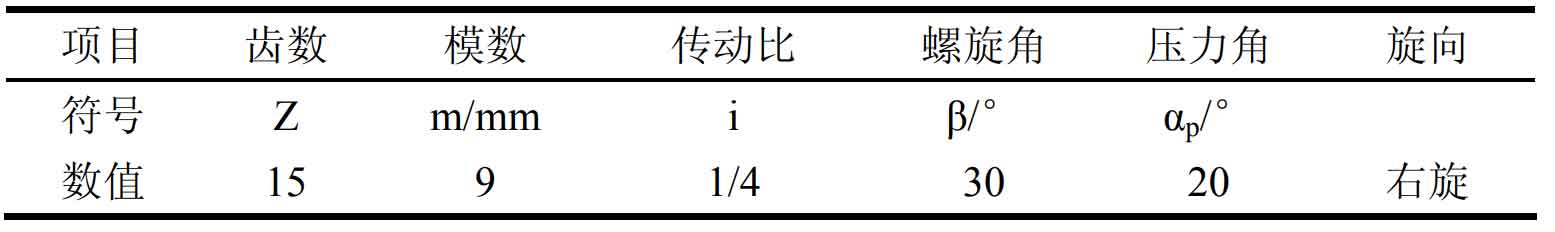

Taking the spiral bevel gear with 15 teeth and 9 modulus as an example, the parameter design of gear blank and the establishment of simulation machining model are carried out. The parameters of bevel gear blank are divided into original parameters and calculation parameters, and the original parameters are shown in Table 1.

According to the original parameters of spiral bevel gear blank in Table 1, calculate other relevant parameters of spiral bevel gear blank:

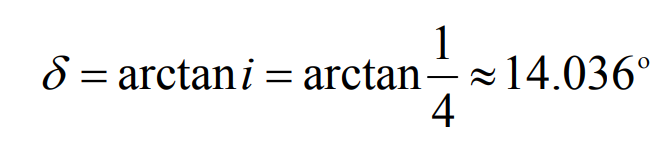

Pitch cone angle of spiral bevel gear:

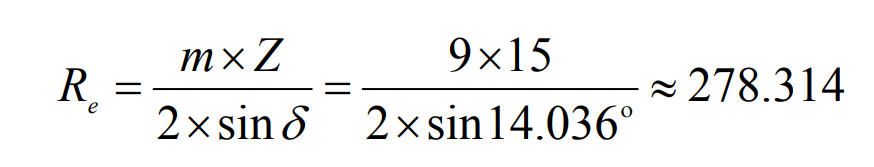

Outer pitch of spiral bevel gear:

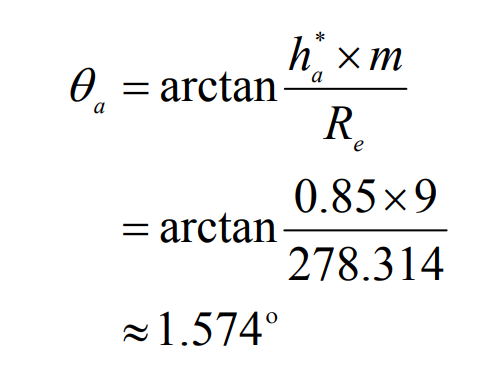

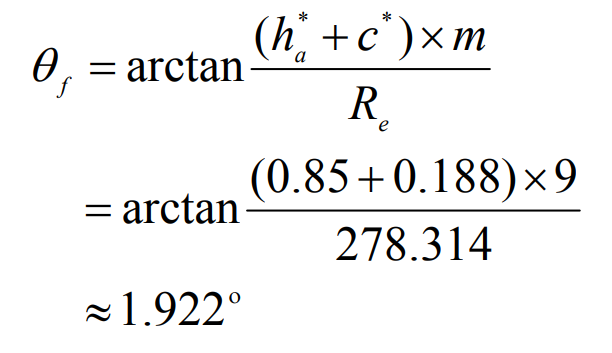

Addendum angle of spiral bevel gear:

Root angle of spiral bevel gear:

Root cone angle of spiral bevel gear:

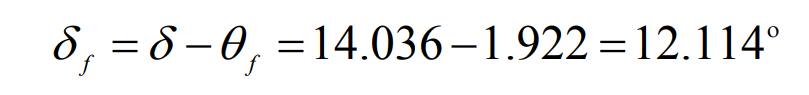

Base cone angle of spiral bevel gear:

Due to the calculated root cone angle δ F < base cone angle δ b. The root cone angle of tapered spiral bevel gear must be greater than or equal to the base cone angle, so the root cone angle is taken δ The angle value of F is 13.174 °.

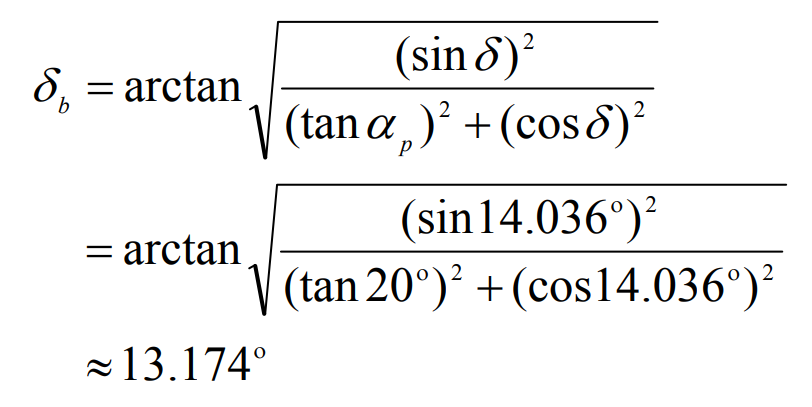

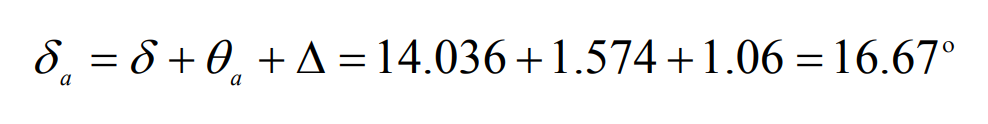

Bevel angle of spiral bevel gear surface:

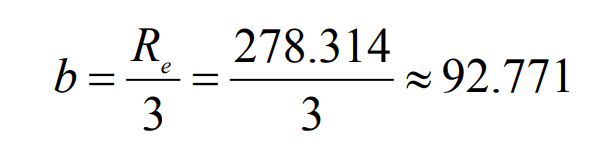

Tooth width of spiral bevel gear:

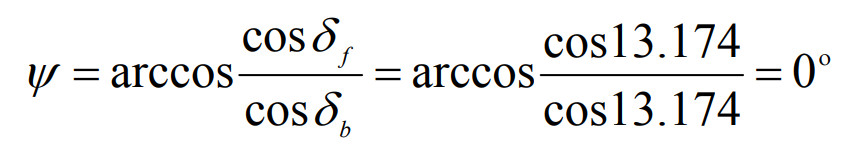

Adjustment angle of spiral bevel gear:

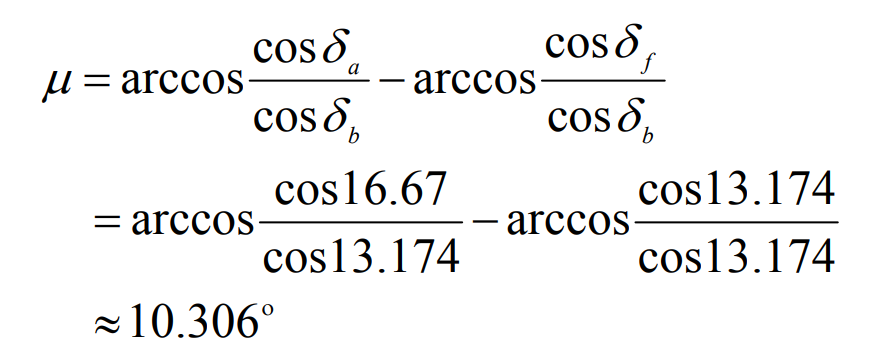

Cutting area angle of spiral bevel gear:

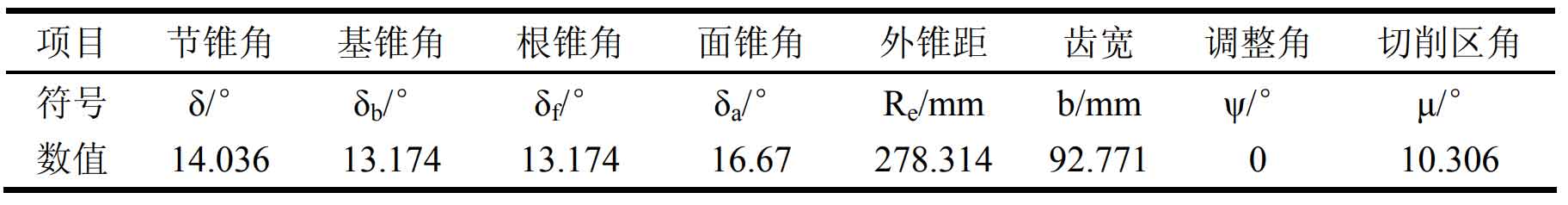

The key parameters of spiral bevel gear calculated above are listed in the table. The calculation parameters of spiral bevel gear are shown in Table 2.

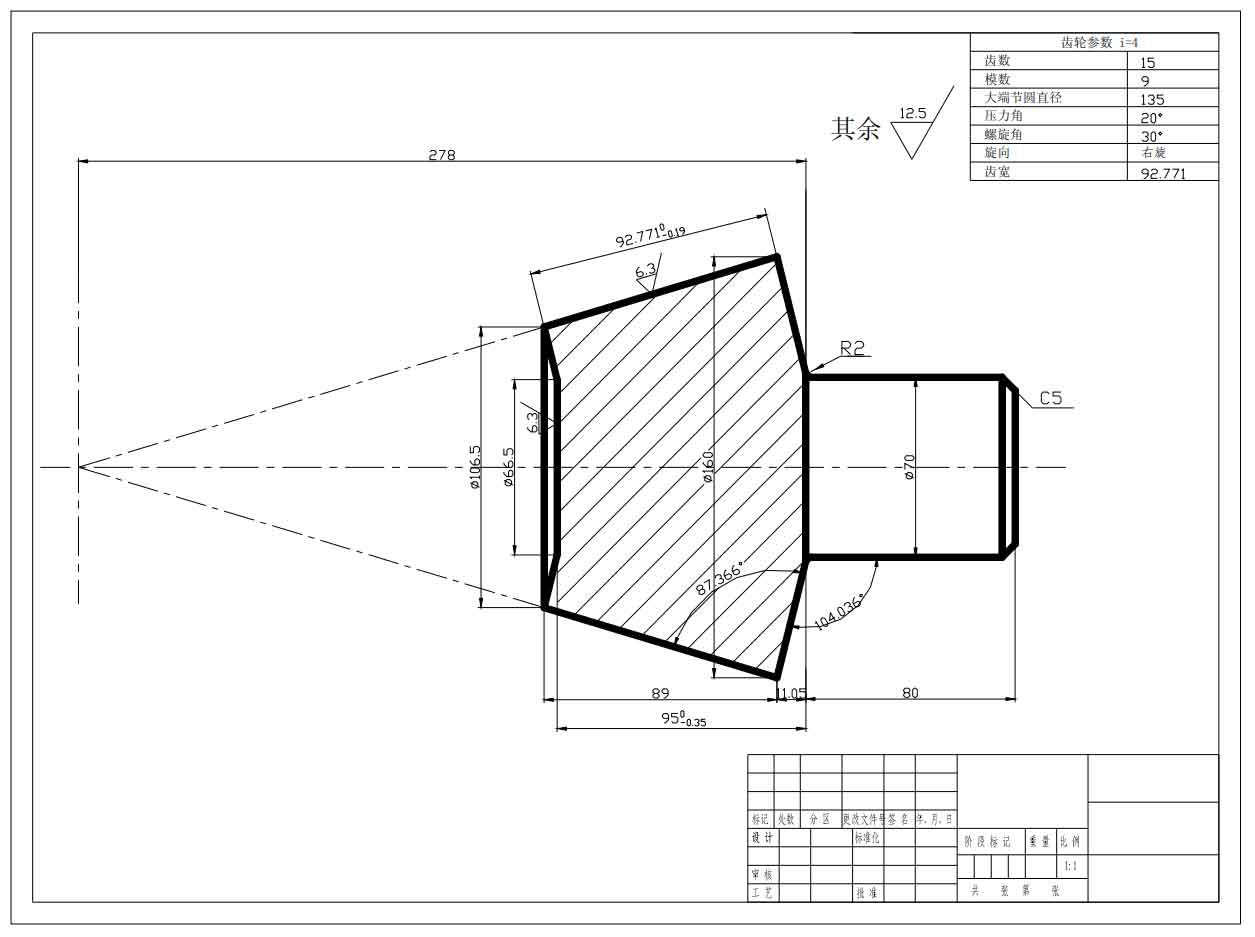

According to the original parameters and calculated parameters of spiral bevel gear blank, the engineering drawing of spiral bevel gear blank is drawn by CAD software, as shown in Figure 1.

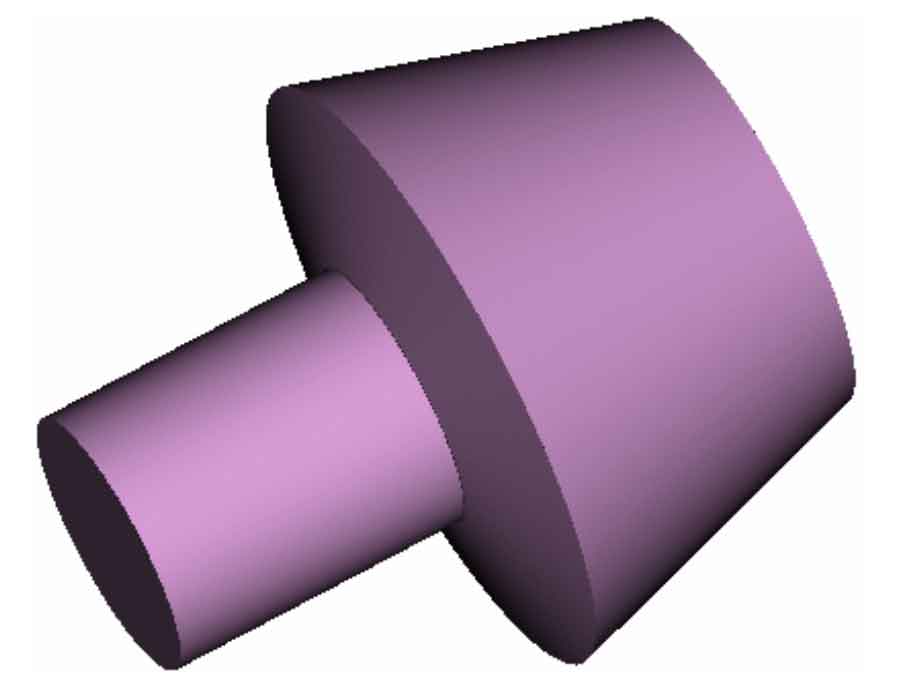

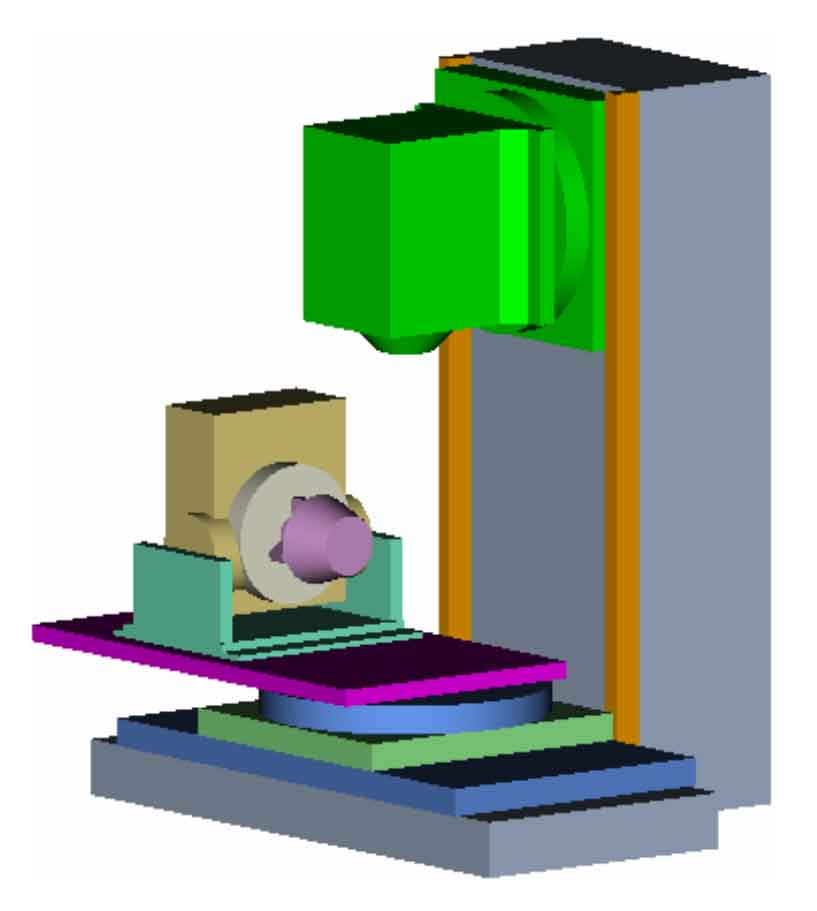

According to the engineering drawing of spiral bevel gear blank, the gear blank model of spiral bevel gear is established in the stock component of VERICUT model of gear cutting machine tool. The VERICUT model of the gear blank is shown in Figure 2. Restrict the movement and rotation of the spiral bevel gear blank to make its rotation axis coincide with the NC rotation axis of the tilting table, and install it on the fixture of the gear cutting machine, as shown in Figure 3.