1. Introduction

1.1 Background and Significance

In the era of rapid technological advancement, the development of defense, robotics, and aerospace industries has propelled the demand for high-precision machine tools. Cycloid gear forming grinding machines play a crucial role in the production of precision reducers for industrial robots, with the machine column being a key component directly influencing grinding accuracy. Achieving lightweight design and optimal structural layout of machine tool components is a technical challenge in the pursuit of improved stiffness, vibration resistance, and stability.

1.2 Literature Review

Previous studies have employed various methods such as finite element analysis and topology optimization for machine tool structure optimization. However, most of these studies focused on single optimization methods, lacking a comprehensive approach. This research aims to fill this gap by integrating topology optimization, structural bionics, and size optimization to enhance the overall performance of the cycloid gear forming grinding machine column.

1.3 Research Objectives and Methodology

The primary objective of this study is to develop a multi-stage multi-objective optimization method for the machine column. This involves topological optimization to determine the optimal material distribution, structural bionic optimization inspired by natural structures, and size optimization using the response surface model genetic algorithm. The performance of the optimized column will be evaluated through static and dynamic analyses, comparing key parameters such as mass, stress, displacement, and natural frequency with the prototype.

2. Prototype Modeling and Analysis

2.1 Prototype Design and Modeling

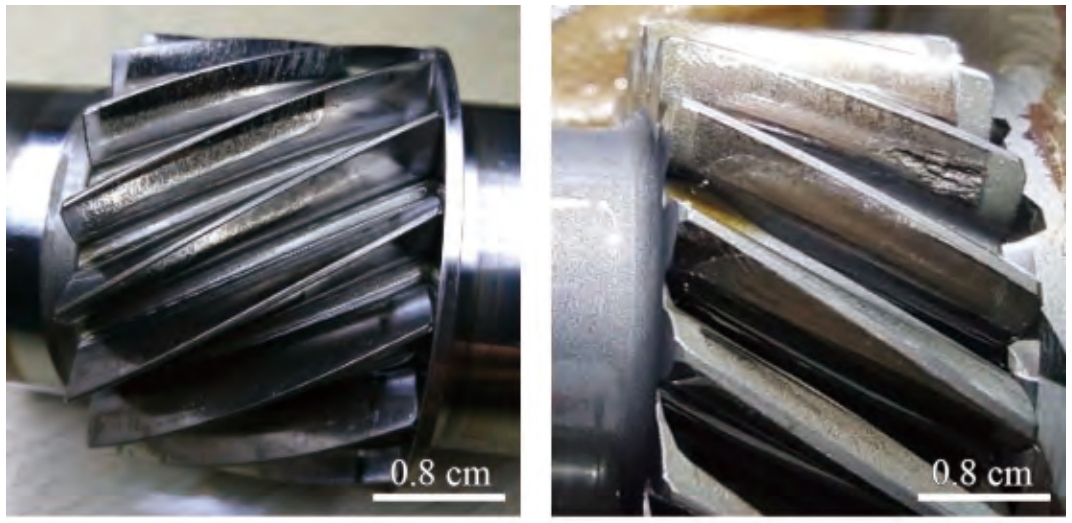

The Y7654A cycloid wheel grinding machine, a representative model in domestic cycloid gear processing, was chosen as a reference for the prototype design. Despite its historical significance, the machine’s lower processing accuracy is attributed to insufficient static and dynamic performance of its structure. A three-dimensional model of the prototype cycloid wheel forming grinding machine was developed, with a focus on the machine column as the key research object due to its influence on the overall machining accuracy.

2.2 Static and Dynamic Analysis of the Prototype Column

- Finite Element Modeling: The column was modeled as a cantilever beam structure in ANSYS. Boundary conditions were applied, including a specific uniform load on the column guide surface and at the top, along with the self-weight of the column. The material was set as gray cast iron with defined density, Poisson’s ratio, and elastic modulus. After meshing, the model consisted of 87,979 nodes and 51,074 elements.

- Static Analysis Results: The maximum stress and deformation displacement of the prototype column were obtained through static analysis. The maximum stress was found to be 0.56073 MPa, and the deformation displacement was 0.0057636 mm.

- Modal Analysis Results: The modal analysis of the machine column was performed, and the first six natural frequencies and corresponding vibration modes were determined. The first-order natural frequency was 183.25 Hz, and the vibration modes provided insights into the column’s dynamic behavior.

3. Multi-Stage Optimization Design

3.1 Topological Optimization of the Column Body

- Optimization Method and Model: Topological optimization was carried out using the ANSYS software. The objective function was set to minimize structural compliance, and the constraint was the material volume fraction. This process aimed to improve the structural layout of the column by determining the optimal distribution of material under complex loads.

- Optimization Results and Analysis: After 28 iterations, the optimization converged, resulting in a significant reduction in column mass. The optimized structure exhibited a clear load transfer path, and the retained design regions with a cell density above 0.4 were deemed suitable for practical manufacturing due to their contribution to stiffness.

3.2 Bionic Structural Optimization of the Column

- Bionic Design Principles: Structural bionics was applied by drawing inspiration from natural structures. The venation of the Victoria amazonica leaf and the petiole of the banana plant were selected as bionic models due to their structural, functional, and load similarities with the machine column.

- Column Bionic Structure Design: Based on the topological optimization results and bionic design principles, internal rib plate structures were designed within the column. The layout of the rib plates was inspired by the venation of the Victoria amazonica leaf, and the structural characteristics of the banana plant petiole were considered to enhance the overall performance of the column.

3.3 Size Optimization Based on the Response Surface Method

- Parameterization Model Establishment: Eight internal structural dimensions of the column were selected as design variables for optimization. These variables included the thickness of various rib plates and the dimensions of the column cavities. The initial values of these parameters were determined by empirical methods, and their ranges were defined based on the maximum and minimum values obtained through the response surface model in ANSYS Workbench.

- Experimental Design and Data Collection: The central composite experimental design (CCD) method was employed to generate 81 sets of data points. These data points were used to establish a response surface model, with the input parameters being the selected column internal dimensions and the output parameters being the first-order natural frequency, mass, maximum stress, and deformation displacement of the column.

- Optimization Using the MOGA Algorithm: Based on the experimental data, a mathematical optimization model was established with the column mass as the objective function and the first-order natural frequency and deformation displacement as constraints. The genetic algorithm in ANSYS Workbench was used to solve the optimization problem, and three sets of optimal structural dimensions were obtained. The third set of dimensions, which had the minimum objective function value under the same constraints, was selected for further comparison with the prototype column.

4. Performance Comparison and Analysis

4.1 Comparison of Static and Dynamic Performance

The static and dynamic performance of the optimized bionic column was compared with that of the prototype column under the same boundary conditions. The results are summarized in the following table:

| Column | Mass (kg) | Natural Frequency (Hz) | Deformation Displacement (mm) | Maximum Stress (MPa) |

|---|---|---|---|---|

| Prototype | 1254.5 | 183.25 | 0.0057636 | 0.56073 |

| Bionic (Optimized) | 1023.7 | 184.09 | 0.0057327 | 0.42876 |

4.2 Optimization Effect Analysis

The optimized column exhibited a 18.4% reduction in mass compared to the prototype, indicating successful lightweight design. The maximum stress decreased by 23.6%, and the deformation displacement reduced by 0.6%, demonstrating improved static performance. Additionally, the first-order natural frequency increased slightly, enhancing the dynamic performance of the column. These results validate the effectiveness of the proposed multi-stage optimization method in enhancing the overall performance of the cycloid gear forming grinding machine column.

5. Conclusion and Future Research

5.1 Research Achievements

This study proposed a novel multi-stage multi-objective optimization method for the cycloid gear forming grinding machine column. Through topological optimization, an optimal material distribution was achieved, providing a new structural layout. Structural bionic optimization, inspired by natural structures, offered innovative design ideas for the column’s rib plates. Size optimization using the response surface model genetic algorithm determined the best internal structural dimensions, resulting in a significant improvement in both lightweight and static-dynamic performance.

5.2 Research Limitations and Future Directions

Although the proposed method has shown excellent results, there are still some limitations. The optimization process could be further refined by considering more complex loading conditions and material properties. Future research could explore the application of advanced materials and manufacturing techniques to further enhance the performance of the machine column. Additionally, the integration of the optimized column into the overall machine tool system and its impact on the machining process could be investigated.

In conclusion, this research provides a valuable contribution to the field of machine tool design and optimization, offering a comprehensive approach to improving the performance of the cycloid gear forming grinding machine column. The findings have practical implications for the manufacturing industry, enabling the production of more efficient and accurate machine tools.