1. Introduction

Permanent magnet gears have gained significant attention in recent years due to their unique advantages such as contact – less transmission, high torque density, and high efficiency. Among various types of permanent magnet gears, the multi – shaft ring – plate permanent magnet gear (MRMG) is a novel structure that shows great potential in different applications. This article aims to provide a detailed and comprehensive analysis of the MRMG, covering its structure, operating mechanism, magnetic field and torque calculation, performance evaluation through finite – element analysis and experiments, and finally, its conclusions and prospects.

1.1 Background of Permanent Magnet Gears

Permanent magnet gears achieve the conversion of mechanical energy between input and output shafts with transmission ratio characteristics by coupling the air – gap magnetic fields among teeth through the alternately distributed permanent – magnet poles on the surface. Compared with traditional mechanical gears, they can avoid problems like tooth surface wear, pitting, and tooth root fracture caused by contact – type transmission [1 – 5]. Currently, the main types of permanent magnet gears are concentric – type and cycloid – type.

The concentric – type permanent magnet gear (CPMG), represented by the magnetic – field – modulated gear, has advantages such as high torque density and high transmission efficiency [6 – 8]. However, its magnetic – modulation device is complex, and it consists of three – layer rotors and two – layer air – gaps, which makes the prototype manufacturing difficult [9, 10].

The cycloid – type permanent magnet gear (CMG) forms an eccentric air – gap magnetic field using inner and outer permanent – magnet rings and outputs the required motion through a specific output mechanism. It has a high torque density and a large transmission ratio because its effective coupling area accounts for more than 2/3 of the total magnetic – ring area and its motion principle is the same as that of the mechanical few – tooth – difference gear [11, 12]. But its major drawback is that the arm – bearing is located inside the cycloid gear, resulting in a small center – distance between the arm – bearing and the output shaft. Coupled with the radial load generated by the eccentric magnetic field, the total load on the arm – bearing is too large, seriously reducing the reliability and service life of the CMG [13 – 15].

1.2 The Emergence of MRMG

To address the problems of existing permanent – magnet gears, the MRMG structure is proposed based on the mechanical ring – plate gear structure and its operating principle. The MRMG is mainly composed of inner and outer permanent – magnet rings. The outer permanent – magnet ring (referred to as the ring – plate) is equipped with multiple eccentric shafts that can limit its self – rotation, restricting it to only perform a revolution – pendulum motion around the center and forcing the inner permanent – magnet ring to perform a fixed – axis self – rotation motion.

The MRMG has the same high torque density and large transmission ratio as the CMG because their effective coupling areas are the same. However, the eccentric shafts and their attached arm – bearings of the MRMG are located outside the center of the ring – plate. This allows for the distribution of the uneven electromagnetic forces formed by the eccentric magnetic field between the inner and outer permanent – magnet rings by increasing the number of eccentric shafts and arm – bearings, effectively solving the key technical problems of low arm – bearing life and poor operation reliability in the CMG.

2. Structure and Operating Mechanism of MRMG

2.1 Structure of MRMG

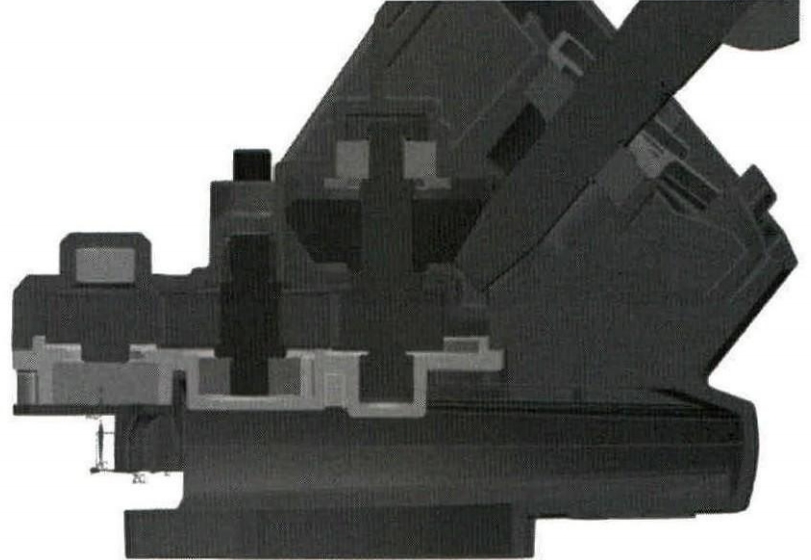

As shown in Figure 1, the MRMG consists of inner and outer permanent – magnet rings, a central shaft, and () eccentric shafts. The inner permanent – magnet ring is composed of an inner permanent magnet, a yoke, and a central shaft. The center of the central shaft is point , the inner and outer radii of the inner permanent magnet are and respectively, and the inner radius of the inner yoke is . The outer permanent – magnet ring is composed of an outer permanent magnet, a yoke, and eccentric shafts. Its center is point , the inner and outer radii of the outer permanent magnet are and respectively, and the outer radius of the outer yoke is . The eccentricity between the inner and outer permanent – magnet rings is , and the magnetic – deflection angle formed by the centerlines of the inner and outer permanent magnets at the minimum air – gap is .

| Component | Symbol | Description |

|---|---|---|

| Inner permanent – magnet ring | – | Composed of inner permanent magnet, yoke, and central shaft. Center of central shaft: , Inner radius of inner permanent magnet: , Outer radius of inner permanent magnet: , Inner radius of inner yoke: |

| Outer permanent – magnet ring | – | Composed of outer permanent magnet, yoke, and eccentric shafts. Center: , Inner radius of outer permanent magnet: , Outer radius of outer permanent magnet: , Outer radius of outer yoke: |

| Eccentricity | Distance between the centers of the inner and outer permanent – magnet rings | |

| Magnetic – deflection angle | Angle formed by the centerlines of the inner and outer permanent magnets at the minimum air – gap |

The eccentric shafts on the yoke of the outer permanent – magnet ring are evenly distributed along the circumferential direction with the same eccentricity, and the distances from their respective rotation centers to the central shaft of the inner permanent – magnet ring are equal. The rotation radius of the eccentric shaft is the eccentricity, which is much smaller than the outer diameter of the permanent magnet of the inner permanent – magnet ring.

2.2 Operating Mechanism

When the inner permanent – magnet ring is the input end and the eccentric shafts are the output ends, the MRMG can achieve a large – transmission – ratio speed – increasing motion. Conversely, when the eccentric shafts are the input ends and the inner permanent – magnet ring is the output end, it can achieve a large – transmission – ratio speed – reducing motion. Since the magnetic – field and torque calculation methods for both transmission methods are the same, this article only studies the speed – increasing mode.

Let the number of pole – pairs of the inner and outer permanent – magnet rings be and respectively, the self – rotation angular velocity of the inner permanent – magnet ring be , and the revolution angular velocity of the outer permanent – magnet ring be . Because the alternating frequency of the eccentric magnetic field corresponding to each self – rotation of the inner permanent – magnet ring is , and the alternating frequency corresponding to each revolution of the outer permanent – magnet ring is , the magnetic – deflection angle can be expressed as.

When the inner permanent – magnet ring starts to rotate from the static equilibrium position around the center point , due to the speed difference between the inner and outer permanent – magnet rings, the permanent magnets of the outer permanent – magnet ring cannot rotate to the equilibrium position aligned with those of the inner permanent – magnet ring, resulting in a magnetic – deflection angle and an electromagnetic torque greater than the load. This makes the angular acceleration of the outer permanent – magnet ring, causing it to perform a planar acceleration swing around the center point of the inner permanent – magnet ring. The arm – bearings enable the eccentric shafts evenly distributed on the yoke of the outer permanent – magnet ring to achieve a fixed – axis rotation that is the same as the revolution of the outer permanent – magnet ring.

When the speeds of the outer permanent – magnet ring and the eccentric shafts gradually reach the synchronous speed of the eccentric magnetic field, and both approach 0, while and approach fixed values. At this time, the MRMG is in a stable operation state, and the speed ratio and torque ratio can be expressed.