1. Introduction

1.1 Research Background

Aviation high-speed gear pumps play a crucial role as power output devices in aircraft hydraulic systems. To meet the demands of high thrust-to-weight ratio and low fuel consumption in aircraft development, gear pumps need to increase flow without enlarging their size and mass, which requires higher rotational speeds. However, high speeds exacerbate the wear of gear end face friction pairs in gear pumps, reducing service life and volumetric efficiency, and even affecting the stable and reliable operation of the aircraft hydraulic control system in severe cases.

1.2 Research Status of Gear Pump Friction Pairs

Scholars at home and abroad have conducted extensive research on the tribological characteristics of gear pump friction pairs to understand wear mechanisms and control methods. Szwemin et al. established a three-dimensional gear pump model to obtain the variation law of gear end face liquid film pressure over time. Guo et al. combined theory and experiments to study gear pumps and found that an increase in outlet pressure causes flow field fluctuations in the gear pump, intensifying gear end face wear. Feng Yongbao established a coupled model of the gear end face friction pair in a gear pump using the thermal-fluid-solid coupling method and found that the end face oil film pressure decreases circumferentially and that uneven wear mainly occurs in the low-pressure region of the oil film. Liu Wei et al. studied high-pressure gear pumps and found that the overturning moment caused by the asymmetric distribution of pressure in the gear working chamber, leading to the inclination of the floating side plate, is one of the important reasons for end face wear. To improve the lubrication conditions of the gear end face, Thiagarajan et al. established a new fluid-structure interaction model for the end face lubrication of an asymmetric balanced gear pump and achieved better axial balance by determining the balance area on the floating side plate. Dhar et al. proposed an axial motion coupling model for gear friction pairs and reduced the end face wear and friction power consumption of the friction pair by optimizing the floating side plate structure. It can be seen that insufficient lubrication of the gear end face friction pair is the main cause of end face wear during high-speed operation of the gear pump, and improving lubrication through reasonable design of the friction pair structure is one of the important ways to increase service life.

1.3 Research Status of Surface Textures

Surface textures have been shown to effectively improve the lubrication performance between friction pairs. Hamilton et al. used laser processing technology to create micro-nano textures on the surface of seals in the 1960s and found that the textures could form a certain hydrodynamic pressure effect and reduce wear. Li Yang et al. experimentally studied the tribological properties of the valve plate pair of a piston pump with and without textures and found that the textured valve plate pair could effectively reduce the friction coefficient. Gropper et al. studied the effect of surface textures on the performance of thrust bearings and found that reasonable texture design could effectively improve the bearing friction torque and reduce the friction temperature rise. Currently, lubrication textures on the friction pair interface mainly include grooves and holes. In groove design, John Crane Company designed a spiral groove dry gas seal, which is widely used due to its excellent hydrodynamic lubrication performance. In recent years, scholars at home and abroad have carried out a large number of studies on groove optimization design. The Tesla valve has received attention and application due to its ingenious structure. Studies have shown that when the fluid flows in the reverse direction, the fluid will experience a fluid blocking effect and an increase in pressure head every time it passes through a wing-shaped obstacle. When multiple Tesla valves are connected, the reverse flow causes the pressure in the wing-shaped region to increase and gradually establishes multiple reverse flow pressure regions, forming a hydrodynamic effect. Wang Yan et al. proposed a new non-contact sealing groove structure based on the reverse flow blocking effect of the Tesla valve and found that the Tesla valve-like groove has excellent comprehensive sealing performance. In hole design, Qiu et al. theoretically studied the effects of circular, triangular, and elliptical hole textures on the opening force and friction coefficient of gas-lubricated bearings and pointed out that the elliptical hole textured bearing has a higher opening force and a lower friction coefficient. Hu et al. further experimentally proved that the elliptical hole texture on the friction pair end face can play a good role in reducing friction. Bai Shaoqian et al. experimentally studied the opening characteristics of the directional elliptical hole end face dry gas seal and found that the arrangement of elliptical holes has a great influence on the gas hydrodynamic performance of the end face. Scholars have also studied the lubrication performance of composite textures on friction pairs. Ruan Hongyan et al. studied the effect of composite textures on the lubrication performance of friction pairs and found that the bearing capacity generated by the composite texture is significantly greater than that generated by a single texture. Jia et al. studied and pointed out that the composite texture composed of grooves and holes can form a moderate liquid film thickness, solving the problem of insufficient groove lubrication performance.

1.4 Research Significance and Objectives

In summary, surface textures can effectively improve friction and wear problems, but their application in gear pump gear end face friction pairs has been rarely reported. Based on the excellent comprehensive performance of the Tesla valve-like groove and the elliptical groove, and considering the special shape and structure characteristics of the gear pump gear end face (the inner end face is a continuous annular end face and the outer end face is a non-continuous end face with protruding teeth), this paper designs a Tesla valve-like groove on the continuous annular end face of the gear and elliptical holes on the non-continuous end face with protruding teeth to form a Tesla valve-like groove-elliptical hole composite texture. The lubrication characteristics of the gear end face composite texture friction pair are systematically studied under different working conditions, and the opening force and leakage rate of the end face with and without textures under different working conditions and structural parameters are compared and analyzed, providing a certain theoretical reference for the design and application of the lubrication texture on the gear end face of high-speed external gear pumps.

2. Calculation Model

2.1 Gear Pump End Face Friction Pair Structure

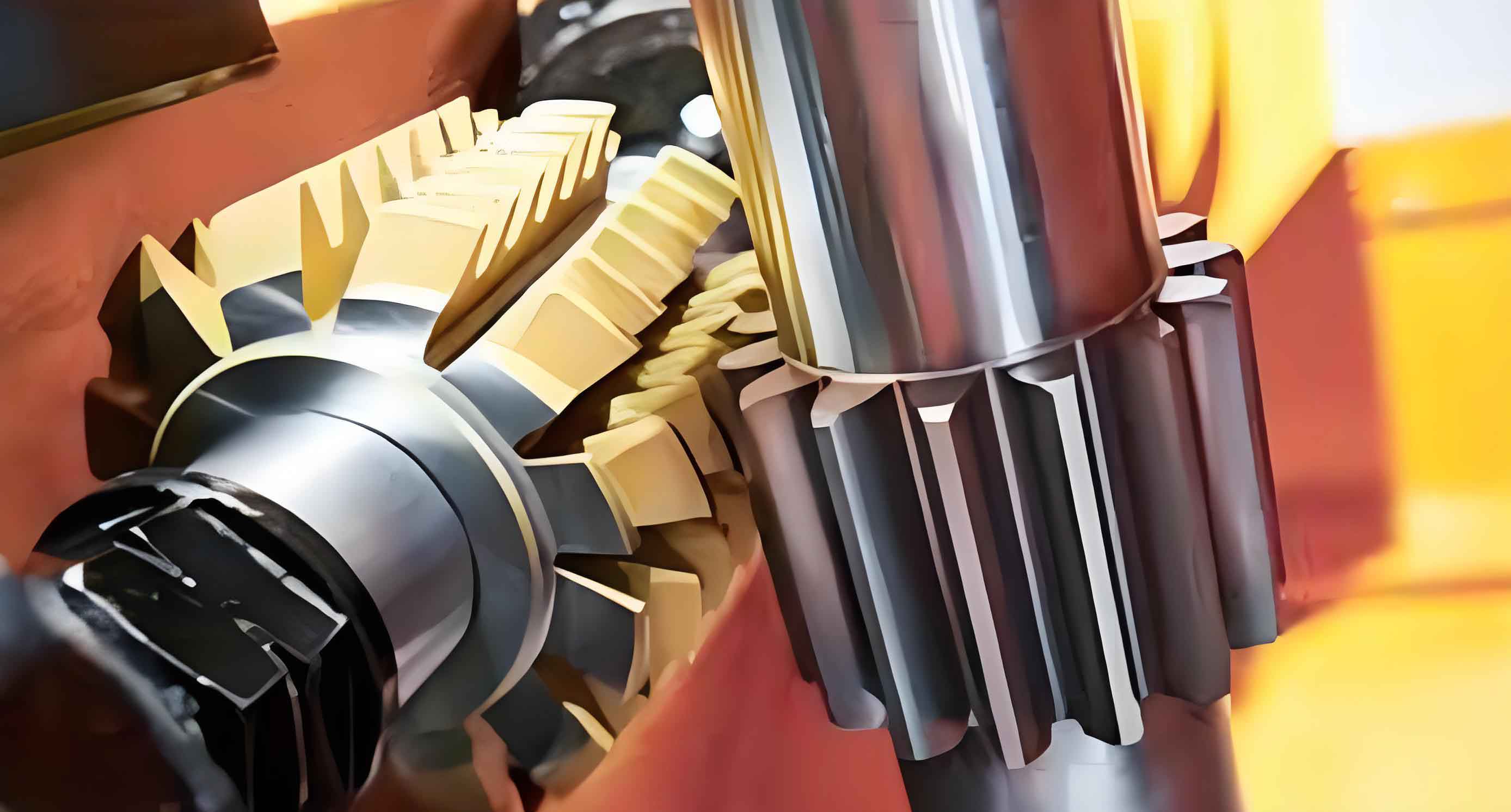

The three-dimensional sectional view of a high-speed external gear pump with a Tesla valve-like groove-elliptical hole composite texture on the gear end face is shown in Figure 1(a). Figure 1(b) is a schematic cross-sectional view of the gear end face friction pair. It can be seen that the gear and the floating side plate form a relative motion friction pair. When the gear rotates at high speed, a micron-thick lubricating liquid film will be formed between the gear end face friction pairs under the action of the hydrodynamic pressure effect of the lubricating texture. To ensure good sealing and non-contact operation of the gear end face friction pair, the design film thickness needs to be controlled within an appropriate range. To achieve this, on the one hand, advanced laser etching technology is required to ensure the machining accuracy of the groove depth as much as possible. On the other hand, the actual machining situation also needs to be considered, and the theoretical balance film thickness is designed reversely based on the measured groove depth and mechanical balance.

2.2 Geometric Model

The geometric model of the Tesla valve-like groove-elliptical hole composite texture end face is shown in Figure 2, which includes two parts. The first part is the Tesla valve-like groove composed of a spiral groove and a return groove. The spiral groove profile is a classical logarithmic spiral, and the radius R of any point on it is given by equation (1). The return groove profile is composed of multiple tangent circular arcs, and the Tesla valve-like groove is opened on the inner annular surface of the gear end face. The second part is the elliptical hole texture, which is opened on the gear tooth end face. To study the influence of the groove depth of each groove unit in the Tesla valve-like groove, the height difference at the junction of the spiral groove and the return groove is defined as Δh (spiral groove depth h1, return groove depth h2, Δh = h1 – h2), and the shape factor of the elliptical hole is defined as γ = b/a and the inclination angle φ. The shape factor γ and the inclination angle φ jointly characterize the directivity of the elliptical hole. The specific parameters used in this calculation are shown in Table 1, and during the calculation process, unless otherwise specified, the other parameters remain unchanged except for the studied parameters.

2.3 End Face Liquid Film Flow Field Basic Assumptions

Based on the basic theory of fluid mechanics and the characteristics of the fluid medium in the textured end face, the following assumptions are made:

- The fluid in the end face is regarded as a continuous medium flow, the fluid temperature and viscosity remain unchanged, and the end face liquid film is regarded as a complete fluid film.

- The influence of body forces on the flow field is not considered.

- There is no relative slip in the fluid film on the end face, and the influence of the roughness between the two end faces is ignored.

- The influence of friction heat on the medium is not considered.

- The influence of end face deformation and system vibration during the working process on the flow field is not considered.

3. Analysis Model

3.1 Flow State Judgment Equation

To further determine the fluid flow state of the gear friction pair end face, the method in reference [25] is used to judge the flow state of the end face liquid film by the flow factor, and its calculation method is as follows. The fluid flow state is defined as laminar flow when ζ < 9/16, turbulent flow when ζ > 1, and transition zone when 9/16 < ζ < 1. The circumferential average velocity is shown in equation (3), and the radial average velocity is shown in equation (4). According to the numerical simulation working conditions and structural parameters, the Reynolds numbers and the flow factor are calculated, and it is determined that the laminar flow model is adopted.

3.2 Control Equations

Since the end face liquid film cavitates due to negative pressure, the Mixture multiphase flow model is selected for the simulation model, and its multiphase flow continuity and momentum control equations are shown in equations (5) and (6). The cavitation model selects the Schnerr-Sauer model, and its basic control equations are shown in equations (9)-(11). The mixture density and dynamic viscosity are calculated by equations (7) and (8). By solving the above nonlinear partial differential equations using fluid dynamics software, the end face liquid film pressure field, velocity field, cavitation distribution area can be obtained, and the lubrication characteristic parameters such as the opening force and leakage rate can be calculated. The calculation expressions of the opening force and leakage rate are shown in equations (12) and (13).

3.3 Inlet Pressure Boundary Conditions

The inlet pressure boundary condition of the liquid film between the gear end face frictions is determined by simulation. The gear pump pressure cloud diagram is shown in Figure 3, and the left gear boundary pressure is extracted (considering the symmetry of the gear pump structure, the left gear is taken as the research object), and the gear boundary pressure is converted into the inlet pressure boundary of the liquid film.

3.4 Modeling and Mesh Generation

The left gear end face liquid film is taken for simulation analysis, and it is assumed that there is a complete parallel liquid film between the floating side plate and the gear. The calculation region is shown in Figure 4. The inner diameter side of the liquid film is the pressure outlet, and the outer diameter side is the pressure inlet. The texture is opened on the gear end face, the upper surface of the liquid film is in contact with the gear end face and is set as a rotational wall, and the lower surface is in contact with the floating side plate and is set as a stationary wall. The simulation calculation is carried out using Fluent. The Mixture multiphase flow model is used in the calculation, the SIMPLEC algorithm is adopted, and the PRESTO format is used for the pressure term.

3.5 Mesh Independence Verification

To reduce the influence of the number of grids on the simulation results, a mesh independence analysis is required. Figure 5(a) shows the variation curve of the opening force with the number of grid layers in the film thickness direction. It can be seen that when the liquid film non-groove region film thickness adopts 5 layers of grids and the groove region adopts 9 layers of grids, good calculation accuracy and speed can be ensured. Under the above grid layer conditions, the influence of the grid size on the opening force is further studied by changing the grid size. As shown in Figure 5(b), the opening force gradually increases with the increase of the grid number and tends to be stable when the grid number reaches 1.2 million. To ensure the calculation accuracy and speed, the grid number in this paper is about 1.3 million.

4. Results and Analysis

4.1 Simulation Method Correctness Verification

The simulation methods of the gear end face liquid film and the dry gas seal spiral groove liquid film are similar, both are micro-scale liquid films, and the fluid flow states are similar. Therefore, the same grid division and simulation calculation methods are used. To verify the correctness of the method in this paper, the simulation results are compared and verified with the calculation results in reference [30]. As shown in Figure 6, the maximum error between the calculation result and the literature result is less than 5%, indicating that the calculation method in this paper can accurately simulate the flow field results.

4.2 Pressure and Velocity Field Distribution

Figures 7(a) and (b) show the pressure distribution cloud diagrams of the liquid film on the gear end face with and without textures, respectively. It can be seen that the maximum value of the end face film pressure after opening the texture is significantly increased. This is because the texture makes the end face have a film thickness convergence region, and when the fluid flows at high speed to the convergence region, the pressure will increase due to the fluid squeezing effect. At the same time, it can be found that when there is no texture, the end face film pressure shows a non-periodic distribution along the circumferential direction due to the non-uniform inlet pressure boundary, which will cause an obvious overturning moment on the gear end face and aggravate the uneven wear. After opening the texture, the high-pressure region generated near the groove root increases the overall film pressure of the liquid film, and the degree of non-periodic distribution of the film pressure is significantly reduced, and the force balance will be improved. Therefore, from the perspective of film pressure distribution, opening the texture can not only increase the opening ability of the end face liquid film but also improve the stability of the liquid film support.

Figures 8(a) and (b) show the velocity distribution cloud diagrams and streamline diagrams of the liquid film on the gear end face with and without textures, respectively. It can be seen that the flow field streamline of the liquid film on the gear end face without texture is spiral and leaks to the outlet. For the gear end face with texture, the fluid flow is guided by the pumping direction of the texture, and due to the existence of the return groove, part of the fluid will be pumped upstream, reducing the end face leakage to a certain extent.

To further quantitatively compare the pressure change laws of the gear end face with and without textures, the pressure data are extracted along the circumferential and radial directions, respectively. Figures 9 and 10 show the circumferential and radial variation curves of the liquid film pressure at different positions on the end face with and without textures, respectively. It can be seen that the pressure change of the liquid film on the end face without texture is relatively gentle, and the pressure value is relatively small. The maximum pressure position is in the pump outlet region, which is mainly because the boundary pressure in the pump outlet region is the largest. The liquid film pressure on the end face with texture is much larger than that on the end face without texture. Although the liquid film pressure fluctuates significantly along the circumferential direction, the peak and trough values only change slightly. The comprehensive liquid film pressure laws in Figures 9 and 10 can further quantitatively illustrate that opening the texture on the end face can not only significantly improve the hydrodynamic lubrication ability of the friction pair but also reduce the adverse effects caused by the non-uniform pressure boundary, which has a positive effect on homogenizing the end face pressure distribution and reducing the end face uneven wear.

4.3 Influence of Working Condition Parameters on Lubrication Characteristics

4.3.1 Influence of Film Thickness h

Figure 11 shows the influence curves of the film thickness h on the opening force and leakage rate of the liquid film on the end face with and without textures. It can be seen that with the increase of h, the opening force of the textured end face liquid film first decreases rapidly and then tends to be flat, and the leakage rate first increases slowly and then shows a linear increasing trend. The opening force of the liquid film on the end face without texture hardly changes with h, and the leakage rate increases with the increase of h, first slowly and then quickly. From the perspective of numerical values, the opening force and leakage rate of the textured end face liquid film are larger than those of the end face without texture. Under the premise of ensuring a small leakage, the textured end face liquid film can effectively improve the lubrication performance and ensure long-term non-contact operation.

4.3.2 Influence of Outlet Pressure P

Figure 12 shows the influence curves of the gear pump outlet pressure P on the opening force and leakage rate of the liquid film on the end face with and without textures. It can be seen that with the increase of P, the opening force and leakage rate of the liquid film on the end face with and without textures increase slowly. Since the influence area of the outlet pressure is mainly the oil discharge area, and the influence on the liquid film pressure boundary is not large, the influence on the performance parameters such as the opening force and leakage rate is small. Therefore, in the design process of the gear end face lubrication performance, the influence of the outlet pressure can be appropriately ignored to simplify the calculation and analysis workload.

4.3.3 Influence of Rotational Speed n

Figure 13 shows the influence curves of the gear pump rotational speed n on the opening force and leakage rate of the liquid film on the end face with and without textures. It can be seen that with the increase of n, the opening force and leakage rate of the textured end face liquid film increase significantly, while the opening force and leakage rate of the liquid film on the end face without texture change little. This is because there is no hydrodynamic pressure effect on the end face without texture, and the rotational speed has little influence on the film pressure of the end face without texture, and the circumferential shear flow brought by the rotational speed will not affect the leakage rate of the end face. However, after opening the texture, the higher the rotational speed, the stronger the hydrodynamic pressure effect and the pumping effect of the texture, so the opening force and leakage rate will be affected by the rotational speed. When the rotational speed is large, it is necessary to focus on optimizing the gear end face structural parameters with the goal of leakage control.

4.4 Influence of Structural Parameters on Lubrication Characteristics

4.4.1 Influence of Spiral Groove Depth

When the height difference in the Tesla valve-like groove is 0, the influence of the spiral groove depth on the opening force and leakage rate of the textured end face liquid film is shown in Figure 14. With the increase of , the opening force and leakage rate of the textured end face liquid film first increase rapidly and then tend to be flat. When is 12, the liquid film has better opening performance, but at this time, the leakage rate is also relatively large. Considering the opening and leakage control of the end face liquid film comprehensively, it is advisable to take the value of in the range of 7 – 9.

4.4.2 Influence of Height Difference between Spiral Groove and Return Groove

The designed height difference between the spiral groove and the return groove is helpful to improve the hydrodynamic pressure effect. Figure 15 shows the opening force and leakage rate under different height differences . It can be seen that with the increase of , the opening force of the textured end face liquid film fluctuates. This is because the change of will lead to the change of the hydrodynamic pressure intensity generated near the groove roots of the spiral groove and the return groove. When is in the range of 5 – 6, the hydrodynamic pressure intensity generated by the Tesla valve-like groove is stronger, so the opening force is larger. The leakage rate decreases with the increase of . Considering the opening and leakage control comprehensively, it is advisable to take the value of in the range of 5 – 6.

4.4.3 Influence of Inclination Angle of Elliptical Hole

Figure 16 shows the influence curve of the inclination angle of the elliptical hole on the gear end face on the opening force and leakage rate of the textured end face liquid film. It can be seen that when increases from -50° to 0°, the opening force first decreases and then increases. With the further increase of , the opening force begins to decrease. This is because when = -50°, the hydrodynamic pressure effect of the elliptical hole is the weakest, but the superposition effect between the end of the elliptical hole and the Tesla valve-like groove is the strongest. With the increase of , the hydrodynamic pressure effect of the elliptical hole increases, but the superposition effect between the grooves weakens, resulting in the fluctuation of the opening force. During the whole process of increasing , the leakage rate continues to decrease because the increase of improves the upstream pumping capacity of the elliptical hole. Considering the opening and leakage control comprehensively, it is advisable to take the value of in the range of 0 – 10°.

4.4.4 Influence of Shape Factor of Elliptical Hole

Figure 17 shows the influence curve of the shape factor of the elliptical hole on the gear end face on the opening force and leakage rate of the textured end face liquid film. It can be seen that the opening force and leakage rate of the end face liquid film decrease with the increase of . This is because as gradually increases to 1, the elliptical hole gradually becomes a circular hole, and its hydrodynamic pressure effect and directional guiding effect gradually weaken, so the opening force and leakage rate continue to decrease. Considering the opening and leakage control comprehensively, within the range of research parameters in this paper, it is advisable to take the value of in the range of 0.4 – 0.5.

5. Conclusions

5.1 The Effect of Textured End Face on Lubrication

Opening a hydrodynamic lubrication texture on the end face can not only effectively open the end face by increasing the fluid film pressure but also make the pressure distribution more uniform along the circumferential direction, which has a positive effect on improving the stability of the liquid film support and reducing the end face uneven wear.

5.2 The Influence of Working Condition Parameters

Compared with the liquid film on the gear end face without texture, the working condition parameters such as film thickness, outlet pressure, and rotational speed have a greater influence on the opening force and leakage rate of the textured end face liquid film. Under the working conditions of high speed and high outlet pressure, the textured end face can ensure that the gear end face friction pair has better leakage control and lubrication performance.

5.3 The Optimization of Structural Parameters

Within the range of calculation working conditions and structural parameters in this paper, to ensure that the gear end face friction pair of the high-speed gear pump has excellent opening and leakage control properties, it is advisable to take in the range of 7 – 9, in the range of 5 – 6, in the range of 0 – 10°, and in the range of 0.4 – 0.5.

In summary, this research provides a theoretical basis and reference for the design and optimization of the lubrication texture on the gear end face of aviation high-speed gear pumps, which is of great significance for improving the performance and service life of gear pumps. Future research can further explore the influence of different texture combinations and working conditions on the lubrication characteristics of gear pumps, and conduct more in-depth experimental research to verify and improve the theoretical model.