This article focuses on non – standard cylindrical gears, which have a wide range of applications in modern industrial equipment due to their ability to meet customization requirements. It details the construction process of precise parametric models for non – standard cylindrical gears, analyzes the existing problems in traditional evaluation methods, and validates the accuracy and feasibility of the new model through practical examples. The research aims to provide a reliable technical basis for the design, process adjustment, and tooth modification of non – standard cylindrical gears.

1. Introduction

In the field of mechanical transmission, gear systems play a crucial role. With the continuous development of industrial equipment, the requirements for gear performance are becoming more and more diverse. Standard cylindrical gears often cannot meet the specific needs of various working conditions, such as special load – bearing requirements, limited installation space, and high – precision transmission requirements. Non – standard cylindrical gears, with their customizable parameters, have gradually become an important choice in modern mechanical design.

However, the design and analysis of non – standard cylindrical gears face many challenges. The change of parameters such as pressure angle, addendum height, dedendum height, and displacement coefficient will lead to changes in tooth shape and tooth root transition curve, which in turn affect the tooth surface bearing capacity, tooth root bending stress, and transmission performance. Traditional evaluation methods, such as those based on ISO standard gear equivalent empirical formulas and 3D software modeling analysis, have problems such as cumbersome steps, low efficiency, and low accuracy. Therefore, it is of great significance to construct a precise parametric model for non – standard cylindrical gears.

2. Traditional Evaluation Methods for Non – standard Cylindrical Gears and Their Problems

2.1 Traditional Evaluation Methods

- Based on ISO Standard Gear Equivalent Empirical Formulas This method roughly estimates and evaluates the performance and parameters of non – standard gear pairs by referring to the empirical formulas of ISO standard gears. For example, when calculating the tooth root bending stress of non – standard gears, it may use formulas similar to those of standard gears, but with some correction factors. However, these correction factors are often based on limited experimental data and simplifying assumptions.

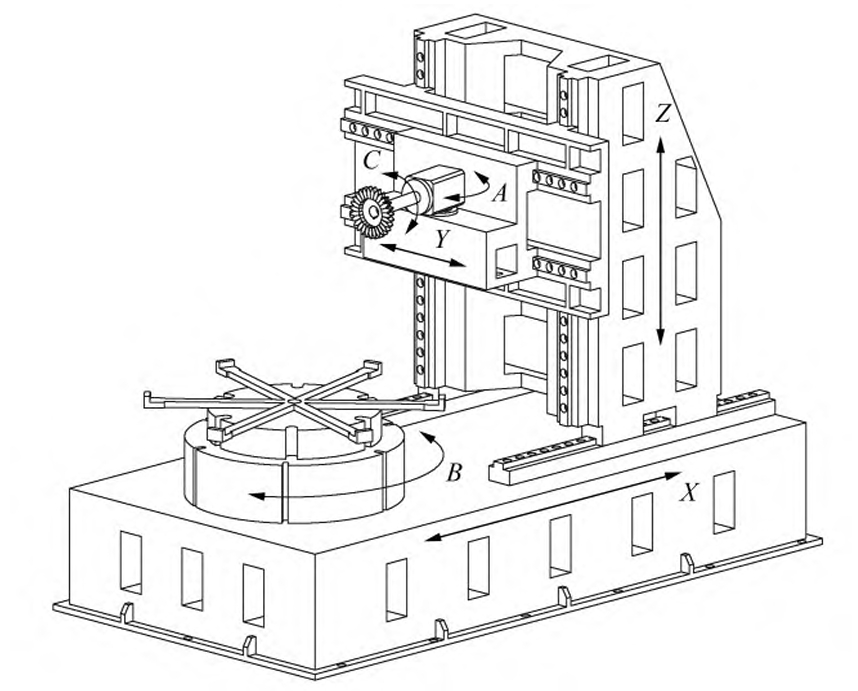

- 3D Software Modeling Analysis This approach involves solving the mathematical model of the tooth profile curve of non – standard gear pairs, creating a 3D model through modeling settings, and then performing operations such as mesh generation, boundary condition setting, solution algorithm selection, and analysis environment definition in finite – element software to obtain relevant results. For instance, in software like SolidWorks or ANSYS, engineers first create a 3D model of the gear, and then use the finite – element analysis module to analyze its mechanical properties.

2.2 Problems with Traditional Methods

- Low Accuracy The results of methods based on empirical formulas are often inaccurate because they cannot fully consider the complex geometric and mechanical characteristics of non – standard gears. The simplified assumptions in these formulas lead to large errors when applied to non – standard gears with significant parameter deviations from standard gears.

- Cumbersome and Inefficient Modeling Process The 3D software modeling analysis method requires a lot of manual operations. For example, when the gear parameters change, the entire modeling process, including rebuilding the model, re – setting the mesh, and re – defining the boundary conditions, needs to be repeated, which is time – consuming and labor – intensive.

| Problem | Description | Impact |

|---|---|---|

| Low accuracy | Empirical formulas rely on simplified assumptions and limited data | Inaccurate evaluation of gear performance, may lead to design failures |

| Cumbersome modeling | Repeated modeling steps for parameter changes | Time – consuming, reduces design efficiency |

| Difficult solution | Complex mathematical models and large – scale calculations | High – end computing resources required, long calculation time |

3. Precise Parametric Model Construction for Non – standard Cylindrical Gears

3.1 Precise Tooth Profile Construction

- Roll – Cut External Gear Tooth Profile Equation The tooth profile of an external gear cut by a hob is composed of an involute part and a transition curve part. When constructing the tooth profile equation, we first establish a coordinate system. As shown in Figure 1 (Roll – cut External Gear Coordinate System), let XPY be the fixed rectangular coordinate system, and \(X_{1}O_{1}Y_{1}\) be the coordinate system on the rack cutter. [Insert Figure 1: Roll – cut External Gear Coordinate System here] During the gear – cutting process, the rack cutter moves leftward along the \(O_{1}X_{1}\) axis, and the gear’s pitch circle and the rack’s rolling pitch line perform pure rolling. The coordinates of the tooth profile cutting point B on the straight – edge part of the rack cutter can be derived based on geometric relationships. The formula for calculating the coordinates of point B takes into account parameters such as the module m of the rack, the displacement coefficient \(\xi\), the pressure angle \(\alpha_{0}\) of the rack, and the distance S from the \(O_{1}Y_{1}\) axis of the rack to the fixed coordinate PY axis. For the transition curve part formed by the rounded – edge of the rack cutter, we need to determine the coordinates of the cutting point K. The radius of curvature of the rounded – edge of the cutting edge is \(R_{T}\). By calculating the distances E and F related to the rounded – edge and using trigonometric functions, we can obtain the coordinates of point K. Finally, through coordinate transformation, we can determine the tooth profile coordinates and transition curve coordinates of the processed gear.

- Insert – Made Internal Gear Tooth Profile Equation The internal gear profile is generated by the involute of the pinion cutter. First, we assume that the pinion cutter’s tooth profile is processed by a rack. As shown in Figure 2 (Generation of Pinion Cutter Tooth Profile), we define the coordinate systems \(S_{1}(x_{1}, y_{1})\) and \(S_{j}(x_{j}, y_{j})\) associated with the pinion cutter and the frame respectively. [Insert Figure 2: Generation of Pinion Cutter Tooth Profile here] The equation of the pinion cutter’s tooth profile curve can be derived through the meshing process of the rack and the pinion cutter. Considering parameters such as the pitch circle radius \(r_{p1}\) of the pinion cutter, the rotation angle \(\theta_{1}\) of the pinion cutter when the rack moves a certain distance, the pressure angle \(\alpha_{1}\) at the pitch circle of the pinion cutter, the module m, and the displacement coefficient \(x_{c}\) of the pinion cutter. Since the original tooth profile of the pinion cutter may have a sharp corner at the tooth tip, which will cause stress concentration in the internal gear ring, we replace the sharp – corner part with a rounded – corner \(M_{1}N_{2}\). By determining the center \(Q_{1}\) of the rounded – corner through geometric methods and calculating the coordinates of the cutting point \(K_{1}\) of the rounded – corner, and then performing coordinate transformation between the tool coordinate system and the workpiece coordinate system, we can obtain the involute equation and transition curve equation of the internal gear tooth profile.

3.2 Parametric Construction

- Parametric Unit Construction Based on the obtained tooth profile curve equations, we can write corresponding programs. By setting the required number of meshes and equally dividing, we can accurately obtain the coordinates of discrete points on the end face of non – standard internal and external cylindrical gears. As shown in Figure 3 (Discrete Nodes on the End Face of Single – Tooth of Internal and External Gears), these discrete points serve as the basis for constructing the finite – element model. [Insert Figure 3: Discrete Nodes on the End Face of Single – Tooth of Internal and External Gears here] We choose the linear reduced – integration unit (C3D8R) in ABAQUS to build the finite – element model of a single – tooth of non – standard internal and external gears. This unit has high accuracy in calculating displacements and is less affected by mesh distortion. After constructing the single – tooth model, we can obtain the full – tooth finite – element model by circumferentially rotating and arraying and merging the tolerances.

- Parametric Finite – Element Model Setting ABAQUS provides two methods for parametric settings: using script files with Python language and using Inp files with Fortran language. The Python – based method is more automated as it can realize the automatic reproduction of operations. It contains the execution commands for each step and is suitable for users who want to quickly implement parametric design. The Fortran – based Inp file method directly faces the model itself and contains various information about the model, but it requires the operator to have a deep understanding of the ABAQUS software platform language. After comparing the two methods, the Python – based method is selected in this study.

4. Model Accuracy Modification Verification

4.1 Verification Example

To verify the accuracy and feasibility of the established model, a non – standard planetary transmission system is taken as an example. The relevant parameters of this planetary transmission system are shown in Table 1 (Basic Parameters of the Planetary Gear Train).

| Parameter | Sun Gear | Planet Gear | Internal Gear Ring |

|---|---|---|---|

| Number of Teeth | 48 | 55 | 162 |

| Module / mm | 3.8 | 3.8 | 3.8 |

| Pressure Angle / (°) | 22.5 | 22.5 | 22.5 |

| Tooth Width / mm | 90 | 88 | 88 |

| Sun Gear Rotation Speed / (r/min) | 1128.0 | – | – |

| Input Power / kW | 2985.8 | – | – |

| Input Torque / (N·m) | 25278.7 | – | – |

| Single – Path Meshing Force / N | 60003.2 | – | – |

4.2 Verification Method

We take the parabola micro – modification with high – precision requirements as an example for comparison. By comparing the tooth surface contact stress before and after modification, as shown in Figure 4 (Comparison of Tooth Surface Contact Stress Before and After Modification of External Meshing) and Figure 5 (Comparison of Tooth Surface Contact Stress Before and After Modification of Internal Meshing), we can observe the changes in the tooth surface contact stress. [Insert Figure 4: Comparison of Tooth Surface Contact Stress Before and After Modification of External Meshing here] [Insert Figure 5: Comparison of Tooth Surface Contact Stress Before and After Modification of Internal Meshing here] In addition, when there is an axis – angle error of 1′ in the non – standard gear, we also compare the tooth surface contact stress before and after tooth surface modification, as shown in Figure 6 (Comparison of Tooth Surface Contact Stress of External Meshing with Axis – Angle Error Before and After Modification) and Figure 7 (Comparison of Tooth Surface Contact Stress of Internal Meshing with Axis – Angle Error Before and After Modification). [Insert Figure 6: Comparison of Tooth Surface Contact Stress of External Meshing with Axis – Angle Error Before and After Modification here] [Insert Figure 7: Comparison of Tooth Surface Contact Stress of Internal Meshing with Axis – Angle Error Before and After Modification here]

4.3 Verification Results

The comparison results show that the parametric model established in this article is accurate and efficient. It can provide technical support for non – standard gear parameter design, process adjustment, and tooth modification. The model can accurately reflect the changes in tooth surface contact stress under different conditions, which is of great significance for optimizing the design of non – standard cylindrical gears.

5. Applications of Non – standard Cylindrical Gears in Different Industries

5.1 Aerospace Industry

In aircraft engines and helicopter transmission systems, non – standard cylindrical gears are widely used. For example, in helicopter main gearboxes, non – standard gears can be designed according to specific load – bearing requirements and space limitations. The precise parametric model can help engineers accurately analyze the performance of gears under high – speed and high – load conditions, ensuring the reliability and safety of the transmission system.

5.2 Automotive Industry

In the automotive field, especially in electric vehicle transmissions, non – standard cylindrical gears are used to meet the requirements of different torque and speed ratios. The parametric model can be used to optimize the gear design, reduce noise and vibration during gear meshing, and improve the overall performance of the vehicle.

5.3 Heavy – Machinery Industry

In large – scale construction machinery and mining equipment, non – standard cylindrical gears need to withstand large – scale loads. The accurate parametric model can help designers design gears with high – strength and long – life, improving the durability and stability of heavy – machinery.

6. Future Developments and Challenges

6.1 Future Developments

- Integration with Advanced Manufacturing Technologies With the development of technologies such as 3D printing and CNC machining, non – standard cylindrical gears can be manufactured more precisely and efficiently. The parametric model can be directly integrated with these manufacturing technologies, enabling seamless connection between design and manufacturing.

- Multi – physical Field Coupling Analysis In the future, non – standard cylindrical gear models will be combined with multi – physical field analysis, such as thermal – structural coupling and fluid – structure interaction analysis. This will help engineers comprehensively understand the performance of gears in complex working environments.

6.2 Challenges

- High – Dimensional Parameter Optimization As the number of parameters in non – standard cylindrical gears increases, how to optimize multiple parameters simultaneously to achieve the best performance is a challenge. Traditional optimization algorithms may face difficulties in dealing with high – dimensional parameter spaces.

- Model Uncertainty and Reliability There are uncertainties in factors such as material properties and manufacturing errors. How to consider these uncertainties in the parametric model and ensure the reliability of the model is an important issue that needs to be addressed.

7. Conclusion

This article comprehensively expounds on the construction of precise parametric models for non – standard cylindrical gears. By analyzing traditional evaluation methods and their problems, a new method for constructing parametric models is proposed. Through the establishment of tooth profile equations, parametric construction, and model accuracy verification, it is proven that the new model is accurate and efficient. The applications of non – standard cylindrical gears in different industries are also discussed, and future development trends and challenges are analyzed. The research results of this article provide important technical support for the design and application of non – standard cylindrical gears in modern mechanical engineering.