Generally, during the operation of the automotive electronic control system, the ECU will calculate and judge the physical parameters and working status of the controlled components according to the data flow input by the sensor, and then send the control data flow to the actuator. The actuator works under the action of these data flows to control the controlled object within the set target range. Under this premise, the calculation of the elastic deformation modification of electric vehicle cylindrical gear becomes an important link. The calculation of this data mainly depends on the actual deformation of electric vehicle cylindrical gear meshing and the production error. At the current stage, all major automobile manufacturers will use a set of self-developed shape modification scheme, and continue to accumulate experience in the daily maintenance process.

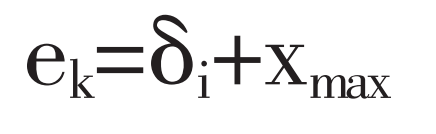

Formulate practice quantity parameters. Generally, the maximum modification amount of electric vehicle cylindrical gear components appears at the top and root of electric vehicle cylindrical gear, and the calculation formula is:

δ i: The maximum geometric interference at the meshing position of electric vehicle cylindrical gears caused by production errors;

Xmax: the maximum comprehensive deformation generated by the meshing of a pair of electric vehicle involute cylindrical gears.

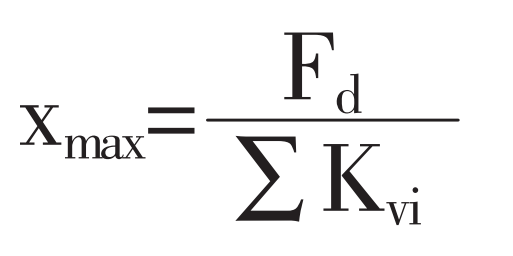

In the formula:

FD: normal biting force of cylindrical gear of electric vehicle;

∑ kvi: the comprehensive stiffness generated by meshing the cylindrical gear of electric vehicle to the total meshing.

According to the formula, FD is fixed, and the smaller Σ kvi is, the larger xmax is. Σ K reaches the minimum value when the cylindrical gear of electric vehicle passes through the inlet and outlet points in the meshing process. If the coincidence is less than 2, then:

Kv1: comprehensive stiffness value of electric vehicle cylindrical gear at 1 point of meshing position;

Kv2: comprehensive stiffness value of cylindrical gear of electric vehicle at 2 points of meshing position.

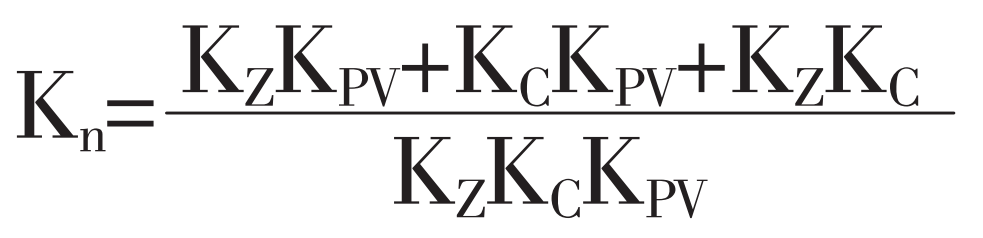

The formula can be calculated as follows:

KZ: stiffness value of driving gear at meshing point I;

Kc: stiffness value of the driven gear at the meshing point I;

Kpv: stiffness value when contact deformation effect occurs.

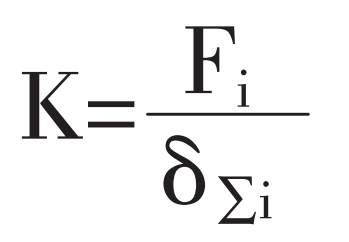

When n=1, 2, KZ, KC, kpv are calculated according to the formula:

Fi: normal meshing force at the meshing position of point I;

δ Σ I: the sum of the overall deformation in the direction of the meshing line at the meshing position.