1. Introduction

In the realm of mechanical engineering, gear systems play a pivotal role in power transmission and motion control. Standard cylindrical gears have long been the go – to choice in many applications due to their well – defined design and established manufacturing processes. However, with the increasing complexity and customization requirements of modern industrial equipment, non – standard cylindrical gears are emerging as a crucial component. These non – standard gears are designed to meet specific operating conditions, such as unique load distributions, space constraints, or non – traditional speed ratios, which standard gears simply cannot fulfill.

The design and analysis of non – standard cylindrical gears are far more complex compared to their standard counterparts. The alteration of parameters like pressure angle, addendum, dedendum, and displacement coefficient not only modifies the tooth shape and tooth root transition curve but also significantly impacts the gear’s performance, including tooth surface load – carrying capacity, tooth root bending stress, and overall transmission efficiency. Existing evaluation methods, such as relying on ISO standard gear equivalent empirical formulas or conducting three – dimensional software modeling analyses, are fraught with issues like low accuracy, cumbersome procedures, and inefficiency. This has spurred the need for more advanced and accurate methods for non – standard cylindrical gear design and analysis.

This article delves deep into the construction of non – standard cylindrical gear accurate parametric models. It begins by exploring the background and significance of non – standard cylindrical gears in modern industry. Then, it meticulously details the process of building precise parametric models, including the generation of tooth profiles and transition curves, as well as the creation of parameterized finite – element models. Subsequently, it validates the accuracy of the models through practical examples and showcases the application of these models in gear design optimization. Finally, it looks at the future trends in non – standard cylindrical gear design and analysis, highlighting the potential for further innovation in this field.

2. Background and Significance of Non – standard Cylindrical Gears

2.1 Industrial Demand for Customization

In today’s industrial landscape, the demand for customized machinery is on the rise. Different industries, such as aerospace, automotive, and robotics, have unique requirements for gear systems. For example, in aerospace applications, gears need to operate under extreme conditions of high speed, low weight, and high reliability. Standard cylindrical gears often cannot meet these specific requirements. Non – standard cylindrical gears, on the other hand, can be tailored to fit the exact needs of these applications. They can be designed with specific tooth profiles, dimensions, and material properties to ensure optimal performance in harsh operating environments.

| Industry | Requirements for Gears | Example of Non – standard Gear Application |

|---|---|---|

| Aerospace | High speed, low weight, high reliability | Custom – designed non – standard gears in aircraft engines for efficient power transmission with minimum weight |

| Automotive | Variable load conditions, compact design | Non – standard gears in automatic transmissions to optimize gear ratios for better fuel efficiency and performance |

| Robotics | Precise motion control, high torque – to – weight ratio | Special – shaped non – standard gears in robotic joints for accurate and smooth movement |

2.2 Limitations of Standard Gears

Standard cylindrical gears are designed based on established standards and norms. While they are suitable for a wide range of general applications, they have several limitations when it comes to meeting specialized requirements. The fixed parameters of standard gears, such as pressure angle, addendum, and dedendum, may not be ideal for applications with non – standard load distributions or speed ratios. For instance, in a high – torque – low – speed application, standard gears may experience excessive tooth wear and fatigue due to the mismatch between their design parameters and the actual operating conditions. This can lead to reduced gear lifespan and increased maintenance costs.

2.3 Impact of Parameter Changes on Gear Performance

The parameters of non – standard cylindrical gears, such as pressure angle, addendum, dedendum, and displacement coefficient, have a profound impact on gear performance. A change in the pressure angle can affect the force distribution along the tooth surface, altering the tooth surface load – carrying capacity. An increase in the addendum may improve the contact ratio but could also lead to interference between the teeth. The displacement coefficient can be adjusted to optimize the gear’s geometric characteristics, such as tooth thickness and root strength. Understanding these relationships is crucial for the design and analysis of non – standard cylindrical gears.

| Parameter | Impact on Gear Performance |

|---|---|

| Pressure Angle | Affects force distribution on tooth surface, influencing tooth surface load – carrying capacity |

| Addendum | Can improve contact ratio but may cause tooth interference; impacts gear meshing characteristics |

| Dedendum | Influences tooth root strength and the amount of material available at the root; affects bending stress |

| Displacement Coefficient | Adjusts tooth thickness and root strength, optimizing gear geometric characteristics for specific applications |

3. Precise Parametric Model Construction of Non – standard Cylindrical Gears

3.1 Gear Tooth Profile and Transition Curve

3.1.1 Composition of Gear Tooth Profile

The tooth profile of a gear consists of two main parts: the involute part and the transition curve part. The involute part is responsible for the smooth meshing of gears and is the most common shape for gear teeth in transmission applications. The transition curve, on the other hand, connects the involute part to the tooth root. In non – standard cylindrical gears, accurately determining the shape and dimensions of both the involute and transition curve parts is essential for optimal gear performance.

In an illustration (Figure 1: Composition of Gear Tooth Profile), the involute part and the transition curve part are clearly shown. The involute curve is generated by the rolling of a straight – line (the base circle) along another straight – line (the generating line). The transition curve, which is different for gears processed by different methods (such as extension involute for gears processed by hob and extension epicycloid for gears processed by pinion cutter), ensures a smooth transition between the involute and the tooth root, reducing stress concentration.

3.1.2 Generation of Tooth Profile for Different Machining Methods

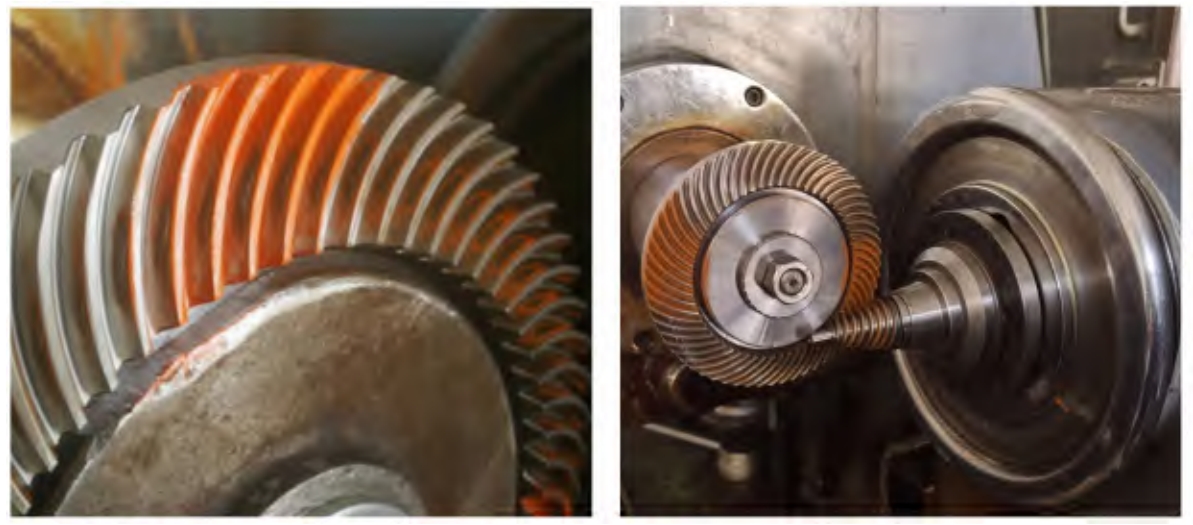

- Roll – cut External Gear Tooth Profile: When a gear is cut by a hob, the tooth profile is generated through a rolling – cutting process. The hob, which resembles a screw – shaped tool with cutting edges, moves along the axis of the gear blank while the gear blank rotates. The relative motion between the hob and the gear blank creates the tooth profile. The geometric relationship during this process is complex but can be described by a series of equations. As shown in Figure 2: Roll – cut External Gear Machining Process, the position of the hob’s cutting edge at each moment determines the shape of the tooth profile. The equations for calculating the coordinates of the tooth profile points take into account parameters such as the modulus of the gear, the pressure angle, the displacement coefficient, and the distance between the hob and the gear blank.

- Pin – made Internal Gear Tooth Profile: For internal gears, the pin – made method is commonly used. In this process, a pin – shaped cutter with teeth similar to the desired internal gear profile is used. The cutter rotates and reciprocates within the gear blank to cut the teeth. The tooth profile of the internal gear is generated based on the motion of the pin – shaped cutter. As depicted in Figure 3: Pin – made Internal Gear Machining Process, the relationship between the cutter’s motion and the gear blank’s rotation is crucial for determining the accurate tooth profile. The equations for calculating the internal gear tooth profile coordinates consider parameters specific to the pin – shaped cutter, such as its radius, pressure angle, and the number of teeth.

3.2 Parameterized Construction of Non – standard Cylindrical Gears

3.2.1 Parameterized Unit Construction

To construct a parameterized model of a non – standard cylindrical gear, the first step is to generate the tooth profile equations. Based on the equations derived from the machining processes described above, programs can be written to calculate the coordinates of discrete points on the tooth profile. These discrete points are then used to create a finite – element mesh.

In Figure 4: Generation of Discrete Points on Gear Tooth Profile, the process of generating discrete points is illustrated. The program divides the tooth profile into a series of small segments, and for each segment, it calculates the coordinates of the endpoints based on the tooth profile equations. The number of discrete points can be adjusted according to the required accuracy of the model. A higher number of discrete points will result in a more accurate representation of the tooth profile but will also increase the computational cost.

After obtaining the discrete points, a finite – element mesh is created. The choice of element type is crucial for the accuracy and efficiency of the simulation. In this case, the linear reduced – integration element (C3D8R) is often used. This element type has several advantages, such as accurate displacement calculation and low sensitivity to mesh distortion. As shown in Figure 5: Finite – Element Mesh of Non – standard Cylindrical Gear, the C3D8R elements are arranged to form a mesh that closely follows the shape of the gear tooth profile. The nodes of the elements are located at the discrete points calculated earlier, ensuring a precise representation of the gear geometry.

3.2.2 Parameterized Finite – Element Model Settings

In order to make the finite – element model truly parameterized, two common methods can be used in software like ABAQUS. The first method is to use a script file with Python language. Python, being a GUI – oriented language, can automate the modeling and analysis process. It allows users to write a series of commands that represent each step of the model creation, from importing the part to setting the material properties, boundary conditions, and analyzing the model. The second method is to use an Inp file with Fortran language. The Inp file contains all the data related to the model, including the geometry, material properties, contact conditions, and analysis steps. Although the second method requires a deeper understanding of the software’s language, it can also provide a more direct and efficient way to create a parameterized model.

| Method | Language | Advantages | Disadvantages |

|---|---|---|---|

| Script File | Python | Strong automation ability, easy to use for general users | May require some programming knowledge; less direct access to model data |

| Inp File | Fortran | Direct access to model data, suitable for users with in – depth software knowledge | Steeper learning curve; more complex to write compared to Python scripts |

In practice, both methods can be implemented, and the more suitable one can be chosen based on the specific requirements and user preferences. For example, if the user wants a highly automated process with less programming complexity, the Python – based script file method may be preferred. On the other hand, if the user needs to fine – tune the model data and has a good understanding of Fortran, the Inp file method may offer more flexibility.

4. Model Accuracy Verification through Tooth Profile Modification

4.1 Selection of Verification Example

To verify the accuracy and feasibility of the constructed non – standard cylindrical gear parametric model, a practical example of a non – standard planetary transmission system is chosen. This system contains both internal and external meshing pairs, which can comprehensively test the performance of the model in different meshing conditions. The basic parameters of the planetary transmission system are listed in Table 1: Basic Parameters of Planetary Transmission System.

| Parameter | Sun Gear | Planet Gear | Ring Gear |

|---|---|---|---|

| Number of Teeth | 48 | 55 | 162 |

| Modulus (mm) | 3.8 | 3.8 | 3.8 |

| Pressure Angle (°) | 22.5 | 22.5 | 22.5 |

| Tooth Width (mm) | 90 | 88 | 88 |

| Sun Gear Rotation Speed (r/min) | 1128.0 | – | – |

| Input Power (kW) | 2985.8 | – | – |

| Input Torque (N·m) | 25278.7 | – | – |

| Single – path Meshing Force (N) | 60003.2 | – | – |

4.2 Comparison of Tooth Surface Contact Stress before and after Tooth Profile Modification

A high – precision parabola micro – tooth profile modification is used as an example for comparison. The tooth surface contact stress before and after the modification is analyzed. In Figure 6: Comparison of Tooth Surface Contact Stress before and after Modification for External Meshing, and Figure 7: Comparison of Tooth Surface Contact Stress before and after Modification for Internal Meshing, the distribution of tooth surface contact stress can be clearly seen.

Before the tooth profile modification, the contact stress distribution may be uneven, with some areas experiencing higher stress concentrations. After the modification, the contact stress is more evenly distributed, reducing the risk of tooth failure. This indicates that the parametric model can accurately predict the changes in gear performance caused by tooth profile modification.

In addition, when there is an axis – angle error of 1′ in the non – standard gear, the tooth surface contact stress before and after the tooth profile modification is also compared. The results show that the parametric model can effectively simulate the influence of such errors on gear performance. As shown in Figure 8: Tooth Surface Contact Stress with Axis – Angle Error before Modification and Figure 9: Tooth Surface Contact Stress with Axis – Angle Error after Modification, the model can accurately reflect how the tooth profile modification can mitigate the negative effects of the axis – angle error on the tooth surface contact stress.

5. Application of Non – standard Cylindrical Gear Parametric Models in Gear Design Optimization

5.1 Parameter Design

The accurate parametric model of non – standard cylindrical gears provides a powerful tool for gear parameter design. Designers can adjust various parameters, such as the number of teeth, modulus, pressure angle, and displacement coefficient, and immediately observe the impact on gear performance through the model. For example, by changing the number of teeth, the speed ratio and contact ratio of the gear pair can be adjusted. The modulus affects the size and strength of the gear teeth. The pressure angle can be optimized to improve the force transmission efficiency. The displacement coefficient can be used to balance the tooth thickness and root strength.

| Parameter | Adjustment Purpose | Impact on Gear Performance |

|---|---|---|

| Number of Teeth | Adjust speed ratio and contact ratio | Changes the gear ratio and the number of teeth in contact simultaneously; affects meshing stability |

| Modulus | Adjust gear tooth size and strength | Larger modulus results in stronger teeth but also increases gear size; smaller modulus for more compact designs with potentially lower strength |

| Pressure Angle | Improve force transmission efficiency | Different pressure angles change the direction and magnitude of forces on the tooth surface; affects load – carrying capacity and friction |

| Displacement Coefficient | Balance tooth thickness and root strength | Adjusts the position of the tooth profile along the pitch circle, optimizing tooth geometry for specific load conditions |

5.2 Process Adjustment

In the manufacturing process of non – standard cylindrical gears, the parametric model can be used to optimize the machining process. By simulating different machining parameters, such as cutting speed, feed rate, and tool geometry, manufacturers can predict the quality of the machined gear and make adjustments accordingly. For example, if the simulation shows that a certain cutting speed will cause excessive tool wear or poor surface finish, the cutting speed can be adjusted to a more suitable value. This not only improves the manufacturing quality but also reduces production costs and increases production efficiency.

5.3 Tooth Profile Modification Design

Tooth profile modification is an important aspect of gear design optimization. The parametric model can accurately simulate the effects of different tooth profile modification methods, such as parabola micro – tooth profile modification, on gear performance. Designers can use this information to select the most appropriate tooth profile modification method for a specific application. For example, in a high – speed and high – load application, a more aggressive tooth profile modification may be required to reduce vibration and noise and improve the durability of the gear.

6. Future Trends in Non – standard Cylindrical Gear Design and Analysis

6.1 Integration with Advanced Manufacturing Technologies

With the rapid development of advanced manufacturing technologies such as 3D printing and computer – numerical control (CNC) machining, non – standard cylindrical gear design is expected to be more closely integrated with these technologies. 3D printing allows for the production of complex – shaped gears with customized geometries that are difficult to manufacture using traditional methods. CNC machining can achieve high – precision manufacturing based on the accurate models designed by parametric software. This integration will enable more efficient production of non – standard cylindrical gears with higher quality and lower costs.

6.2 Multiphysics and System – level Analysis

In the future, non – standard cylindrical gear design will not only focus on the mechanical aspects but also consider multiphysics factors such as heat transfer, fluid – structure interaction, and tribology. For example, in high – speed gear systems, heat generation due to friction can significantly affect gear performance and lifespan. By considering these multiphysics factors in the design process, more comprehensive and accurate models can be developed. Additionally, system – level analysis, which takes into account the interaction between gears and other components in a mechanical system, will become more common. This will help designers optimize the overall performance of the mechanical system rather than just the individual gears.

6.3 Development of Intelligent Design Tools

As artificial intelligence (AI) and machine learning (ML) technologies continue to advance, intelligent design tools for non – standard cylindrical gears are likely to emerge. These tools can analyze a large amount of design data and performance information to provide designers with optimized design solutions. For example, an AI – based design tool can learn from previous successful gear designs and predict the performance of new designs based on input parameters. This will greatly reduce the design time and improve the design quality, making the design process more efficient and intelligent.

7. Conclusion

Non – standard cylindrical gears play an increasingly important role in modern industrial applications. The construction of accurate parametric models for these gears is a crucial step in understanding their performance and optimizing their design. Through the methods described in this article, including the precise generation of tooth profiles and transition curves, the construction of parameterized finite – element models, and the verification of model accuracy, designers can create high – quality non – standard cylindrical gears that meet specific application requirements.

The application of these parametric models in gear design optimization, such as parameter design, process adjustment, and tooth profile modification design, provides practical solutions for improving gear performance. Looking ahead, the future trends in non – standard cylindrical gear design, including integration with advanced manufacturing technologies, multiphysics and system – level analysis, and the development of intelligent design tools, offer great potential for further innovation and improvement in this field. As the demand for customized and high – performance gear systems continues to grow, non – standard cylindrical gears will undoubtedly become an even more critical component in the mechanical engineering industry.进入 AI 阅读