1. Introduction

1.1 Background and Significance

The accessory drive system is an essential power output component of an aeroengine, and spiral bevel gears are crucial parts within this system. In special oil – depleted conditions such as when the gearbox is damaged or the lubrication system fails, the temperature at the meshing contact of spiral bevel gears rises rapidly, which can lead to gear failure. The quality of the tooth surface, which is significantly influenced by the final grinding process, plays a vital role in determining the flash temperature caused by dry friction. Therefore, studying the micro – morphology of ground tooth surfaces and the flash temperature under oil – depleted conditions is of great importance for ensuring the safe operation of aircraft.

1.2 Research Objectives

The main goal of this research is to establish a three – dimensional solid model of spiral bevel gears considering the surface morphology after grinding and to analyze the relationship between the grinding wheel morphology, gear morphology, and tooth surface flash temperature. This involves simulating the grinding wheel surface based on fractal theory, deriving the motion trajectory of abrasive grains, and conducting finite – element simulations to calculate the flash temperature.

2. Grinding Wheel Surface Topography Modeling

2.1 Fractal Theory Overview

Fractal theory, proposed by Mandelbrot, provides a mathematical way to describe complex and random shapes. In this study, the Weierstras – Mandelbrot fractal function is used to model the three – dimensional surface topography of the grinding wheel. The structure function method is employed to calculate the fractal dimension and fractal roughness parameters from the measured 砂轮 surface data.

2.2 Fractal Parameter Calculation

The structure function \(S(\tau)\) is related to the 砂轮 surface height function \(Z(x)\) by the equation: \(S(\tau)=\left<[z(x+\tau)-z(x)]^{2}\right>=C \tau^{\left(4 – 2 D_{z}\right)}\) where \(D_{z}\) is the fractal dimension of the 砂轮 surface profile, and C is a proportionality coefficient. By taking the logarithm of both sides, the fractal dimension and fractal roughness parameters can be determined from the slope and intercept of the resulting linear relationship.

2.3 Simulation of Grinding Wheel Surface Topography

Using the derived fractal function and the calculated parameters, the three – dimensional surface topography of the 砂轮 is simulated. The influence of different grinding wheel grit sizes on the surface morphology is analyzed. As shown in Table 1, larger grit sizes result in higher fractal dimensions and lower fractal roughness parameters, indicating a smoother surface.

| Grit Size | Fractal Dimension (\(D_{z}\)) | Fractal Roughness (G) |

|---|---|---|

| SG46 M/# | 1.2747 | 4.3842e – 5 |

| SG60 M/# | 1.2909 | 3.9039e – 5 |

| SG80 M/# | 1.3068 | 3.4631e – 5 |

| SG120 M/# | 1.3272 | 2.9030e – 5 |

| SG180 M/# | 1.3503 | 2.4262e – 5 |

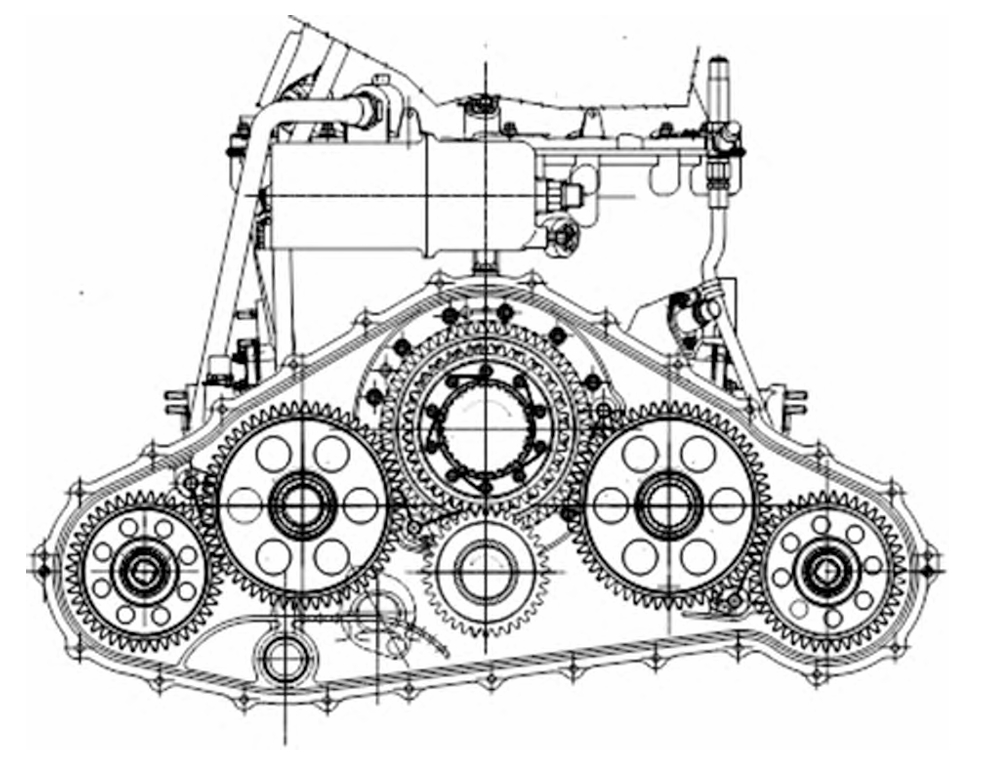

Figure 1: Simulated Surface Topography of Grinding Wheels with Different Grit Sizes

3. Spiral Bevel Gear Grinding Surface Morphology Simulation

3.1 Grinding Process Kinematics

The grinding process of spiral bevel gears involves complex kinematic relationships. The motion trajectory of abrasive grains on the grinding wheel is derived considering the vibration caused by wheel imbalance. The tooth surface is projected onto an axial section, and both the tooth and 砂轮 surfaces are discretized to simulate the tooth surface morphology under different grinding parameters.

3.2 Tooth Surface Modeling

The mathematical models for the tooth surfaces of both the pinion and gear are established based on the grinding kinematics. The influence of vibration on the motion trajectory of abrasive grains is incorporated into the model. The resulting tooth surface morphology is simulated using MATLAB and visualized in SolidWorks.

3.3 Effect of Grinding Parameters

The effects of grinding parameters such as depth of cut, 砂轮 speed, grit size, and 展成速度 on the tooth surface morphology are analyzed. Table 2 summarizes the orthogonal experiment results, showing that the depth of cut has the most significant impact on surface roughness, followed by grit size, 砂轮 speed, and 展成速度.

| Parameter | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Depth of Cut (mm) | 0.02 | 0.05 | 0.08 | 0.11 |

| Grinding Wheel Speed (m/s) | 16.5 | 26.5 | 35.2 | 52.2 |

| Grit Size (M/#) | 46 | 60 | 80 | 120 |

| 展成速度 (m/min) | 2.7 | 3.6 | 4.4 | 7.2 |

Figure 2: Simulated Tooth Surface Morphology under Different Grinding Parameters

4. Experimental Analysis of Grinding Surface Morphology

4.1 Experimental Setup

The experiments are conducted using a Gleason Phoenix 600G CNC 磨齿机 with SG 砂轮. The 齿轮 material is 20CrMnTi with a hardness of 58 – 62 HRC. The tooth surface morphology is measured using a Taylor Map CCI 三维非接触式光学轮廓仪.

4.2 Measurement and Comparison

The measured tooth surface morphology is compared with the simulated results. Table 3 shows the roughness values and relative errors under different parameters. The relative error is found to be within 5%, validating the accuracy of the simulation method.

| Parameter Combination | Experimental Ra (μm) | Simulated Ra (μm) | Relative Error |

|---|---|---|---|

| 0.02, 16.5, 46, 2.7 | 0.431 | 0.411 | – 4.64% |

| 0.02, 26.5, 60, 3.6 | 0.412 | 0.392 | – 4.85% |

| 0.02, 35.2, 80, 4.4 | 0.304 | 0.294 | – 3.29% |

| 0.02, 52.2, 120, 7.2 | 0.314 | 0.304 | – 3.18% |

Figure 3: Comparison of Measured and Simulated Tooth Surface Morphology

4.3 Optimization of Grinding Parameters

Using orthogonal experiments and range analysis, the optimal grinding parameters are determined. The optimal configuration is a depth of cut of 0.02 mm, 砂轮 speed of 52.5 m/s, grit size of 80 M/#, and 展成速度 of 4.4 m/min. The regression equation for surface roughness is also established: \(R_{a}=1.360021 \cdot a^{4.385} \cdot V_{s}^{-0.001119} \cdot M^{-0.000479} \cdot V_{w}^{0.00565}\)

5. Tooth Surface Flash Temperature Calculation

5.1 Theoretical Model

The flash temperature is calculated by considering the frictional heat generated at the micro – asperity contacts. The total heat generated is given by: \(Q = f \times F_{N} \times v_{t}\) where f is the friction coefficient, \(F_{N}\) is the normal force, and \(v_{t}\) is the relative sliding 速度. The normal force is determined using finite – element analysis, and the sliding 速度 is calculated based on the kinematics of the gear meshing.

5.2 Finite – Element Simulation

The three – dimensional solid model of the 齿轮 is imported into ANSYS, and the Coupled Field Transient module is used to simulate the frictional heat generation. The heat flux and convection coefficients are applied as boundary conditions. The simulation results show that the maximum flash temperature occurs near the tooth root for the gear and near the tooth tip for the pinion.

Figure 4: Finite – Element Simulation Results of Tooth Surface Temperature Distribution

5.3 Comparison of Results

The simulated flash temperature results are compared with the theoretical calculations. Table 4 shows that the maximum flash temperature from the simulation is slightly higher than the theoretical value, but the trends are consistent, validating the simulation method.

| Location | Theoretical Maximum Temperature (°C) | Simulated Maximum Temperature (°C) |

|---|---|---|

| Tooth Tip | 95 | 97 |

| Tooth Root | 118 | 121 |

Figure 5: Comparison of Theoretical and Simulated Flash Temperature Profiles

6. Conclusion

This research successfully establishes a comprehensive model for the micro – morphology of spiral bevel gear tooth surfaces after grinding and accurately calculates the flash temperature under oil – depleted conditions. The key findings include:

- The fractal theory – based method effectively models the 砂轮 surface topography, and the simulation results match well with the experimental measurements.

- The grinding parameters significantly affect the tooth surface morphology, and the optimal parameters are determined through orthogonal experiments.

- The finite – element simulation accurately predicts the flash temperature distribution, providing valuable insights into the gear failure mechanisms under oil – depleted conditions.

Further research can focus on improving the accuracy of the model by considering additional factors such as material plasticity and thermal effects. This study contributes to the development of more reliable and durable spiral bevel gears for aerospace applications.