Installation error is a factor that is affected by changes in production conditions, environmental factors and time. It is characterized by randomness and uncertainty and belongs to uncontrollable factors. In the actual operation process of spiral bevel gear, the installation error cannot be completely eliminated, and the robust optimization design method can only be used to minimize the sensitivity of spiral bevel gear transmission to installation error, so as to ensure the service life of spiral bevel gear.

Based on this, Chen Peng and others considered the impact of installation error on the robustness of spiral bevel gears, and established 6 σ The mathematical model of robust optimization design takes the second-order contact parameters and installation errors as the design variables, takes the quantified tooth surface contact mark features as the constraint conditions, uses the Monte Carlo method to sample, uses the multi-island genetic algorithm to optimize the second-order contact parameters, and carries out the robust design that is not sensitive to installation errors. The results show that the optimized second-order contact parameters improve the robustness under the uncertainty of installation error by more than 99%, and the sensitivity of spiral bevel gears to installation error during meshing is reduced by more than 30%. In order to improve the loading and meshing quality of spiral bevel gears, Mu Y et al. established a mathematical optimization model to reduce transmission error and meshing impact, proposed a multi-objective optimization design method, obtained the processing parameters of spiral bevel gears, and used genetic algorithm to inverse the optimized processing parameters. The simulation results show that the loading and transmission error of optimized spiral bevel gears is reduced by 31 66%, the dynamic meshing impact is also significantly reduced, as shown in the figure.

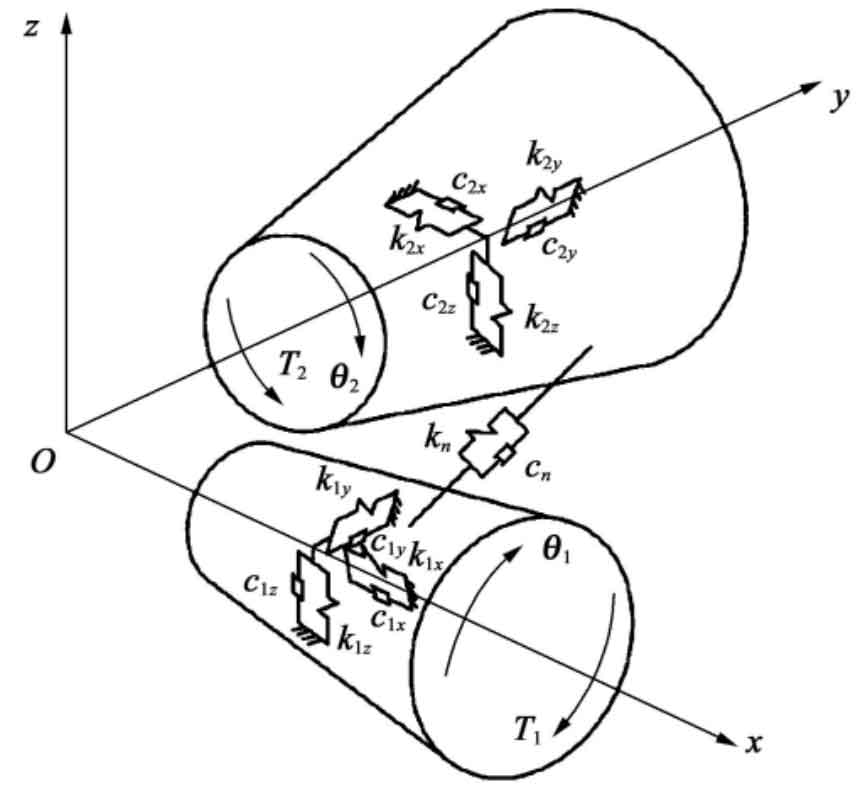

Su Jinjin et al. studied the error sensitivity optimization design, took the total curvature of the differential surface of the spiral bevel gear as the sensitivity coefficient, analyzed the installation error sensitivity at the design reference point, and obtained the processing parameters of the small wheel by optimizing the first derivative, the direction of the contact trace, the second order variation coefficient, and the third order variation coefficient, which reduced the sensitivity of the processed tooth surface to the installation error, and improved the meshing transmission performance. Su Jinzhan et al. take the sum of the quantified print area and the sensitivity coefficient of the horizontal position of the print as the optimization model, take the pinion cutting parameters as the design variables, take the continuity and amplitude of the transmission error curve as the constraint conditions, improve the machining parameters of spiral bevel gears, and define the sensitivity matrix, so that the sensitivity of the tooth surface print to the installation error is reduced when the installation error exists, The robust optimization design of spiral bevel gears is realized. Tang Jinyuan et al. established a model of spiral bevel gears including installation error sensitivity and tolerance, and pointed out the relationship between the model and the contact quality and cutting parameters of spiral bevel gears, which has certain guiding significance for improving the contact performance of spiral bevel gears.

Many scholars have done some research on the robust optimization design of spiral bevel gears including installation errors, but due to the uncertainty of installation errors, the accuracy and speed in the optimization design solution process are relatively low, and the improvement of accuracy and speed needs further research. At present, we have seen relatively few relevant documents, which indicates that the research is at an early stage and needs to be further explored.