In the actual use of hypoid gears, the wear phenomenon can be regarded as tooth profile error. In order to facilitate the construction of digital real hypoid gear tooth surface, the real tooth surface mathematical model of hypoid gear is established here.

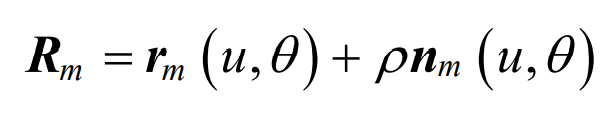

In the measuring coordinate system SM, the position vector of the measuring probe center on the theoretical hypoid gear tooth surface Σ G is expressed as:

Where, RM and nm are respectively the position vector and normal vector of the point on the tooth surface of the theoretical hypoid gear in the measuring coordinate system SM; ρ Is the probe radius.

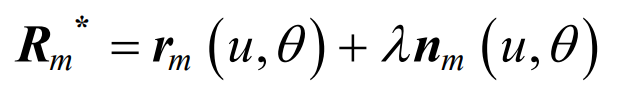

In the measuring coordinate system SM, the position vector of the measuring probe center on the real hypoid gear tooth surface Σ R is expressed as:

Where, λ To measure the offset between the actual position of the probe center and the theoretical hypoid gear tooth surface Σ G.