The process analysis of shaft gears involves understanding and describing the steps and methods used in the manufacturing process of gears mounted on shafts. This analysis aims to optimize the production process, ensure high-quality gears, and enhance overall efficiency. Below are the key steps involved in the process analysis of shaft gears:

1. Material Selection: The first step is selecting the appropriate material for the gears based on the application requirements. Factors like load capacity, wear resistance, and durability are considered during material selection.

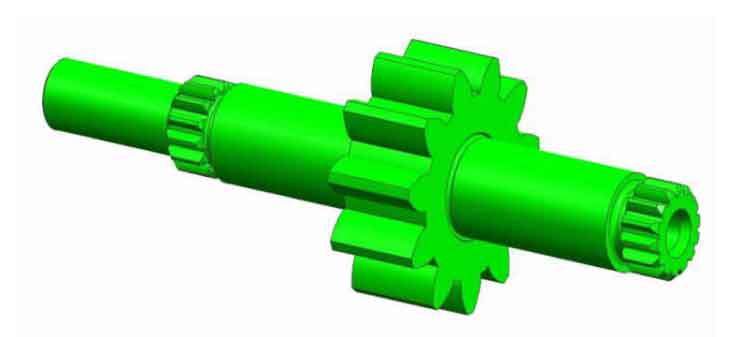

2. Gear Design: The gear design phase involves determining the gear specifications, such as tooth profile, pressure angle, module, number of teeth, and gear ratio. Design engineers use computer-aided design (CAD) software to create detailed gear models.

3. Gear Cutting Method: The next step is choosing the gear cutting method. Common methods include hobbing, milling, shaping, and grinding. Each method has its advantages and is selected based on factors such as gear type, quantity, accuracy, and surface finish requirements.

4. Gear Manufacturing: The chosen gear cutting method is employed to manufacture the gears. For instance, in hobbing, a hob cutter is used to produce the gear teeth by rotating the workpiece against the hob. For milling or shaping, the gear teeth are cut using a gear-shaped cutting tool.

5. Heat Treatment: After gear cutting, heat treatment is often performed to enhance the gears’ hardness and strength. Processes like carburizing, quenching, and tempering are used to achieve the desired material properties.

6. Quality Control: Throughout the process, quality control measures are implemented. This involves inspecting gear dimensions, tooth profiles, surface finish, and other critical features to ensure they meet design specifications.

7. Gear Shaft Assembly: Once the gears are manufactured, they are mounted on the shafts through various methods like press-fitting, splines, or keyways, depending on the gear and shaft design.

8. Gearbox Assembly: In some cases, the shaft gears are assembled into gearboxes or mechanical systems to complete the power transmission mechanism.

9. Performance Testing: Before final use, the assembled gear system is tested for performance, efficiency, and reliability. This may involve load testing, durability testing, and noise/vibration analysis.

10. Maintenance and Inspection: After deployment, regular maintenance and inspection are performed to ensure the gears remain in good condition and continue to function optimally.

Process analysis helps identify bottlenecks, potential improvements, and ways to streamline the manufacturing process of shaft gears. By optimizing each step, manufacturers can produce high-quality gears efficiently, leading to cost savings and improved product performance.