There are many methods of gear profile modification. According to the accuracy requirements of gear and gear batch, choosing the appropriate modification method is of great benefit to improve labor productivity, ensure product quality and reduce cost.

Tooth profile modification can be divided into hot front modification and hot rear modification. Hot front modification mainly includes hobbing modification and shaving modification. Hot rear modification mainly includes grinding modification and electrochemical modification.

In order to modify the tooth profile, the shape of the modification must be determined first, and the effect of the modification must be confirmed.

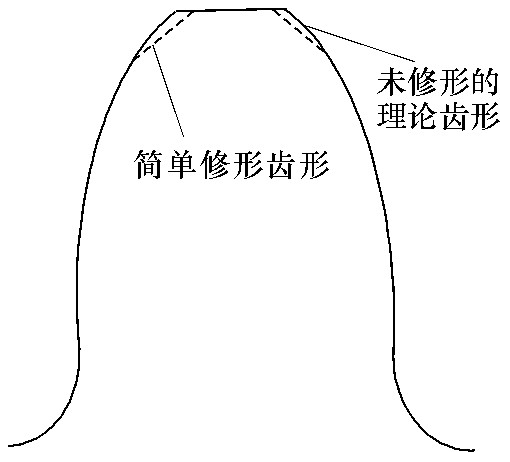

1. Simple shaping

The simple modification is to lower the top of the tooth profile, that is, to trim the edge. As shown in Figure 1, the solid line is the theoretical involute tooth profile, and the dotted line is the trimming tooth profile. The main purpose of trimming is to reduce the noise. The trimming height is generally about 0.5mm, and the angle (hob tooth angle) can be selected from 30 ° ~ 75 ° according to the situation. Generally, the processing method of trimming is gear hobbing. The edge of ordinary hob is a section of oblique line, and the edge of trimming hob is two sections of oblique line (as shown in Figure 2). One section near the root of hob is used to process the tooth top trimming edge. According to the principle of gear hobbing, the top of gear is modified

Part of it is not an oblique line, but an involute with an increased pressure angle.

If the accuracy requirement is not high, you can also use pneumatic or electric tools to make simple shape modification by hand.

2. Precise shaping

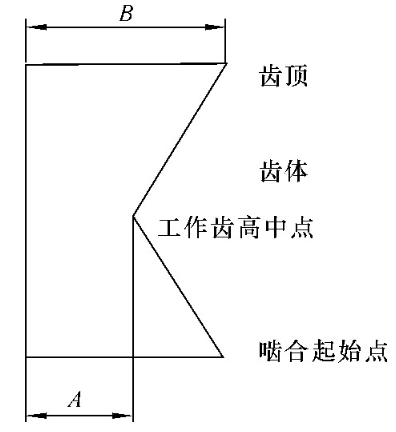

For shape modification, the shape to be repaired must be made first, that is, the K-shape block diagram must be made first. There are many shapes of K-shaped block diagram. In JB / T 5615-2004 technical conditions for transmission gears of tractors, “tooth profile modification is recommended, and the tooth profile detection line of the working face of the modified gear shall be within the range of Fig. 3 (K-shaped block diagram)” [2]. We can determine the K-shaped block diagram of tooth profile modification according to this regulation, and then modify it according to the test or use situation.

According to this, the number of teeth of a planetary gear z = 21, modulus M = 4, pressure angle α = 20 °, and the accuracy grade of tooth shape error shall be grade 7 according to the requirements of GB / T 10095.1. According to these parameters, the tooth tolerance of national standard is 0.01 for level 6, 0.015 for level 7 and 0.021 for level 8. Then a = 0.01 and B = 0.021 in Figure 3.

A increases the value by one level according to the gear accuracy level B decreases the value by one level according to the gear accuracy level