used for milling machines with a small gap that can be adjusted and for workpieces without hard skins. In this processing of helical cylindrical gears, the X62W milling machine is used, and the lead screw used in this model is a nut lead screw, which has lower accuracy compared to the ball screw on a CNC machine, a large gear gap in the machine, relatively poor rigidity, and not very good coordination. During the processing, reverse milling is better for rough machining, while forward milling is better for finish machining.

- Selection of the rotational speed of the milling cutter: According to the milling speed table for spur cylindrical gears, it is found that for the 45 steel material, the milling speed is approximately 32 m/min during rough milling, and approximately 40 m/min during finish milling. The spindle rotational speed of the milling machine can be calculated based on the formula , where is the diameter of the milling cutter. The diameter of the gear disc cutter used is approximately 70 mm. Through formula calculation, the spindle rotational speed is selected as rpm during rough milling and rpm during finish milling.

- Rough milling of the gear tooth profile: The milling width during rough milling is calculated and selected as mm. Due to the relatively low depth, the workbench can be raised by 49.5 mm at one time and milled tooth by tooth.

- Finish milling of the gear: According to the equivalent tooth number , look up the table for interpolation calculation to obtain and . Calculate the circular tooth thickness of the pitch circle as and the circular tooth height of the pitch circle as . Use a tooth thickness vernier caliper to measure the circular tooth thickness of the pitch circle and record the measurement data. Calculate the additional feed amount during finish milling based on , where is the actual measured value of the circular tooth thickness of the pitch circle after rough milling. Feed the cutter by the value for milling processing to complete the final finish milling.

IV. Notes

- Before milling, it is necessary to conduct a test cut to check whether the hanging gears, lead, and workbench rotation direction are adjusted correctly.

- Before milling, loosen the locking handle of the main shaft of the indexing head and also loosen the fastening screws of the indexing plate.

- During the milling process, the pin of the indexing handle must be inserted into the corresponding hole on the indexing plate.

- When clamping the workpiece, select the nut according to the rotation direction. For this workpiece with left-handed rotation, select a left-handed nut. For better fastening effect, a fine-pitch left-handed nut should be used to fix the workpiece.

- Because there is a certain gap in the nut lead screw feed system, when the workpiece is returned with the workbench after one tooth is milled, it must be lowered to a certain height to prevent the already processed tooth grooves from being scratched.

V. Possible Problem Analysis

A. Incorrect Tooth Number Compared to the Given Drawing

The possible reasons are as follows:

- Errors in the indexing calculation.

- Incorrect selection of the indexing plate hole ring.

- Incorrect adjustment of the hole spacing number between the indexing forks.

B. Excessive Tooth Pitch Deviation and Unequal Tooth Thickness

The possible reasons are:

- Failure to conduct radial runout detection on the workpiece, resulting in excessive radial runout of the workpiece.

- Deviation in indexing, where the indexing handle is rocked in both directions during indexing, causing excessive clearance in the worm gear transmission mechanism inside the indexing head.

C. Teeth Tilting to One Side

The possible reason is that the milling cutter axis did not align with the center of the gear blank before starting processing, resulting in excessive centering error.

D. Excessive Tooth Height or Tooth Thickness Size Deviation

The possible reasons are:

- Errors in the selection of the milling cutter modulus or cutter number before milling.

- Incorrect calculation of the milling depth or feed error.

E. Poor Tooth Surface Roughness

The possible reasons are:

- Considerable vibration generated during milling.

- Incorrect adjustment of the milling parameters.

- Tool wear or non-standard installation.

VI. Conclusion

Processing helical cylindrical gears with the X62W milling machine requires a series of precise operations and calculations. From the selection of the milling cutter and cutting fluid to the various preparations before milling, as well as the processing-related calculations and the actual milling process, each step needs to be carried out carefully to ensure the quality and accuracy of the gear. At the same time, attention should be paid to possible problems that may occur during the processing and take corresponding measures to avoid or solve them. By following the correct processing methods and precautions, high-quality helical cylindrical gears can be obtained, meeting the requirements of different applications.