Abstract

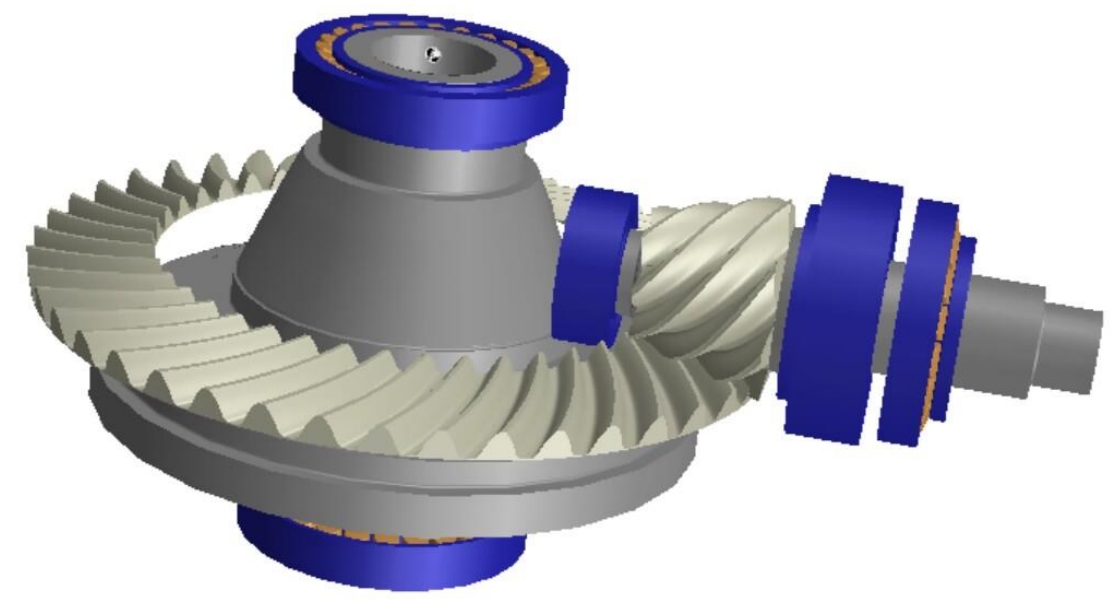

The spiral bevel gear transmission system is widely used in various fields such as aerospace, automobile, and shipbuilding due to its high transmission efficiency, strong bearing capacity, and compact structure. During power transmission, the loaded deformation of the transmission system leads to deviations in the meshing state of the gear pair, thereby affecting the transmission performance. Traditional analysis models, such as beam element models, offer fast computation but low accuracy, while full finite element models provide accurate results but are computationally intensive. Therefore, there is an urgent need for a method that combines both accuracy and efficiency.

This paper presents a finite element method to study the performance of the spiral bevel gear transmission system, addressing both analysis efficiency and calculation accuracy. The specific research work includes:

- Constructing Equivalent Mechanical Models: Equivalent methods for the mechanical models of various components of the transmission system are studied. The transmission shaft is equivalent to both a solid finite element model and a beam element model. The meshing contact effect of the gear pair is equivalent to meshing forces and a rigid disk containing meshing stiffness. The bearing support effect is equivalent to a stiffness matrix.

- Studying Meshing Misalignment: Based on the solid finite element coupling analysis model of the transmission shaft, the meshing misalignment of the transmission system is studied. A multi-tooth meshing analysis model is constructed using the tooth surface equation, and its loading contact analysis characteristics are studied based on meshing misalignment adjustments. Comparative analyses are conducted with beam element-based and full finite element models.

- Dynamic Characteristics Analysis: The multi-tooth meshing stiffness is solved based on the multi-tooth meshing model, and a dynamic model of the spiral bevel gear transmission system, including meshing stiffness, is constructed. Modal analysis is performed to obtain the inherent characteristics of the transmission system. Harmonic response analysis is used to solve the dynamic response of the transmission system under multi-tooth meshing force excitation.

- Experimental Verification: Testing experiments are conducted on a spiral bevel gear pair using a CNC rolling inspection machine. The loading marks and transmission errors of the system are obtained. Acceleration sensors are used to extract vibration signals during meshing, and software is employed to obtain the frequency characteristic curve of the system. The static and dynamic characteristics analysis results are compared with the experimental results to validate the proposed methods.

This research solves the problem of fast and accurate performance analysis of spiral bevel gear transmission systems and verifies the feasibility and accuracy of the static and dynamic characteristics analysis methods through testing experiments. It provides guidance for the adjustment design and theoretical analysis of spiral bevel gear transmission systems.

1. Source of the Project

This project is funded by the National Key Research and Development Program of China (“Demonstration and Application of Key Technologies for High-Performance Bevel Gear Transmission” (No. 2020YFB2010200)), the National Natural Science Foundation of China (“Research on Profile Design and Manufacturing Methods of Arcuate Bevel Gears for Vibration Control of High-Speed Transmission Systems” (No. 52275052)), and the General Program of Chongqing Natural Science Foundation (“Research on Design Theory and Efficient Machining Method of High-Performance Pure Rolling Contact Bevel Gears” (No. CSTB2022NSCQ-MSX0475)).

2. Research Background and Significance

Spiral bevel gear transmission systems play a crucial role in various industries due to their smooth transmission, high efficiency, strong bearing capacity, and compact structure. However, their complex geometric structure and meshing characteristics make them one of the most challenging gear transmission forms. Failures in gear transmission systems can severely impact production and economic benefits, potentially leading to significant safety risks. Therefore, it is imperative to deepen the research on the performance analysis of spiral bevel gear transmission systems. This research aims to minimize equipment downtime, safety accidents, and economic losses caused by gear transmission system failures through in-depth theoretical analysis, fault prediction, and performance optimization, thus ensuring the stable and efficient operation of various industries.

During actual operation, the meshing process between gear pairs generates meshing forces, which are transmitted to the bearings through the transmission shaft, causing a certain degree of elastic deformation in the entire transmission system. When these forces continuously act on the transmission system, the originally accurate gear installation positions will shift slightly due to the forces, resulting in a relative position change from the ideal meshing state, defined as the meshing misalignment of the gear pair. According to the principle of meshing misalignment, the deformation of the tooth surface meshing points or the transmission shaft can be used to calculate the meshing misalignment. Due to the considerable complexity and uncertainty in locating tooth surface meshing points, it is difficult to solve them directly through conventional observations. Therefore, it is more suitable to calculate using transmission shaft deformation.

Finite element methods (FEM) are employed to establish static models of spiral bevel gear transmission systems, including beam element models and solid element models. Beam element models offer fast computational speeds but large errors due to loaded deformation of the transmission shaft, affecting gear contact characteristics, transmission errors, and loaded indentation analysis. Solid element models improve calculation accuracy but require significant computational resources due to the large number and difficult division of meshes. Currently, there is a lack of efficient methods that balance calculation accuracy and efficiency for solving the meshing misalignment of spiral bevel gear transmission system models.

Dynamic model analysis methods for spiral bevel gear transmission systems primarily include the transfer matrix method, lumped mass method, and finite element method. The transfer matrix method segments the transmission system and constructs the entire system expression using transfer matrices. It has short computation times but low accuracy, prone to numerical instability and “missing roots.” The lumped mass method connects various parts of the transmission system using massless springs to form a system with multiple degrees of freedom. It provides fast analysis speeds but low accuracy and cannot obtain all system parameters. The finite element method conducts a complete three-dimensional model analysis of the system, providing accurate calculations but requiring significant computer resources, with calculation accuracy and speed largely depending on mesh division. At present, there is room for improvement in rapidly solving the dynamic characteristics of spiral bevel gear transmission system models using the finite element method.

3. Research Status

3.1 Research Status of Meshing Misalignment in Spiral Bevel Gear Transmission Systems

During power transmission, the internal deformation of spiral bevel gear transmission systems due to loading leads to offsets in the initial meshing positions of gear pairs, affecting the smoothness, noise level, wear rate, and overall transmission efficiency of gear pair transmissions. Therefore, rapidly and accurately analyzing the meshing misalignment of transmission systems is crucial for evaluating the loaded meshing performance of gear pairs and optimizing tooth surface design. Scholars have conducted relevant research on meshing misalignment analysis methods for transmission systems.

Litvin et al. considered installation misalignment and proposed a new analysis method for tooth surface contact characteristics of spiral bevel gears, studying their impact on transmission errors and loaded indentation. Qin et al. comprehensively considered errors during assembly, manufacturing, and loading processes to obtain the system’s meshing misalignment and adjusted the tooth surface design to study gear pair meshing performance, verifying the accuracy of the theoretical design method through gear fatigue tests. Gu et al. considered the effects of edge contact and installation misalignment of gear pairs and proposed a contact analysis method for arcuate bevel gear split transmission systems. Teik et al. considered the impact of assembly errors and used quasi-static analysis to study their influence on the meshing characteristics of hypoid gears in detail. Tang et al. derived the theoretical tooth surface equations for large and small wheels in arcuate bevel gears based on gear meshing principles, considering installation errors of gear pairs and studying their influence on the tooth surface contact state of arcuate bevel gears. Cai et al. considered the impact of installation misalignment and studied tooth surface redesign methods, utilizing multiple misalignment installation methods formed between tooth surfaces to establish trajectory functions to calculate installation misalignments and redesign gear tooth surfaces. Li et al. fully considered various errors during assembly and processing, used finite element analysis to construct finite element models of bevel gear pairs, and studied their comprehensive impact on meshing forces, transmission errors, and loaded indentation of gear pairs.

Lai et al. used Masta software to solve the meshing misalignment of gear pairs under real working conditions, obtained the influence of gear pair meshing characteristics through loaded contact analysis, and verified the simulation results through transmission test rig experiments. Yang et al. proposed an analysis method for the meshing performance of hypoid gear pairs, constructed transmission system models using Masta software, extracted transmission system deformations, calculated system misalignments, and studied the influence of gear meshing performance under conditions of independent and comprehensive misalignments. Yan et al. used Romax software to construct transmission models, extracted the meshing misalignment of the main reduction gear, and studied the influence of different housing models on meshing misalignment. Simon et al. employed advanced tooth surface contact analysis methods, considering machine tool position accuracy and misalignment of mating parts, to study their impact on transmission errors in non-matching arcuate bevel gear transmissions.

Li et al. proposed an innovative finite element modeling method, considering the stiffness coupling characteristics and nonlinearity of bearings, to construct a complete finite element model of the drive axle transmission system, solve the system’s meshing misalignment, and conduct comparative analysis through drive axle support rigidity tests. Gao et al. considered the support deformation of the housing, transmission shaft, and bearings under load, superimposed the deformations to calculate the equivalent misalignment of the gear pair, and constructed a tooth contact model considering misalignment to obtain the contact indentation. Qi calculated the stiffness matrices of the shaft, bearings, and gears based on Euler beam theory and deformation equations, obtained the system’s coupling matrix through superposition, and calculated the meshing misalignment using the force balance equation to study the contact analysis method of gear pairs. Zhou et al. considered the influence of shaft and bearing deformations on meshing misalignment, constructed gear transmission system models, and studied the impact of meshing misalignment on system reliability. He et al. studied the influence of elastic deformation of gears under load on the housing, considering the housing’s stiffness and mass matrices, and calculated the resulting meshing misalignment.

In summary, existing meshing misalignment analysis methods for spiral bevel gear transmission systems mostly simplify the transmission shaft as a beam element model. However, this simplification ignores the assumptions of Euler beam and Timoshenko beam theories. When the transmission shaft structure is complex, the deformation analysis results may have large errors, leading to inaccurate calculations of the meshing misalignment of the gear transmission system. Alternatively, constructing a full solid finite element model can provide better calculation results but is extremely resource-intensive. Obtaining meshing misalignment through experiments is even more challenging. Therefore, there is an urgent need for a fast and accurate meshing misalignment analysis method for spiral bevel gear transmission systems to address the current issues.

3.2 Research Status of Dynamic Analysis of Spiral Bevel Gear Transmission Systems

Dynamic analysis can more accurately assess and improve the efficiency, bearing capacity, and service life of gear transmissions, aiding in the design of transmission systems with better performance and higher reliability. Scholars have conducted relevant research on dynamic analysis methods for transmission systems. Li et al. constructed coupled models of axial, lateral, and torsional vibration modes for spiral bevel gear rotor-bearing systems, studying the vibration mechanism of spiral bevel gear rotor systems. Hua et al. considered the elasticity of bearings, using the finite element method to construct a cone gear rotor-bearing dynamics model and studying its impact on the vibration characteristics of the entire transmission system. Yang et al. considered the influence of elastic housing structures, treating gear pairs, bearings, and housings as dynamic substructures, and equivalenting small and large gear models as rigid bodies with nonlinear and time-varying meshing coupling, proposing a method to predict the dynamic response of hypoid gearboxes under complex working conditions. Li et al. considered oil film force bearing support and used numerical analysis to study the nonlinear dynamic behavior of cone gear transmission systems. Yavuz et al. proposed a dynamics model that includes the finite element model of the transmission shaft, mutually coupled with the meshing model of the gear pair, and the nonlinearity of meshing stiffness and backlash, studying the diverse nonlinear time-varying dynamic characteristics of spiral bevel gear transmission systems. Li et al. constructed an 8-degree-of-freedom nonlinear dynamics model of a spiral bevel gear pair, including the influences of transmission errors, time-varying meshing stiffness, and asymmetric meshing stiffness, using numerical analysis to study the vibration characteristics of spiral bevel gear transmission systems under asymmetric meshing stiffness conditions. Hua et al. based their research on the influence of pinion installation methods, using the finite element method to construct a dynamics model of the gear-bearing structure and studying the impact of different design configurations on the dynamic characteristics of arcuate bevel gears. Shi et al. considered the connection between the propeller shaft and pinion shaft using a universal joint, proposing an improved dynamics model for hypoid gear rotor systems, considering shaft misalignment and pinion mass imbalance, and studying the dynamic response laws of hypoid gears. Zhu et al. considered the intermediate and tail gearboxes and the laminated coupling of the spiral bevel gear tail shaft in helicopters, combining the finite element and lumped mass methods to establish dynamics models. Under the influence of time-varying meshing stiffness and external unbalanced excitation, they studied the impact of laminated membrane couplings, tail rotor excitation, and tail shaft length on the dynamic characteristics of spiral bevel gear systems. Cheng et al. constructed a generalized 3D dynamics model, considering load transfer errors as important excitation sources, and studied the coupled translational-rotational vibration response of hypoid gear rotor systems.

Liu et al. proposed adding virtual supports to arcuate bevel gear rotor systems to ensure meshing stability, using the transfer matrix method to construct vibration models of arcuate bevel gear-rotor systems and analyzing their dynamic characteristics. Wang et al. based their research on the lumped parameter method, considering the elastic deformation of transmission shafts and bearings, and constructed multi-degree-of-freedom coupled vibration dynamics models for arcuate bevel gears, including bending, torsion, axial, and yawing. Wang et al. constructed a dynamics model of an arcuate bevel gear rotor-bearing system considering elastic support, studying the system’s nonlinear vibration characteristics. Yu et al. constructed a longitudinal-bending-torsional coupling dynamics model for cone gear transmission rotor-bearing systems, considering the influence of external loads on system stiffness and damping coefficients, as well as the system’s modes. Lin et al. considered arcuate bevel gears and planetary gear trains in helicopters, constructing a pure torsional vibration dynamics model and using the lumped parameter method to establish dynamics equations incorporating backlash. Under the excitation of time-varying meshing stiffness, backlash, and external loads, they studied the system’s dynamic load characteristics. Xie et al. used Adams to construct a dynamics analysis model of a double-stage arcuate bevel gear in a nutation reducer and studied its dynamic characteristics. Xiong et al. used Adams software to construct a dynamics simulation model including ball bearings and spiral bevel gears, using variable speed as the system excitation to study its dynamic response under these conditions. Yao et al. proposed a new dynamics analysis method for ball bearing and spiral bevel gear transmissions based on arcuate bevel gear contact dynamics, studying the system’s dynamic response characteristics under the influence of preload and load torque. Feng et al. used the lumped parameter method to construct a nonlinear dynamics model with multiple degrees of freedom, including the prime mover, load, and gear pair, for spiral bevel gear systems, solving the system’s dynamic response under the influences of time-varying meshing stiffness, friction, gyroscopic effects, etc. Cheng et al. considered the effects of time-varying meshing stiffness, transmission errors, and backlash, constructing a coupled dynamics model of an arcuate bevel gear transmission system with 16 degrees of freedom in bending, torsion, and axial directions, and solving the system’s response. Liao et al. ued the finite element node method to construct a coupled dynamics model of an arcuate bevel gear transmission system with flexible shaft sections and bending, torsion, axial, and yawing degrees of freedom, studying the vibration characteristics of the transmission system dynamics under the influence of load torques and contact trajectories. Zeng et al. used Adams to construct a dynamics model of an arcuate bevel gear transmission system and solve the dynamic characteristics curves of rotational speed and meshing forces of gear teeth. Feng et al. constructed an 8-degree-of-freedom dynamics model of an arcuate bevel gear and rotor transmission system, using a specific function in Matlab software to solve the system’s vibration response with and without crack influences. Yang et al. constructed a dynamics contact analysis model for a hypoid gearbox transmission system, solving the system’s dynamic response under the influences of meshing deformation, bending deformation of the transmission shaft, and bearing support stiffness.

In summary, common dynamics models for spiral bevel gear transmission systems include the lumped mass method, transfer matrix method, and finite element method, each with its advantages and limitations. However, scholars have less experience combining the lumped parameter method with the finite element method to establish dynamics models. Using the lumped parameter method to handle global dynamics characteristics and the finite element method to refine complex local structures can ensure both computational efficiency and accurate reflection of system dynamic characteristics. Existing dynamics analysis methods provide theoretical support and methodological references for hybrid modeling approaches.

3.3 Research Status of Gear Transmission System Test Rigs

Gear transmission system test rigs are precise experimental facilities primarily used for comprehensive and multi-level performance testing and in-depth dynamic characteristic analysis of various gear transmission devices. Scholars attach great importance to research on gear transmission system test rigs, not only focusing on improving the test rigs’ testing accuracy and adaptability but also conducting extensive work on test methods, data analysis, model establishment, and fault diagnosis techniques. Hargreaves et al. explored the specific impact of different types and properties of lubricating oils on gear transmission system efficiency, constructing a mechanical test rig. Bader built a unique oscillating box gear test rig to deeply study the dynamic characteristics and performance parameters of gear transmission systems. This test rig connects two identical gearboxes using universal joint couplings, with one gearbox designed to rotate freely around a fixed axis to achieve torque loading.

Furthermore, researchers like Wang and his team have developed an advanced closed-loop gear transmission system test rig, incorporating features such as adjustable speed, variable load, and high-precision measurement capabilities. This rig enables the simulation of various operating conditions, facilitating the investigation of gear wear, fatigue, and vibration characteristics under diverse loads and speeds. The integration of sensors and data acquisition systems allows for real-time monitoring and analysis, enhancing the understanding of gear system behavior.

In the realm of model establishment and simulation, Chen et al. proposed a hybrid modeling approach combining finite element analysis (FEA) with multi-body dynamics (MBD) to predict the dynamic responses of gear transmission systems accurately. This method aids in optimizing the design of gear components and reducing noise and vibration levels. Additionally, the application of artificial intelligence (AI) and machine learning (ML) algorithms has gained momentum in fault diagnosis and condition monitoring of gear systems. For instance, Liu et al. utilized deep learning techniques to develop a predictive maintenance framework that effectively identifies early signs of gear failure based on vibration signals collected from test rigs.

Moreover, environmental and energy efficiency considerations have prompted research into alternative lubrication methods and the impact of temperature variations on gear performance. Research by Patel et al. investigated the use of biodegradable lubricants in gear transmission systems, assessing their tribological performance and environmental footprint on the test rig. Similarly, studies by Zhang et al. focused on the influence of temperature on gear mesh stiffness and system efficiency, employing thermally controlled test rigs to simulate realistic operating temperatures.

Overall, the research status of gear transmission system test rigs is characterized by a continuous drive towards enhancing testing precision, expanding the scope of analysis, and integrating advanced technologies such as AI and ML for improved fault detection and system optimization. These advancements not only contribute to the development of more reliable and efficient gear transmission systems but also align with broader industry trends towards sustainability and environmental responsibility.