1. Introduction

Planetary gear systems play a crucial role in various mechanical applications due to their compact structure, high transmission ratio, efficiency, and strong load-carrying capacity. However, manufacturing errors during the production of gears and planet carriers can lead to increased vibration and noise, affecting the safety and reliability of the entire system. Among these errors, the position error of the pin shaft is an important factor that can cause gear position offsets and subsequent changes in internal incentives. This paper focuses on analyzing the dynamic characteristics of planetary gear systems under pin shaft position errors.

1.1 Research Background

In recent years, many studies have been conducted on gear meshing errors and their effects on dynamic characteristics. Some researchers have introduced mathematical models of tooth profile deviations to construct elastic dynamic equilibrium models considering factors such as tooth profile deviations, time-varying meshing stiffness, and backlash. Others have comprehensively considered various deformation factors to establish general gear meshing analysis models and revealed the influence mechanism of gear body structure coupling effects on total meshing stiffness. For the case of multiple manufacturing errors combined, some studies have decomposed three-dimensional shape deviations caused by machining errors into pitch errors, profile errors, and helix errors and explored the impact of machining errors on the continuous meshing process using the contact finite element method. In the field of gear nonlinear dynamics, researchers have established dynamic models considering machining errors, periodic time-varying stiffness, and nonlinear backlash to study problems such as the prediction of planetary gear modulation sidebands.

1.2 Research Objectives

This paper aims to analyze the influence of pin shaft position errors on the internal incentives of planetary gear systems, including meshing errors, time-varying meshing stiffness, and backlash. By constructing a dynamic model of the planetary gear transmission system and introducing error-induced incentives, the paper investigates the influence laws and mechanisms of pin position error phases on the dynamic responses of internal and external gear pairs and the load sharing characteristics of the planetary gear train. The research results can provide a theoretical reference for the low-noise design, machining, and assembly of herringbone planetary gear systems.

2. Analysis of Internal Incentives under Position Error

2.1 Meshing Error

When there is a position error of the pin shaft of the planetary wheel, the installation position of the planetary wheel changes, resulting in an error in the center distance between gears. This, in turn, causes periodic meshing errors between the planetary wheel and the sun wheel as well as the inner ring gear. The meshing errors of the gear pairs along the meshing line direction can be expressed as follows:

For the sun wheel-planetary wheel:

For the inner ring gear-planetary wheel:

where and are the end face pressure angles, is the position angle of the planetary wheel, is the center distance between the sun wheel and the planetary wheel, is the center distance after including the position error, and is the installation error value. As shown in Figure 2, the meshing errors of each group of sun wheel-planetary wheel and inner ring gear-planetary wheel along the meshing line direction change with the position error phase. The meshing error caused by the position error varies with the error phase, and there is a phase difference in the meshing errors of each gear pair due to the different position angles of the planetary wheel.

2.2 Time-Varying Meshing Stiffness

The vertical meshing line error of the gear pair caused by the pin shaft position error directly affects the position of the tooth meshing point and the time-varying meshing stiffness of the gear. Due to the existence of the position error of the planet carrier pin shaft, there is a center distance error between the planetary wheel and the sun wheel as well as the inner ring gear. The change in the center distance affects the contact ratio, pressure angle, and meshing point of the gear pair, thereby changing the gear meshing stiffness. Taking the external meshing helical gear pair end face spur gear pair as an example, when there is a center distance error, the meshing process is shown in Figure 3. The center distance error of the sun wheel-planetary wheel and the inner ring gear-planetary wheel can be determined as follows:

With the increase in the center distance of the gear pair, the base circle, addendum circle, and dedendum circle of the gear remain unchanged, but the meshing line of the gear pair changes from the original tangent of the pitch circle to a new tangent of the pitch circle, and the pitch circle radius and pressure angle also change. According to the geometric relationship of each parameter in the gear pair, the size of each line segment on the theoretical meshing line on the new base circle tangent can be calculated, and then the end face contact ratio and the axial contact ratio of the helical gear pair after including the position error can be obtained. Further, by analyzing the influence of the center distance change on the helical gear meshing and calculating the time-varying meshing stiffness of the helical gear with different center distance errors using the potential energy method, it is found that as the center distance error increases, the meshing surface of the helical gear decreases, the single-tooth meshing stiffness decreases, and the meshing cycle of a single tooth also decreases. Finally, the time-varying meshing stiffness of the gear pair is obtained by superimposing the single-tooth stiffness at intervals of the tooth pitch angle.

2.3 Backlash

After the gear pair changes the center distance under the position error, the deviation of the tooth meshing point also causes a change in the backlash. The change in the backlash of the straight gear along the meshing line direction caused by the center distance error is . The changes in the backlash of the sun wheel-planetary wheel and the inner ring gear-planetary wheel can be calculated as follows:

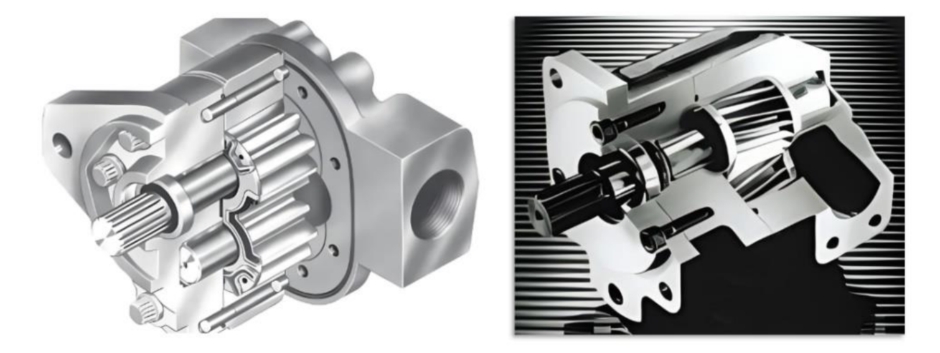

3. Planetary Gear Train Dynamic Model

To explore the influence of the planetary wheel position on the dynamic characteristics of the planetary transmission system, a dynamic model of a bent-torsion herringbone planetary gear train including a relief groove and backlash is established as shown in Figure 7. The model considers various factors such as the support stiffness and damping of each gear, the meshing stiffness and damping of each gear pair, and the elastic meshing force and viscous meshing force of each meshing pair. The dynamic differential equations of the sun wheel, planetary wheel, and inner ring gear are established according to Newton’s second law of motion. For example, the dynamic differential equations of the sun wheel are:

4. System Dynamic Characteristics Analysis

4.1 Influence of Position Error on Dynamic Load

Based on the dynamic model of the planetary gear train with position errors, the dynamic responses of the gear pairs with errors are analyzed. By setting the input rotational speed to 3000 r/min, the pin shaft position error of the planetary wheel 1 to 40 μm with error phases of 0 and , and the initial backlash of each internal and external meshing pair to 20 μm, the error excitation parameters and dynamic meshing forces of the internal and external meshing pairs of the planetary wheel 1 in different states are obtained as shown in Tables 1 – 2 and Figures 8 – 9. When , the backlash of the external meshing pair increases, and the positive meshing error reduces the dynamic transfer error (DTE), while for the internal meshing pair, the backlash decreases, and the negative meshing error increases the DTE, resulting in a bilateral impact on the internal meshing pair of the planetary wheel 1. When , the situation is reversed. By comparing the response results when the pin shaft position error of the planetary wheel 1 is 20 μm with error phases of and , it is found that when , the backlash changes of the internal and external meshing pairs are very small, and both produce positive meshing errors, resulting in lower internal and external meshing forces and more parts where the teeth are disengaged. When , the backlash changes are also small, but both produce negative meshing errors, resulting in significantly higher internal and external meshing forces.

4.2 Influence of Position Error on Load Sharing Characteristics

After clarifying the influence mechanism of the position error on the gear pair meshing, the influence of the position error of the planet carrier pin shaft on the planetary transmission system is further analyzed. The load distribution characteristics in each transmission link are analyzed by considering the differences in the dynamic transfer errors and meshing forces of each gear pair, and the load sharing coefficient is used for characterization. The load sharing coefficient is defined as the ratio of the meshing force of each gear pair to the average meshing force at a certain moment. By analyzing the change law of the load sharing coefficient of each internal and external meshing pair on the left side of the planetary gear train with respect to the position error phase of the planetary wheel 1, it is found that the load sharing coefficients of each internal and external meshing pair change with the position error phase of the planetary wheel 1. When the error phase is 0 and , the load sharing coefficients of the internal and external meshing pairs are the smallest, and when the error phase is and , the load sharing coefficients reach the maximum value.

5. Conclusions

- For the position error of the planetary wheel pin shaft, the influence mechanisms on the meshing error, center distance, time-varying meshing stiffness, and backlash of the internal and external meshing pairs of the planetary wheel are fully considered, and the changes in various internal incentives caused by the position error are clarified.

- A dynamic model of the planetary gear transmission system is established, and various incentives caused by the position error are introduced into the system. The model comprehensively considers factors such as the backlash, meshing error, time-varying meshing stiffness affected by errors, and the relief groove of each herringbone gear, coupling the influence of the position error more comprehensively.

- Under the combined influence of the pin shaft position error and the planetary wheel position angle, the decrease in the backlash of the meshing pair and the negative meshing error can lead to a surge in the meshing force, even bilateral impacts, reducing the load sharing performance of the system. Conversely, the increase in the backlash of the meshing pair and the positive meshing error can reduce the meshing force, and the influence on the load sharing performance of the system is relatively weak.