1. Introduction

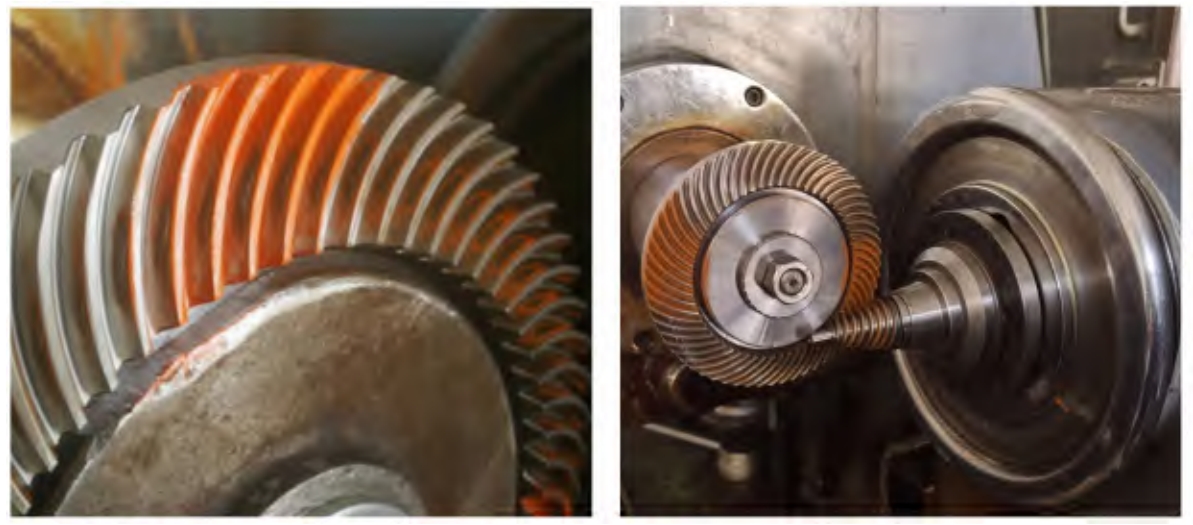

Bevel gears play a critical role in mechanical transmission systems, particularly in aerospace, automotive, and industrial applications. Their performance heavily depends on the quality of their tooth surfaces, which must meet stringent precision requirements to ensure smooth operation and minimize wear. Traditional methods for evaluating bevel gear tooth surfaces often rely on complex mathematical models derived from design and machine adjustment parameters. However, these models are challenging to construct in real-world scenarios due to the unavailability of precise . This paper introduces a novel relative evaluation method that circumvents the need for theoretical models by using a high-quality reference gear from the same production batch as a . The approach leverages optical measurement technology to capture comprehensive ,enabling direct comparison between the reference and gears.

2. Methodology

2.1 Relative Evaluation Principle

The idea of the relative evaluation method is to use a high-quality gear from the same production batch as a reference. The reference gear’s tooth surface is treated as the ,and deviations from this are measured for other gears in the batch.

3. Experimental Setup

| Parameter | Value |

|---|---|

| Number of Teeth | 9 |

| Module | 3.877 mm |

| Helix Angle | 46.50° |

| Pitch Cone Angle | 13.0086°, 18.0078°, 12.0069° |

4. Conclusion

The relative evaluation method presented in this paper offers a practical solution for assessing bevel gear tooth surface quality without relying on complex theoretical models. By using a reference gear from the same production batch and leveraging optical measurement technology, the approach provides accurate and efficient results while reflecting process stability. Future work will focus on expanding the method to cover full tooth width measurements and refining evaluation criteria for enhanced industrial applicability.