Gear hobbing serves as a crucial semi-finishing process in cylindrical gear manufacturing, offering high efficiency and cost-effectiveness. This study establishes kinematic models for gear hobbing and honing processes, derives mathematical representations of tooth surfaces, and proposes a multi-axis linkage-based pre-modification method for gear hobbing. By integrating sensitivity analysis with dynamic programming optimization, we achieve uniform honing allowances and enhanced machining accuracy.

Mathematical Modeling of Gear Hobbing and Honing Processes

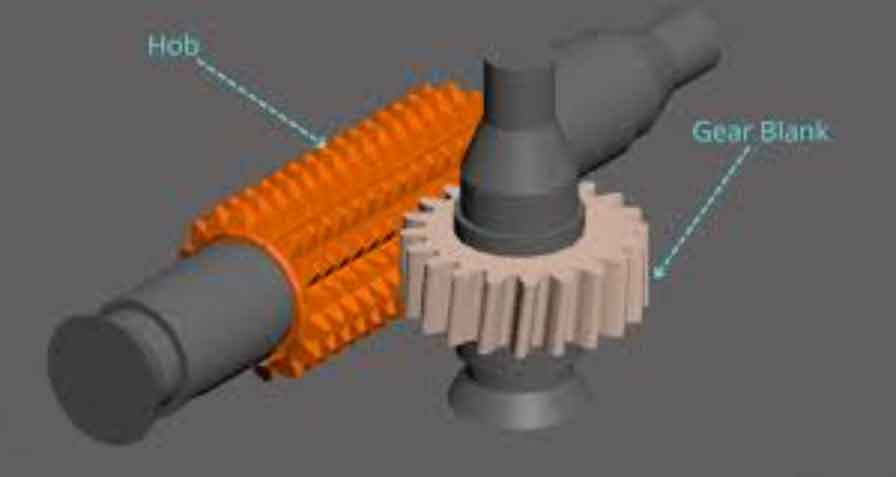

The kinematic relationship in gear hobbing involves synchronized rotation between the hob and workpiece alongside axial feed motion. The coordinate systems are defined as follows:

| Coordinate System | Description |

|---|---|

| S1(O1x1y1z1) | Workpiece-fixed system |

| S2(O2x2y2z2) | Hob-fixed system |

| Sg(Ogxgygzg) | Workpiece-motion system |

| Sh(Ohxhyhzh) | Hob-motion system |

The hob-workpiece center distance \(a\) and shaft angle \(\Sigma\) are calculated as:

$$ a = r_g \pm r_h $$

$$ \Sigma = \beta_g – \beta_h $$

where \(r_g\) and \(r_h\) denote pitch radii, \(\beta_g\) and \(\beta_h\) represent helix angles. The transmission ratio is:

$$ i_{gh} = \frac{Z_h}{Z_g} $$

The axial feed distance \(\zeta\) relates to hob rotation angle \(\phi_h\):

$$ \phi_g = \frac{Z_h}{Z_g} \phi_h + \frac{\zeta}{r_g \tan \beta_g} $$

Tooth Surface Formulation

The basic rack profile is defined parametrically:

$$ \mathbf{r}_n(u) = [x_n(u), 0, z_n(u), 1]^T $$

The hob thread surface is generated via coordinate transformation:

$$ \mathbf{r}_w(u,v,\phi_w) = \mathbf{M}_{wf} \cdot \mathbf{M}_{fr} \cdot \mathbf{r}_n(u) $$

The meshing equation satisfies:

$$ f(u,v,\phi_w) = \frac{\partial \mathbf{r}_w}{\partial u} \times \frac{\partial \mathbf{r}_w}{\partial v} \cdot \frac{\partial \mathbf{r}_w}{\partial \phi_w} = 0 $$

The generated gear tooth surface becomes:

$$ \mathbf{r}_g(u,v,\phi_h,\zeta) = \mathbf{M}_{g1} \cdot \mathbf{M}_{12} \cdot \mathbf{M}_{23} \cdot \mathbf{M}_{3h} \cdot \mathbf{r}_w $$

Multi-Axis Hobbing Pre-Modification

For topological modification, radial (Y-axis) and swivel (B-axis) motions are coordinated through second-order polynomials:

$$ a_i = a + b_0 + b_1\zeta + b_2\phi_h + b_3\zeta^2 + b_4\phi_h^2 + b_5\zeta\phi_h $$

$$ \Sigma_i = \Sigma + b_6 + b_7\zeta + b_8\phi_h + b_9\zeta^2 + b_{10}\phi_h^2 + b_{11}\zeta\phi_h $$

The normal machining allowance \(h_i\) at grid points is:

$$ h_i = (\mathbf{r}_{gi}^m – \mathbf{r}_{gi}) \cdot \mathbf{n}_{gi} $$

Sensitivity coefficients \(\partial h_i / \partial b_j\) form the matrix \(\mathbf{H}\) relating allowance variations to parameter adjustments:

$$ \{\Delta h_i\} = \mathbf{H} \{\Delta b_j\} $$

| Coefficient | Mean \(\Delta h\) (mm) | Effect Direction |

|---|---|---|

| \(b_0\) | 0.0177 | Radial offset |

| \(b_3\) | 0.8390 | Strong profile influence |

| \(b_{10}\) | 1.6800 | Dominant swivel effect |

Honing Allowance Control via Dynamic Programming

The target honing allowance \(h_{1i}\) is defined as:

$$ h_{1i} = (\mathbf{r}_{g1i}^m – \mathbf{r}_{gi}) \cdot \mathbf{n}_{gi} $$

Initial modification parameters are solved via singular value decomposition (SVD):

$$ \mathbf{H} = \mathbf{U\Sigma V}^T $$

$$ \{\Delta b_j\} = \mathbf{V}\Sigma^{+}\mathbf{U}^T \{\Delta h_i\} $$

Dynamic programming optimizes parameters through multi-stage decision-making:

$$ r_{n+1} = M(r_n, l_n) $$

$$ \min \sum_{1 \leq i \leq n} c_i(r_i, l_i) = \min \sum_{j=1}^{35} \left| (\mathbf{r}_{gij}^m – \mathbf{r}_{gij}) \cdot \mathbf{n}_{gij} \right| $$

Optimization results demonstrate significant error reduction:

| Method | Max Error (mm) | Mean Error (mm) | Variance |

|---|---|---|---|

| Sensitivity matrix | 0.4023 | 0.0291 | 9.9e-4 |

| Dynamic programming | 0.0092 | 0.0023 | 1.1e-5 |

Virtual Verification

A 5-axis gear hobbing machine was modeled in VERICUT with NC code implementing the optimized modification functions. Post-simulation comparison showed uniform allowances:

| Node | Deviation (mm) | Coordinate (mm) |

|---|---|---|

| 1 | 0.0019 | (-33.45, -1.41, 0.00) |

| 17 | 0.0317 | (-35.81, -1.56, 1.60) |

| 35 | -0.0041 | (-38.98, -1.87, 4.80) |

Results confirm that gear hobbing pre-modification effectively controls honing allowances, enabling high-precision hobbing-honing synergy.