The component with fracture failure is the passive gear of large bulldozer. The heat treatment process is quenching and tempering after carburizing.

After heat treatment, due to the deformation of the gear, local heating is used to correct and then tempering. Four months later, the gear was found to be cracked when grinding the inner hole.

According to the fracture morphology, it can be concluded that the fracture failure of the passive gear is due to the embrittlement of the component due to the high hydrogen content in the component matrix and the cracking under the combined action of large tensile stress. The reason for the high hydrogen content in the matrix is that the mixture of kerosene, triethanolamine saturated hydroxyl and unsaturated hydroxyl is used in the carburizing process. A large amount of hydrogen is produced at high temperature. In addition, the tempering time at low temperature is not enough (the original tempering time is only 2 hours), while the component is large and the tempering time is too short, resulting in the high content of hydrogen remaining in the component matrix and the large positive stress Hydrogen embrittlement fracture is caused by force.

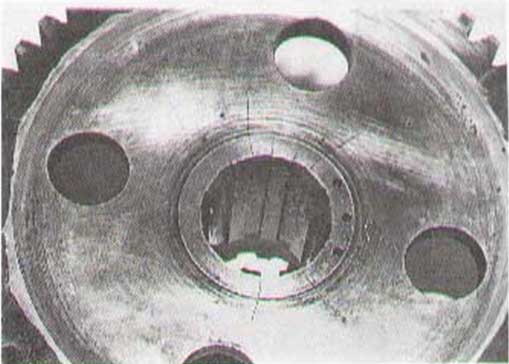

It can be observed that many cracks are radial along the bottom of the central spline shaft groove. According to the shape of the crack, the stress of the keyway is large. The bottom angle of the spline shaft groove is at a right angle.