1. Introduction

In the landscape of modern manufacturing, the demand for high – precision components is on the rise, especially in industries such as robotics, aerospace, and defense. Cycloid gear forming grinding machines play a crucial role in the production of precision gears. The 立柱 (column) of these machines is a key structural element that significantly influences the machining accuracy. However, optimizing the column’s structure is a complex task. This paper presents a multi – stage optimization method for the cycloid gear forming grinding machine column, integrating topological optimization, structural bionics, and size optimization.

1.1 Background and Motivation

With the rapid development of various high – tech industries, the requirements for the performance of precision machine tools are becoming more stringent. Precision machine tools need to be faster, more efficient, and highly accurate. The cycloid gear forming grinding machine is a vital piece of equipment for manufacturing high – precision cycloid gears. The column of this machine, as a key foundation part and guiding element, directly affects the grinding accuracy. If the column has poor static and dynamic performance, it will lead to inaccurate machining of gears, affecting the quality of the final products.

Previous research on optimizing machine tool structures mainly focused on single – method optimizations. For example, some studies used finite – element analysis to analyze the static and dynamic characteristics of machine tool components, while others applied topological optimization for lightweight design. However, these single – method optimizations often cannot fully meet the complex requirements of modern machine tool design. A comprehensive optimization approach is needed to simultaneously improve multiple performance indicators such as reducing the mass of the column, increasing its stiffness, and enhancing its vibration – resistance.

1.2 Objectives of the Research

The main objective of this research is to develop a multi – stage multi – objective optimization design method for the cycloid gear forming grinding machine column. This method aims to achieve comprehensive optimization of the column’s mass, first – order natural frequency, maximum stress, and deformation displacement. By doing so, the overall performance of the grinding machine can be enhanced, and the machining accuracy of cycloid gears can be improved.

2. Prototype Cycloid Gear Forming Grinding Machine 3D Modeling

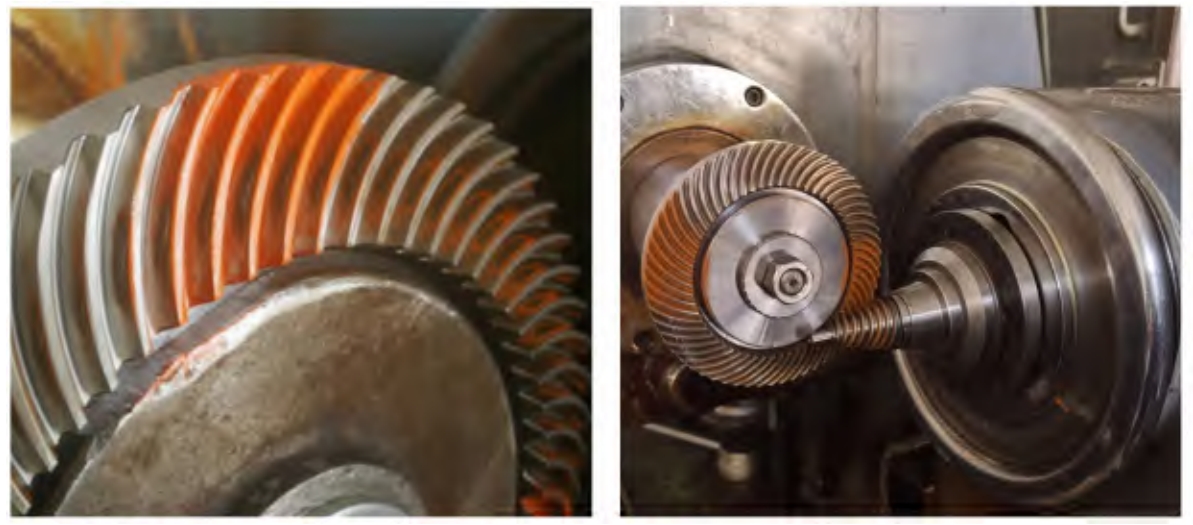

2.1 Selection of Prototype Machine

The Y7654A type cycloid gear grinding machine, developed by Qinchuan Machine Tool Factory, is a representative cycloid gear grinding machine in China. However, compared with its foreign counterparts of the same period, it has lower machining accuracy. The root cause lies in the insufficient static and dynamic performance of its machine structure. Therefore, this machine is selected as the prototype for the development of a new cycloid gear forming grinding machine.

2.2 Development of 3D Model

Based on the Y7654A type cycloid gear grinding machine, a three – dimensional model of the prototype cycloid gear forming grinding machine is designed. The model includes key components such as the grinding system, column, turntable, and bed. The column is of particular importance as it is the focus of this research. The overall structure of the machine is shown in Figure 1.

| Component | Function |

|---|---|

| Grinding system | Responsible for grinding the cycloid gear |

| Column | Supports the grinding system and provides guidance, affecting machining accuracy |

| Turntable | Holds and rotates the workpiece during machining |

| Bed | Serves as the base for the entire machine, providing stability |

2.3 Importance of the Column in the Machine

The column is a critical part of the cycloid gear forming grinding machine. It is like the “backbone” of the machine. As a guiding element, it ensures the accurate movement of the grinding system. If the column has large deformation or low stiffness, the grinding process will deviate from the ideal path, resulting in inaccurate gear profiles. Moreover, the column also bears various loads during the machining process, including the weight of the grinding system, the cutting force generated during grinding, and its own weight. Therefore, improving the performance of the column is essential for enhancing the overall performance of the machine.

3. Static and Dynamic Analysis of the Prototype Column

3.1 Finite Element Model of the Prototype Column

The first step in analyzing the prototype column is to create its finite – element model. Using 3D modeling software, the column is modeled as a cantilever beam structure, which is consistent with its actual working conditions. The material of the column is set as gray cast iron, with a density of \(7200kg/m³\), a Poisson’s ratio of 0.28, and an elastic modulus of 110GPa. After mesh division, the finite – element model has 87979 nodes and 51074 elements, as shown in Figure 2.

| Parameter | Value |

|---|---|

| Material | Gray cast iron |

| Density | \(7200kg/m³\) |

| Poisson’s ratio | 0.28 |

| Elastic modulus | 110GPa |

| Number of nodes | 87979 |

| Number of elements | 51074 |

Boundary conditions are crucial for accurate analysis. A uniformly distributed load with a certain magnitude in the negative x – axis direction is applied to the column’s guide surface, and a uniformly distributed load of 0.05MPa in the negative Z – axis direction is applied to the top of the column. The self – weight of the column is also considered, and the bottom of the column is fixed – constrained. The boundary conditions are shown in Figure 3.

| Load Location | Load Type | Magnitude | Direction |

|---|---|---|---|

| Column guide surface | Uniformly distributed load | [Value] | Negative x – axis |

| Column top | Uniformly distributed load | 0.05MPa | Negative Z – axis |

| Column | Self – weight | – | – |

| Column bottom | Fixed constraint | – | – |

3.2 Static Analysis of the Prototype Column

After setting up the model and boundary conditions, a static analysis is carried out. The results of the static analysis show that the maximum stress of the prototype column is 0.56073MPa, and the deformation displacement is 0.0057636mm. The stress distribution and displacement distribution are shown in Figure 4 and Figure 5 respectively. These results provide a baseline for evaluating the performance of the optimized column.

| Performance Indicator | Value |

|---|---|

| Maximum stress | 0.56073MPa |

| Deformation displacement | 0.0057636mm |

3.3 Modal Analysis of the Prototype Column

Modal analysis is an important part of understanding the dynamic characteristics of the column. With the same material properties and constraint conditions as in the static analysis, the first six – order vibration mode diagrams of the column are obtained, as shown in Figure 6. The natural frequencies of the first six orders are also calculated, as shown in Table 1.

| Order | Natural Frequency (Hz) |

|---|---|

| 1 | 183.25 |

| 2 | 189.39 |

| 3 | 471.44 |

| 4 | 805.78 |

| 5 | 812.46 |

| 6 | 887.89 |

4. Three – Stage Comprehensive Optimization Design Process

4.1 Topological Optimization of the Column Body

Topological optimization is a powerful tool for finding the optimal material distribution within a given design space. In this research, the objective function is set as the structural compliance, and the constraint condition is the material volume fraction. By using the continuous – body structure topological – optimization method, the layout of the column body structure is improved.

The results of topological optimization are shown in Figure 7. This optimization has several advantages. First, the overall iteration speed is fast. Taking the compliance under static analysis as the objective function, it converges rapidly after 28 iterations. Second, the lightweight effect is obvious, as the mass of the column is significantly reduced. Third, the optimized structure is practical. The retained design area with a cell density of 0.4 or more can greatly improve the stiffness, and it is easy to manufacture in actual production.

| Advantage of Topological Optimization | Description |

|---|---|

| Fast iteration speed | Converges after 28 iterations with static – analysis compliance as the objective function |

| Obvious lightweight effect | Significantly reduces the mass of the column |

| Practical structure | Retained high – density areas improve stiffness and are easy to manufacture |

4.2 Bionic Structure Optimization of the Column

4.2.1 Principles of Structural Bionics

Structural bionics combines engineering mechanics and similarity theory. It studies the stress – bearing laws of different organisms at various structural levels. By analyzing the similarities in structure, force, and function between the bionic object and the research object, a bionic structure similar to the bionic object can be designed to improve performance.

4.2.2 Selection of Bionic Objects

Two natural structures, the veins of the Victoria amazonica leaf and the petiole of the banana plant, are selected as bionic objects.

- Victoria amazonica leaf veins: In terms of structure, the cross – and – longitudinal layout of its primary, secondary, and tertiary veins is similar to the rib – plate layout in the machine tool column. Functionally, the leaf veins support the large leaves of the Victoria amazonica, just as the column supports the grinding system of the machine tool. In terms of load, the column bears external loads such as grinding force, motor weight, and self – weight, while the Victoria amazonica leaf bears wind load, its own weight, and water – surface fluctuation forces. The load – bearing forms are highly similar.

- Banana petiole: Structurally, both the banana petiole and the column contain continuous and discrete structures. Functionally, the banana petiole connects and supports the banana leaf, similar to the column’s function of bearing the load of the grinding components and connecting the bed. In terms of load, the column bears multiple loads during machining, and the banana petiole bears the wind load and the weight of the leaf.

4.2.3 Design of Bionic Structure

Based on the topological – optimization results and the bionic design space, the rib – plate structure inside the column body is optimized. The bionic column structure and the bionic logic evolution process are shown in Figure 8 and Figure 9 respectively. This bionic design can effectively improve the overall performance of the column.

| Bionic Object | Structural Similarity | Functional Similarity | Load Similarity |

|---|---|---|---|

| Victoria amazonica leaf veins | Similar rib – plate layout | Support function | Similar load – bearing forms |

| Banana petiole | Continuous and discrete structures | Connecting and supporting function |

4.3 Size Optimization Based on the Response – Surface Method

4.3.1 Establishment of the Parametric Model

Although topological and bionic optimizations have obtained a good column layout, the internal – structure size parameters still need to be optimized. Considering the assembly relationship of machine components, eight internal – structure size parameters of the column are selected for optimization, as shown in Figure 10. The initial values of these parameters are calculated by the empirical method, and their value ranges are determined by the response – surface model in ANSYS Workbench, as shown in Table 2.

| Size | Variable Description | Initial Value (mm) | Change Range (mm) |

|---|---|---|---|

| DS_L | Thickness of the main – vein – like rib plate | 10 | 9 – 11 |

| DS_W | Length of the rear cavity of the column | 135 | 130 – 140 |

| DS_P | Thickness of the secondary – vein – like rib plate | 5 | 4 – 6 |

| DS_R | Depth of the rear cavity of the column | 500 | 475 – 525 |

| DS_Y | Thickness of the banana – petiole – like rib plate | 8 | 7 – 9 |

| DS_U | Thickness of the front – cavity rib plate of the column | 10 | 9 – 11 |

| DS_I | Depth of the front – cavity of the column | 160 | 155 – 170 |

| DS_T | Thickness of the diagonal rib of the column cavity | 5 | 4 – 6 |

4.3.2 Experimental Design

To accurately establish the response – surface model, a large amount of experimental data is required. The central composite design (CCD), also known as the quadratic regression rotation design, is selected for this experiment. Based on this method, 81 groups of data – theoretical points are extracted. The input parameters are the eight internal – structure size parameters of the column, and the output parameters are the first – order natural frequency, mass, maximum stress, and deformation displacement of the column. The response values of the data – theoretical points are shown in Table 3.

| Group Number | L | P | W | R | T | Y | U | I | Mass (kg) | Displacement (mm) | Stress (MPa) | Natural Frequency (Hz) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10 | 5 | 135 | 500 | 5 | 8 | 10 | 162.5 | 1023.1 | 0.0057464 | 0.42809 | 183.75 |

| 2 | 9 | 5 | 135 | 500 | 5 | 8 | 10 | 162.5 | 1023.1 | 0.0057450 | 0.42884 | 183.76 |

| … | … | … | … | … | … | … | … | … | … | … | … | … |

4.3.3 Column Optimization Based on the MOGA Algorithm

Based on the response values of the data – theoretical points obtained from the experimental design, an optimization mathematical model is established. The mass of the column is set as the objective function, the first – order natural frequency and deformation displacement are set as constraint functions, and the eight internal – structure size parameters are set as independent variables. The optimization mathematical model is shown in equations (4) and (5).

\(f = min\left(mass\left(DS_{-}T, DS_{-}I, DS_{-}U, DS_{-}L, DS_{-}P, DS_{-}W, DS_{-}R, DS_{-}Y\right)\right)\)

\(s.t. \left\{\begin{aligned} f &\geq 184Hz \\ d &\leq 0.00576mm \\ 9mm &\leq DS_{-}L \leq 11mm \\ 130mm &\leq DS_{-}W \leq 140mm \\ 4mm &\leq DS_{-}P \leq 6mm \\ 475mm &\leq DS_{-}R \leq 525mm \\ 7mm &\leq DS_{-}Y \leq 9mm \\ 9mm &\leq DS_{-}U \leq 11mm \\ 155mm &\leq DS_{-}I \leq 170mm \\ 4mm &\leq DS_{-}T \leq 6mm \end{aligned}\right.\)

The genetic – algorithm solution is carried out through the Direct optimization module in ANSYS Workbench Design Experiment. Three groups of optimal structure sizes that meet the constraint functions and minimize the objective function are selected, as shown in Figure 11. The third – group size with the minimum objective function under the same constraints is selected for comparison with the prototype column in terms of static and dynamic performance. The comparison results are shown in Table 4.

| Column | Mass (kg) | Natural Frequency (Hz) | Deformation Displacement (mm) | Maximum Stress (MPa) |

|---|---|---|---|---|

| Prototype column | 1254.5 | 183.25 | 0.0057636 | 0.56073 |

| Bionic column | 1023.7 | 184.09 | 0.0057327 | 0.42876 |

5. Conclusion

5.1 Summary of Optimization Results

This research takes the cycloid gear forming grinding machine column as the research object and adopts a multi – stage multi – objective optimization method combining first – order topological optimization, second – order structural bionics, and third – order size optimization. The following results are obtained:

- The topological – optimization design breaks the shackles of traditional design experience and provides an optimal main – body layout for the column structure.

- The structural – bionic design, based on similarity theory, provides an excellent rib – plate structure design idea for the column body, which is more innovative than traditional rib – plate structures.