This paper takes the self-designed new type of bevel gear-roller flat plate continuously variable transmission (CVT) as an example to conduct theoretical research on the slip rate, power loss, and friction efficiency in the transmission process, and uses ANSYS software to simulate and analyze the temperature field of friction heat generation of the roller flat plate. The results show that with the increase of rotational speed, the temperature of the roller and the flat plate rises; with the increase of the compression force, the friction power loss increases, and the friction efficiency decreases. The increase of the compression force will increase the sliding speed, resulting in more frictional heat, and at the same time, it will also increase the contact area, making the area of frictional heat larger, thus having a more obvious impact on the temperature rise. The new type of bevel gear-roller flat plate CVT has a high friction efficiency, and its frictional temperature rise is also relatively small.

I. Introduction

The CVT has the advantages of a simple structure, convenient operation, high transmission efficiency, good constant power characteristics, and low noise, which can effectively improve the fuel economy of automobiles and achieve the purpose of energy conservation and emission reduction. Therefore, CVTs have received more and more attention and adoption in the industry. At present, domestic and foreign scholars have done a lot of research on the structure, materials, transmission characteristics, and control strategies of CVTs. However, there are relatively few studies on the friction heat generation and temperature field of friction-type CVTs. The authors of this paper study the friction efficiency and temperature field of the self-designed new type of bevel gear-roller flat plate CVT to verify the feasibility of the design and provide a reference for the future research of CVTs.

II. Structure and Transmission Principle of the New CVT

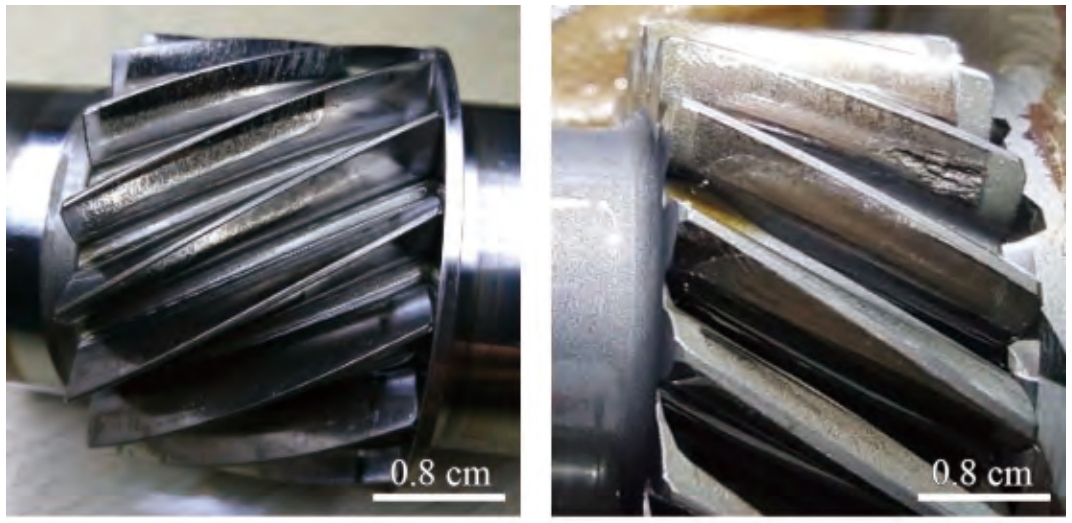

The new type of bevel gear-roller flat plate CVT is based on the transmission principle of the roller flat plate CVT, using the characteristics of bevel gear transmission, and adopting the way of input power diversion and confluence output to achieve the friction contact of four points between the roller and the flat plate, thereby improving the transmission capacity. The principle is shown in Figure 1.

The design adopts a symmetrical structure. The bevel gears 3 and 4 are symmetrical about the input and output axes. The bevel gears 5 and 6 are symmetrical about the axis, and the rollers 7 and 8 are symmetrical about the axis. The flat friction wheels 9 and 10 are symmetrical about the axis. It is equivalent to that the flat friction wheels 9 and 10 sandwich the rollers 7 and 8 in the middle. The friction wheels 9 and 10 are coaxially fixed with the bevel gears 3 and 4 and rotate together. The rollers 7 and 8 are connected with the bevel gears 5 and 6 by guide keys and can make axial movement within a certain range along their axes. The gear shaft 1 meshes with the bevel gears 3 and 4 on both sides respectively, and the gear shaft 2 meshes with the bevel gears 5 and 6 at the same time, with a symmetrical arrangement.

Power is transmitted to the input gear shaft 1 through the input shaft, and then is diverted and transmitted to the bevel gears 3 and 4 through the meshing transmission of the bevel gears. On the small end face side of the bevel gears 3 and 4, there are fixed flat plates 9 and 10, which rotate in the same direction as the bevel gears 3 and 4. The rollers 7 and 8 are respectively pressed on the flat plates 9 and 10 to form friction transmission, and the power is transmitted to the bevel gears 5 and 6 through the rollers 7 and 8, and then is confluence transmitted to the bevel gear 2 for output. The rollers 7 and 8 can respectively move along the axial direction of the bevel gears 5 and 6. When the rollers 7 and 8 move outward respectively, the output speed will increase continuously and linearly; on the contrary, when the rollers move inward, the output speed will continuously decrease, thereby achieving continuously variable transmission.

III. Slip Rate Calculation

- Nominal Transmission Ratio

The nominal transmission ratio of the new type of bevel gear-roller flat plate CVT is as follows:

Where , , , and are the number of teeth of the bevel gears 1, 3, 2, and 5 respectively; is the speed of the flat plate, and is the speed of the roller; is the radius of the rollers 7 and 8; is the distance from the contact point between the roller and the flat plate to the center of the flat plate, and the size of can be changed through the speed regulation mechanism to achieve continuously variable speed.

- Elastic Slip

Elastic slip is mainly caused by the sliding due to the elastic deformation of the material at the friction contact point. The roller and the flat plate will form an elliptical contact area at the contact point during work and generate sliding, which will affect the transmission accuracy and directly affect the transmission ratio. In the friction wheel drive system, elastic slip is inevitable, so it is necessary to analyze the elastic slip in the calculation of the transmission ratio. The approximate calculation formula of the elastic slip rate [10] is as follows:

Where is the elastic slip rate; is the edge arc radius of the roller; is the elastic modulus; is the Poisson’s ratio; is the tangential resultant force of the contact surface; is the friction coefficient; is the compression force in the contact area; is the short-axis radius of the contact ellipse.

- Geometric Slip

The sliding caused by the change of the geometric relationship between the driving and driven wheels in the friction transmission process is called geometric slip, as shown in Figure 2. When there is no load, the pure rolling point is the midpoint of the contact area. When the load is transmitted, the pure rolling point shifts from to . Assuming that the input angular velocity of the flat plate remains unchanged, due to the sliding effect, the actual output angular velocity of the roller is lower than the theoretical angular velocity . The distance between the two points and is called the node offset amount, and it can be taken as follows for simplified calculation [11]:

Where is the transmission reliability coefficient.

- Corrected Transmission Ratio

Due to the influence of geometric slip and elastic slip, the calculation of the nominal transmission ratio of the CVT is inaccurate, and it needs to be corrected. The corrected transmission ratio is as follows:

It can be seen from Equation (9) that the corrected actual transmission ratio will be slightly larger than the nominal transmission ratio, and the larger the load, the higher the slip rate, and the actual transmission ratio will also increase accordingly.

IV. Power Loss and Contact Friction Efficiency Calculation

Most of the power loss in the CVT is friction power loss, so this paper only analyzes the friction power loss and friction transmission efficiency. Let be any point in the contact area, then the differential expression of the power loss in the friction contact area [13] is:

Where is the sliding speed of any point in the contact area:

Where is the distance from point to the pure rolling point :

By the above equation, the friction power loss of a single contact area can be obtained as:

Where is the maximum contact compressive stress:

Since the designed flat plate and roller in this paper have four symmetrical contact points, the total friction power loss is:

As shown in Figure 2, when the load is borne, both the pure rolling point and the effective circumferential force acting point will shift, and the shift amounts of the two are different. In fact, the effective circumferential force does not act on the pure rolling point , but acts on the point at a distance of from the point . For simplified calculation:

Combining the slip rate and the geometric relationship of each acting point, the efficiency of the friction contact can be obtained:

The friction contact efficiency of the designed new type of bevel gear-roller flat plate CVT can reach more than 90%.

V. Temperature Field Analysis

- Friction Heat Flux

When the roller and the flat plate are in friction transmission, they will generate relative sliding, thereby generating frictional heat, increasing the temperature, and affecting the service life. Therefore, it is necessary to study the friction heat generation and temperature field of the roller and the flat plate. The calculation formula of the friction heat flux [14] is as follows:

Where is the friction heat flux; is the relative sliding speed; is the contact compressive stress:

If the materials of the two contact parts are different, a heat distribution coefficient needs to be introduced. Since the materials of the roller and the flat plate in this paper are the same, the heat is evenly distributed [15], and the heat distribution coefficient is taken as 0.5. If the input heat flux at the contact points of the flat plate and the roller is taken as the average value within one rotation, the average friction heat flux for one rotation can be respectively expressed as:

Where and are the linear velocities of the contact areas of the roller and the flat plate respectively.

The parameters selected for the analysis are shown in Table 1.

| Parameter | Value |

|---|---|

| Distance between the center of the roller and the center of the flat plate (mm) | 25 |

| Friction coefficient | 0.2 |

| Elastic modulus , (GPa) | 200 |

| Poisson’s ratio | 0.3 |

| Radius of the roller (mm) | 50 |

| Transmission reliability coefficient | 1.25 |

| Compression force (N) | 2500 |

| Input speed () | 1500 |

Due to the different relative sliding speeds of each point in the elliptical contact area, the calculated friction heat flux is also different. The maximum sliding speed is about 300 mm/s, the sliding speed at the point is about 135 mm/s, and the average sliding speed is about 200 mm/s. The calculated friction heat flux , .

- Simulation Settings

Simulation analysis is carried out in ANSYS software, where the roller and the flat plate are in friction contact, the roller is the contact geometry, and the flat plate is the target geometry. The calculated friction heat flux is applied to the contact areas divided by the roller and the flat plate as the boundary conditions, and the convective heat transfer coefficient is applied to the whole. As shown in Figure 3.

The mesh element type is selected as solid227, the tetrahedral meshing method is used, with a slow transition and a high smoothing level. In order to further eliminate the influence of the mesh on the calculation results, the number of meshes is gradually increased in this paper, and the mesh size of the contact area is gradually reduced from 1 mm, and solved in turn. When the mesh size of the contact area is less than 0.7 mm, the simulation results obtained by continuing to reduce the mesh size change very little, less than 1%. Finally, the mesh size is determined to be 0.5 mm, and the mesh effect is shown in Figure 4, with the number of nodes being 1,749,730, the number of elements being 1,232,666, the average quality factor being 0.8175, and the average aspect ratio being 1.91.

- Temperature Field Simulation Results

The ambient temperature is 22 °C, and the convective heat transfer coefficient is taken as under the condition of natural convection of air. The initial substep is 250, the minimum substep is 200, the maximum substep is 1000, the time integration is turned on, and the simulation runs for 1800 s, and the temperature result tends to be stable, as shown in Figure 5.

As shown in Figure 5, the highest temperature of the overall structure is 60.881 °C, located in the contact area between the roller and the flat plate, and the temperature gradually decreases from the contact area to the non-contact area, and the overall temperature of the flat plate is higher than that of the roller.

The input speed is one of the important factors affecting the heat flux. The input speed is approximately proportional to the friction heat flux. Doubling the input speed , the sliding speed and the friction heat flux increase proportionally. With other conditions unchanged, the simulation results at a speed of 3000 r/min are shown in Figure 6.

As shown in Figure 6, with the increase of the rotational speed, the temperatures of both the roller and the flat plate rise, the highest temperature reaches 99.75 °C, and the temperature field distribution gradient under different rotational speed conditions is approximately the same. The larger the friction heat flux, the greater the temperature rise, but the two are not directly proportional.

Under the working condition of a rotational speed of 3000 r/min, in order to simulate the temperature field under air-cooling conditions, the convective heat transfer coefficient is increased to gas forced convection (take the convective heat transfer coefficient as ), and the simulation results are shown in Figure 7.

As shown in Figure 7, under the air-cooling conditions, the roller and the flat plate can be cooled more fully, the temperature drops by more than 50%, and the highest temperature is less than 44 °C. The frictional temperature rise of the new type of bevel gear-roller flat plate CVT is within the design allowable range, and the design scheme is feasible.

VI. Conclusions

- The rotational speed is one of the important factors affecting the frictional temperature rise of the roller and the flat plate. The temperature of the roller and the flat plate will rise with the increase of the rotational speed, and the main reason is that the increase of the rotational speed makes the sliding speed increase, resulting in more frictional heat.

- With the increase of the compression force, both the offset amount of the pure rolling point and the offset amount of the effective circumferential force will increase, the friction power loss will increase, and the friction efficiency will decrease. At the same time, the compression force has a great influence on the friction heat flux. With the increase of the compression force, not only the sliding speed will increase, resulting in more frictional heat, but also the contact area will increase, making the area of frictional heat larger, thus having a more obvious impact on the temperature rise.

- The new type of bevel gear-roller flat plate CVT has a high friction efficiency, which can reach more than 90%, the frictional heat generation is relatively small, the temperature rise is low, and there is a great improvement compared with the existing friction-type CVTs, which meets the design requirements.