The bending fatigue of hypoid gear root of drive axle is affected by many parameters, including the geometry of hypoid gear root area, load distribution along the tooth surface, tooth surface polishing, material properties, residual stress and working conditions (speed, installation deviation, dynamic load, etc.). It is mainly divided into two categories: the first category directly affects the tooth root stress distribution, such as the tool edge profile, which directly determines the tooth root shape of hypoid gears, and then affects the bending fatigue strength. In the second category, the tooth root stress is indirectly affected by changing the load distribution and contact mode along the tooth blank, such as the installation deviation of hypoid gear (defined as the offset between the installation position of gear pair and the ideal installation position), which indirectly affects the bending fatigue strength. Therefore, before predicting the bending fatigue of hypoid gears, it is necessary to analyze the stress state at the root of hypoid gears.

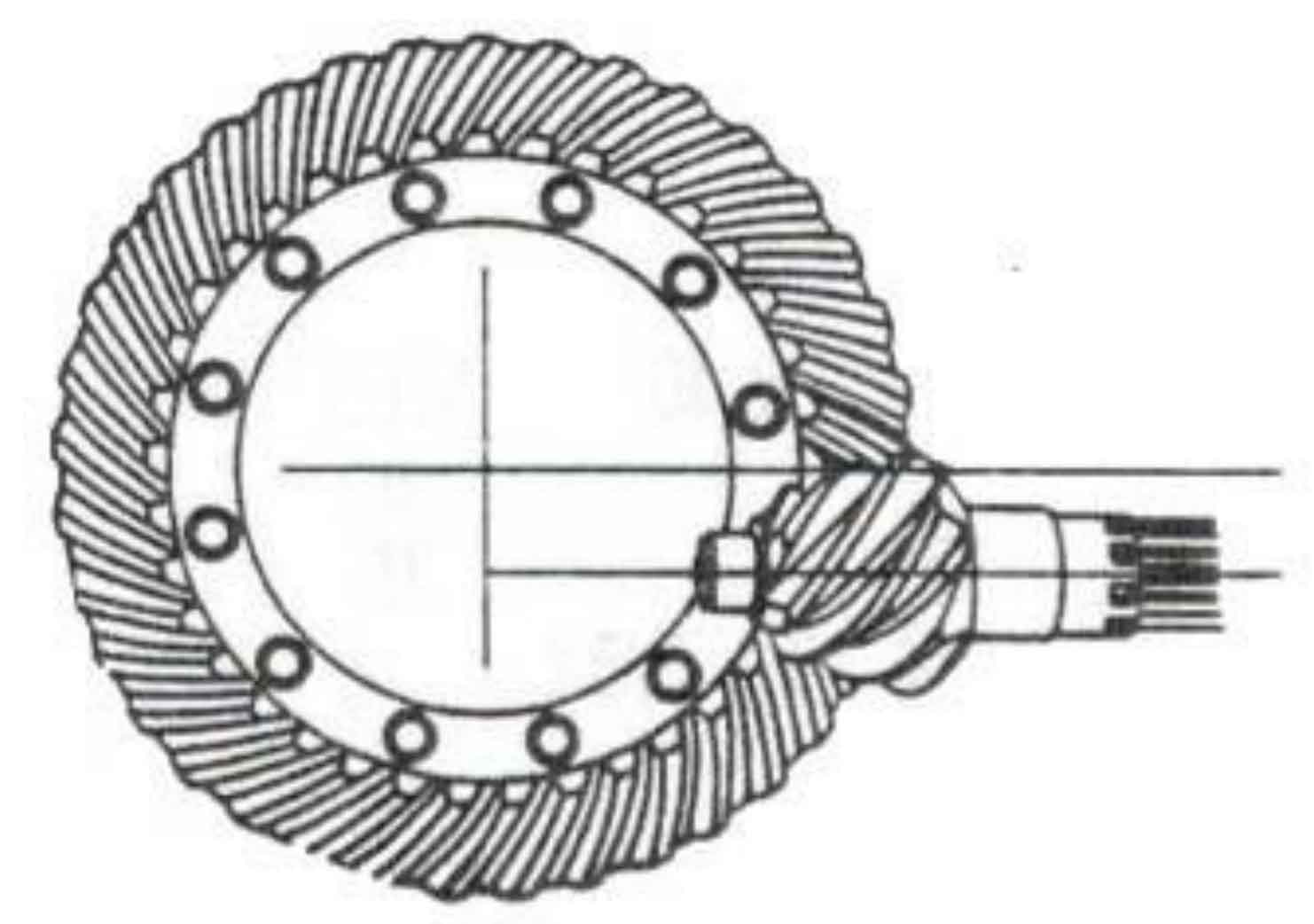

It is a relatively complex task to accurately predict the stress state at the root of the hypoid gear of the drive axle, which has been studied by many scholars. It can be seen from the comparative analysis that the current research mainly analyzes the single spiral bevel gear or hypoid gear pair, without considering the deformation of the gear support shell. For the drive axle hypoid gear, the stress state at the tooth root will be affected by the flexible deformation of the support shell and the deformation of the support bearing. Therefore, this chapter will establish a prediction method based on the tooth root stress and bending fatigue life of the hypoid gear of the integral drive axle, and verify the prediction results through the bench test.

Firstly, the abaqus/standard static general solver is used to simulate the nonlinear meshing process of multi tooth contact of hypoid gear in automotive drive axle, and the stress variation law of gear root is obtained. In the state of drive axle assembly, the tooth root stress corresponding to the static meshing of hypoid gear is measured, and the numerical simulation results are compared with the experimental results. Secondly, the influence of different types of installation deviation on the bending stress of hypoid tooth root is analyzed and compared. Thirdly, the bending fatigue prediction model of hypoid gear is established according to the finite element calculation results. Finally, the influence of the installation deviation of hypoid gear on the fatigue of hypoid gear is compared and analyzed.