0 Introduction

Gear transmission is widely used in power transmission because of its advantages of high transmission efficiency and accurate transmission ratio. Compared with helical gears, bevel gears and worm gears, spur cylindrical gears have simple structure and easy processing. Therefore, it is more widely used in all gear transmission types. When the coincidence interval is designed to be 1<ε<2, it means that the number of pairs of teeth participating in meshing during gear meshing changes from moment to time (single pair meshing to double pair meshing to single pair meshing), resulting in the meshing stiffness

Denature, which can lead to shock, vibration and noise problems in the system. In addition, tooth shape errors and center distance errors caused by problems such as machining accuracy and assembly accuracy deviating from expectations can seriously affect gears Smoothness of the drive. Each step of gear machining accuracy often requires a lot of resources. In some gear transmission systems that do not require high precision, improve the machining accuracy to reduce the vibration and noise of the system

Often undesirable. How to achieve vibration and noise reduction without changing the original system is the common goal of researchers and manufacturers. Increasing the damping of the system can often achieve twice the effect with half the effort. According to whether the input of external energy is required, vibration and noise control party The formula is divided into active control and passive control. Commonly used active control methods include magnetorheological fluid, current fluid, vibration motor, etc. The active control method has the advantages of good control effect and frequency bandwidth, but it is attached The complexity of the system leads to high costs, reduced system reliability, and its large-scale promotion and use are also limited. The passive control method does not require external energy input, and relies on the characteristics of the damper/material itself to convert the mechanical energy of vibration into heat energy and is widely used47. In recent years, viscoelastic materials with strong damping properties have attracted the attention of scholars in the field of vibration and noise reduction, due to their unique hysteresis characteristics (the deformation of molecular chains needs to be consumed

Part of the energy), used in the noise control of mechanical systems, achieved a better control effect. Fan Rongping used three viscoelastic damping materials to apply to the inner shell of the carriage to reduce the interior noise of railway vehicles, and used psychological acoustic measurement methods to compare the front and rear of noise reduction. In order to reduce the noise caused by wheel-rail contact during the driving of high-speed trains, Mao Kunpeng et al. applied four kinds of viscoelastic damping materials to the spoke plate position of the wheel, and verified the noise reduction ability of viscoelastic damping materials through experiments. Aiming at reducing the mechanical noise of submarines, Zeng Zhaoyang et al. analyzed the noise reduction effect of viscoelastic materials of different thicknesses based on the finite element method, and proposed an optimization function that constrains the parameters of the damping layer, which provided guidance for further application. Due to the ease of use and high cost performance of viscoelastic materials, they also have good application prospects in different means of transportation such as automobiles and aircraft. On the basis of previous research, acrylates are selected as a polymer material with strong damping properties

1 Noise reduction mechanism of viscoelastic materials

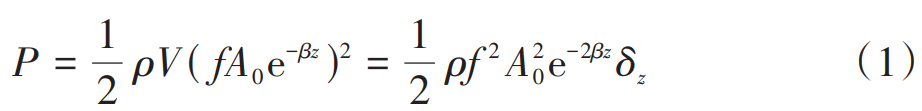

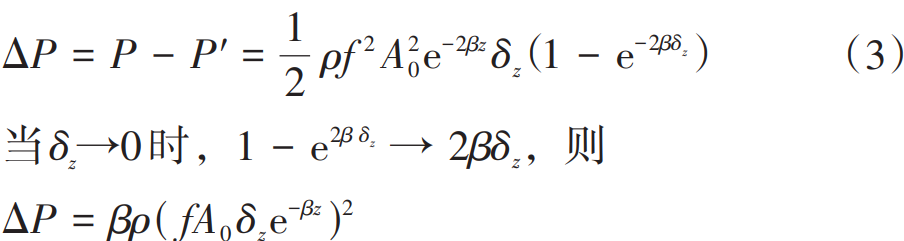

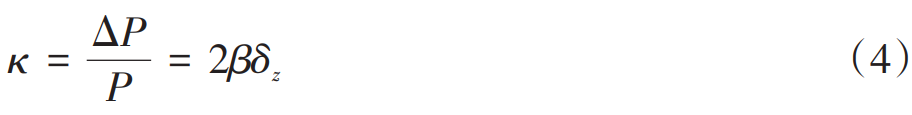

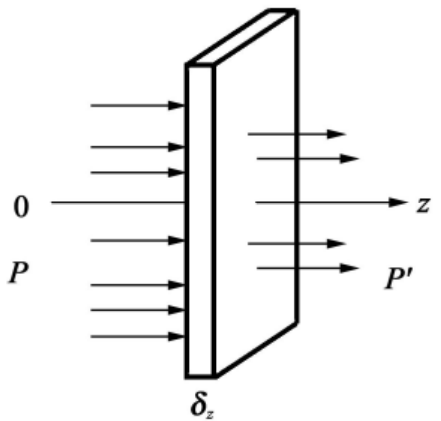

The molecular chains of viscoelastic materials are in a curled state when not subjected to external forces, and when there is energy input from the outside world, the molecular chains in the curled shape stretch, thereby consuming energy. Viscoelastic material interior The daughter chains are wound with each other, and there is considerable binding force between the molecular chains. To cause displacement between molecules, a lot of energy is consumed. Viscoelastic materials have obvious elastic hysteresis (Figure 1 shows the hysteresis curve of viscoelastic materials), and the cause of hysteresis can be attributed to the fact that the process of stretching of intertwined molecular chains after stress requires a certain amount of time buffering, and after losing force, the elasticity is restored The same is true for Cheng. This shows that the viscoelastic material has good vibration resistance and energy dissipation capacity. From a microscopic point of view, ordinary elastic materials and viscoelastic elasticity Compared with sexual materials, there is no molecular chain change characteristics, and the result of force deformation will lead to changes in the distance between the lattices, called lattice slip, that is, in the elastic range, the deformation of elastic materials hardly consumes energy. Assuming that the acoustic radiation energy propagates in the z direction in the viscoelastic material, at z=0, The amplitude of the noise is A0, and the amplitude at z will attenuate to A0e-βz, acoustic radiation The frequency is f. Take viscoelastic materials with a unit volume and density ρ, such as As shown in Figure 2, the energy flowing into the viscoelastic material per unit volume per unit time is

where V is a unit volume.

From Figure 2, it can be deduced that the energy flowing out per unit time is

Calculate the energy absorbed by the polymer material per unit time as

The loss factor is

where β is the attenuation coefficient of the material, which is generally 1/2 of the damping coefficient of the material. It can be seen from Equation (4) that the attenuation of acoustic radiation in polymer materials is proportional to the attenuation coefficient and material thickness.

Figure 1 Hysteresis curve of viscoelastic material

Figure 2 Noise propagation in viscoelastic materials

2 Straight cylindrical gear shaft system test bench

2.1 Test bench description

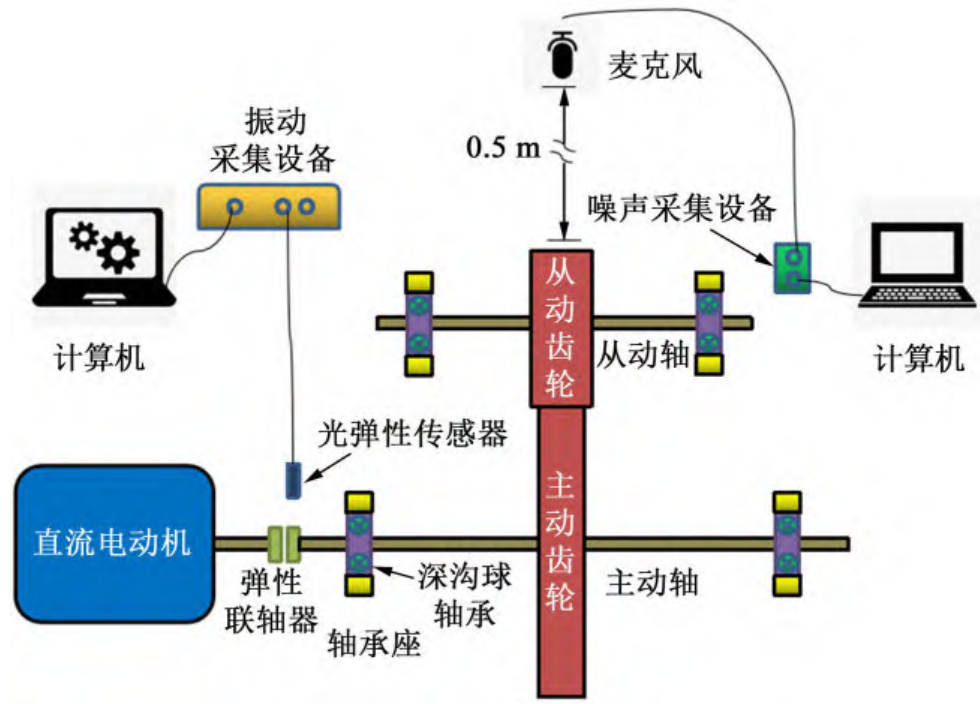

It can be seen from the literature [16] that the noise of the gear system mainly comes from axial conduction and radiation. Therefore, a spur cylindrical gear test bench was set up and two viscoelastic materials were evenly applied to the ends of spur cylindrical gears Surfaces for comparative analysis. The parameters of the spur cylindrical gear used in the test are shown in Table 1. The test bench is shown in Figure 3. During the test, different viscoelastic materials were evenly applied to the end face of the main (slave) gear, and the vibration damping effect of different materials under different working conditions was compared to verify the vibration damping effect of different materials. The test bench and the test system consist of 1. 5 kW DC motor, PulseWidth Modulation (PWM) speed control module, photoelastic sensor, vibration acquisition module, noise collection Set modules and other equipment composition. Among them, the PWM speed regulation module is used to control the speed of the DC motor, and the vibration acquisition module is connected to the photoelastic sensor to monitor the active in real time The speed of the shaft, the noise acquisition module is equipped with a microphone real-time acquisition gear Noise generated by meshing.

Table 1 Main structural parameters of spur cylindrical gears

| 结构参数 | 数值 | 结构参数 | 数值 |

| 主动轮齿数z1 | 30 | 压力角α(/ °) | 20 |

| 从动轮齿数z2 | 20 | 齿宽b/mm | 28 |

| 模数m/mm | 3 | 中心距L/mm | 75 |

Figure 3 Noise test bench for spur cylindrical gears

2.2 Results and discussion

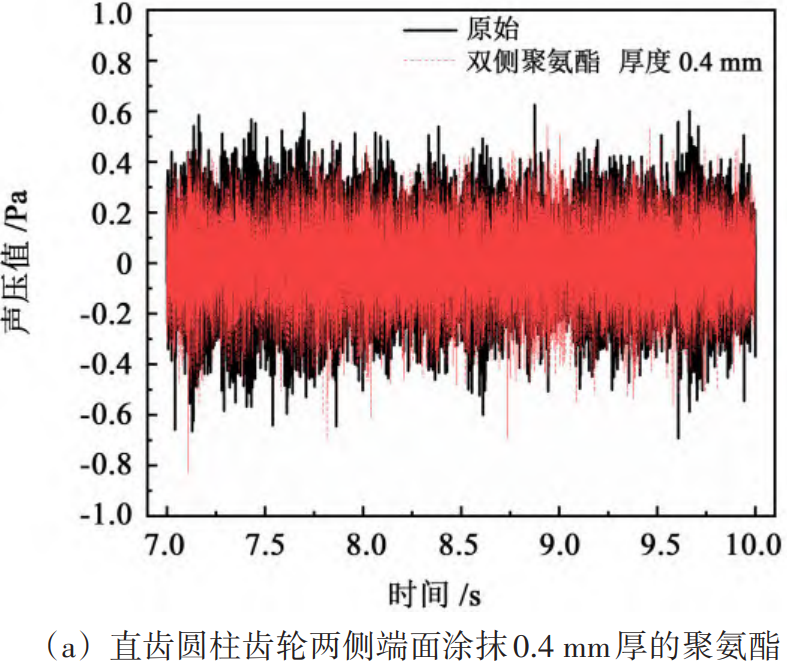

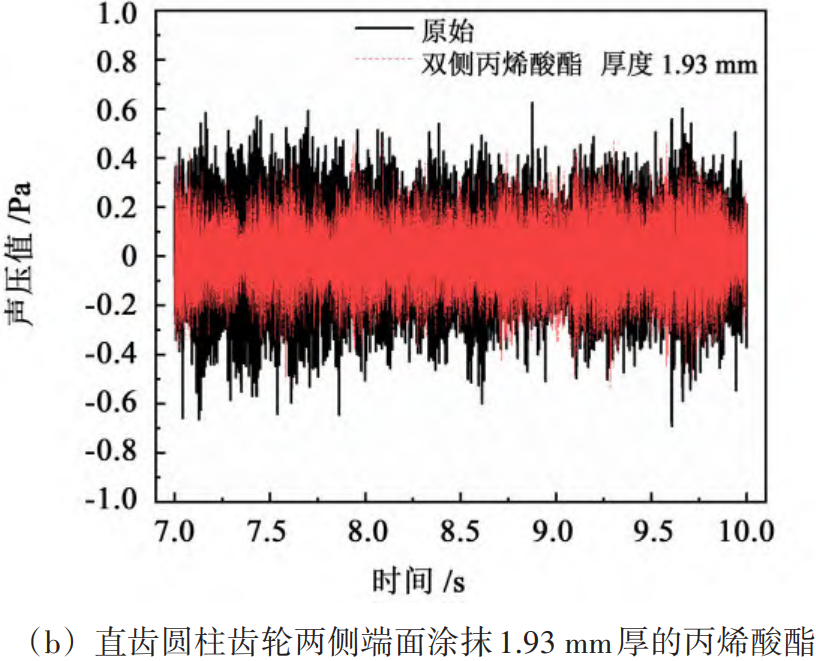

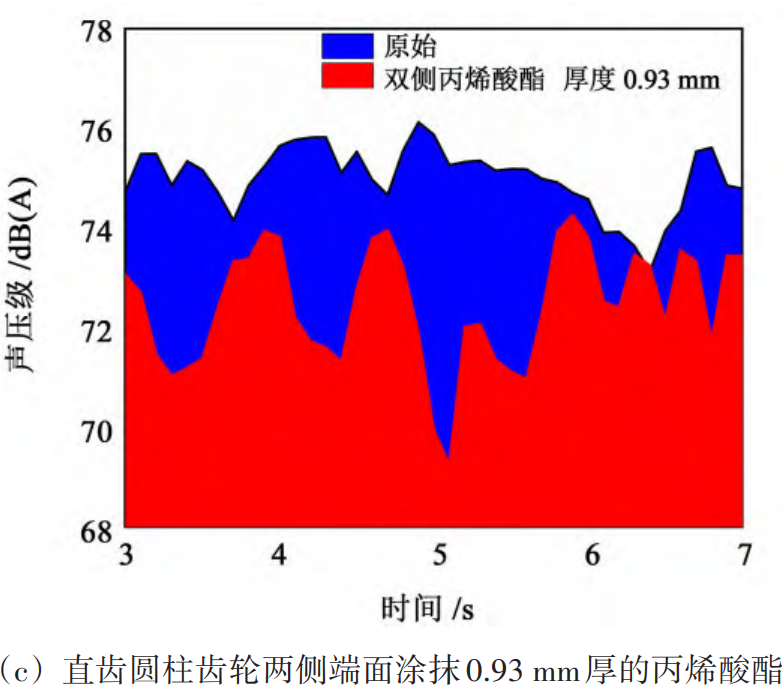

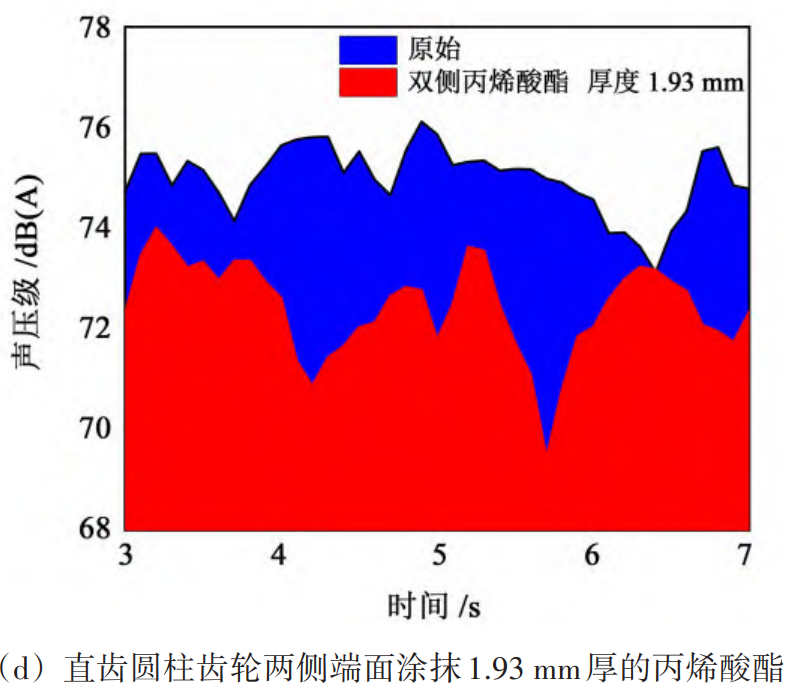

Polyurethane and acrylates are applied to the end faces of spur cylindrical gears as evenly as possible, respectively, and tested after the material solidifies and hardens. Since the spur cylindrical gears selected for the test were a pair of gears with flank wear (non-uniform wear) faults, they had a speed of more than 1 000 r/min When meshing, the noise is too loud [>100 dB(A)] to be tested. cause In this case, the test rotation speed is selected as 120 r/min, 240 r/min, 360 r/min, 480 r/min, 600 r/min and 720 r/min. Analytical test The results show that the noise of the pair of spur cylindrical gears does not exceed 70 dB(A) when meshing at 720 r/min and below. According to GB 12348-2008, when the ambient noise is above 70 dB(A), it will interfere with the conversation, resulting in upset, lack of concentration, affecting work efficiency, and even accidents. Based on the above two points, this article selects 720 r/min (conversion fr=12 Hz, meshing frequency fm=360 Hz) is the test speed, and the noise reduction test under different material types and different material thicknesses is carried out. In order to verify the long-lasting and uniform noise reduction ability of the two viscoelastic materials, the test data after long-term operation were collected for analysis. Due to the large amount of data collected, the experimental data of 3 s after stabilization were intercepted for comparison, as shown in Figure 4.

Figure 4 Sound pressure value time domain waveform

Comparing with test data without coating any material, it can be found that both materials can effectively absorb some of the noise. And with smearing 0. 4 mm polyurethane compared to 1. 93 mm thick C

The sound absorption effect of enoesters is remarkable. , the test results in Figure 4(b) are in good agreement with the theoretical derivation in Section 1, that is, as the thickness of the material increases, so does the energy consumed.The comparison of data in the time domain proves that the two materials have stable noise reduction capabilities. In order to further investigate the sensitivity of the material to frequency, a rapid Fourier transform was performed on the test data to convert the test data to

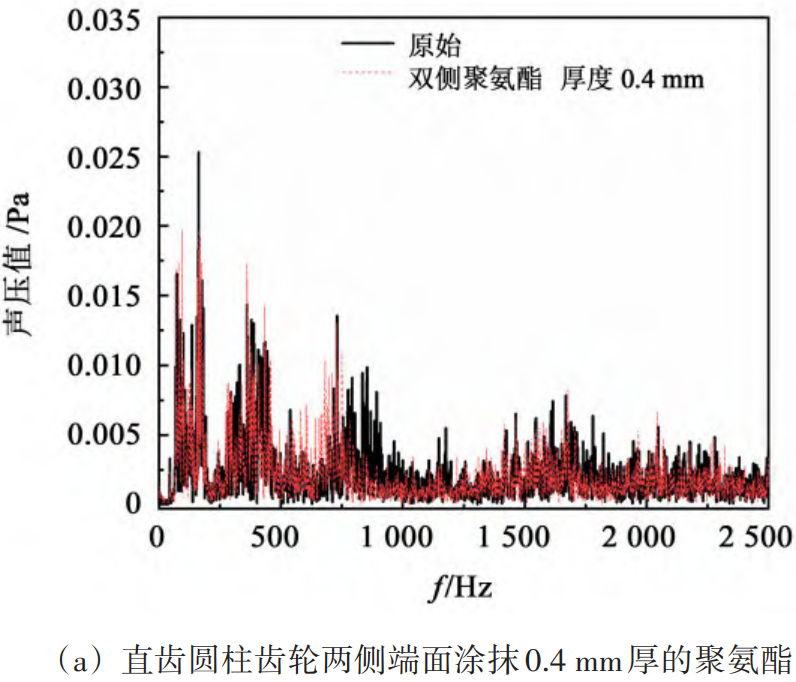

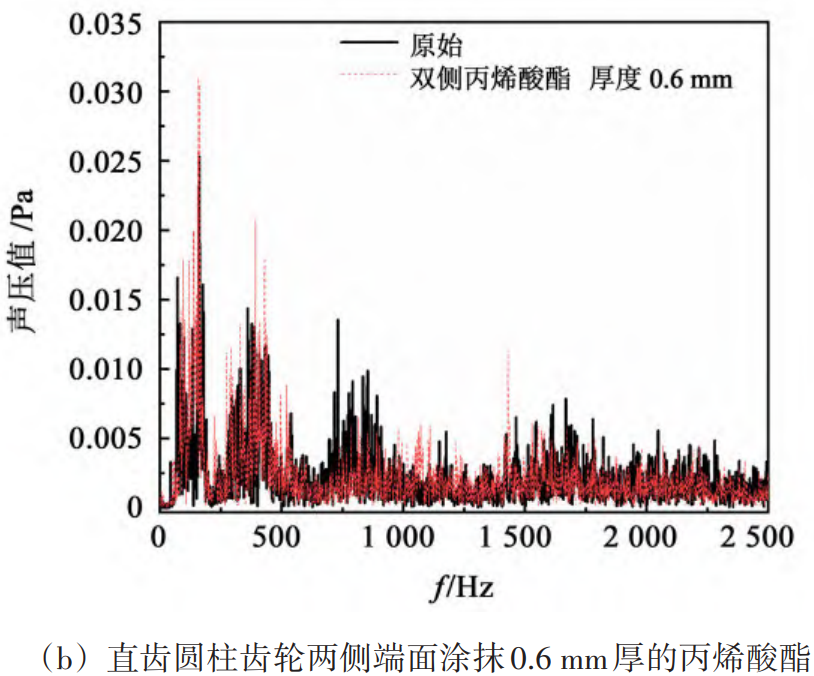

Comparative analysis was carried out in the frequency domain, and the test results are shown in Figure 5. It can be seen from Figure 5 (a) and Figure 5 (b) that when the thickness of the coating material is small, the noise (long-wave noise) absorption capacity of the low frequency band (20~200 Hz) is poor. This can be explained by the characteristics of sound wave propagation in the air, that is, long-wave noise has strong penetration and slow decreasing Dot. Therefore, when the thickness of the material is insufficient, the sound wave can easily penetrate the material and propagate to the outside world. Combined with its frequency characteristics and the analysis of unevenness on the surface after curing of the material, it can be seen that this unevenness directly leads to the increase of the amount of imbalance, resulting in the increase of sound pressure amplitude at multi-octave frequency with frequency conversion as the fundamental frequency and multi-octave frequency on the spectrogram. Due to the long curing time of polyurethane (> 24 h, 25 °C), and propylene The curing time of the ester is short (3~4 h, 25 °C), therefore, it continues to be straight The toothed cylindrical gear end face is coated with acrylate, and its watch is kept as much as possible The flatness of the surface, further test, the results are shown in Figure 5(c), Figure 5(d), respectively. The contrast application thickness is 0. 93 mm and 1. The test results of 93 mm acrylate material show that the increase of material thickness has a significant inhibitory effect on the noise in the low frequency band. According to the mechanism of noise source generated when the gear is working, the main noise source in the meshing process of light-load spur cylindrical gear comes from frequency conversion, frequency doubling of frequency conversion, meshing frequency and frequency doubling of meshing frequency. These frequencies are also often of interest to researchers working on gear vibration and noise. Therefore, the frequencies are 72 Hz (6fr) and 84 Hz (7fr)、 156 Hz(13fr), 180 Hz (15fr or 0. 5fm)、360 Hz(fm)、720 Hz(2fm)、1 440 Hz(120fr

, 4fm) and 1 668 Hz (139fr)Comparing the sound pressure values, the above frequencies are also larger in the spectrogram. The results are shown in Figure 6. Combine Figure 5 and Figure 6 can be inferred that there is a relatively obvious imbalance in the original system, resulting in an increase in the amplitude of sound pressure at the frequency multiplier of the system. Analyze the causes of this phenomenon

Based on the above analysis, it can be seen that the materials selected for the test can effectively absorb noise from frequencies such as frequency conversion, frequency doubling of frequency conversion, meshing frequency and frequency doubling of meshing frequency. To make the results of the study easier

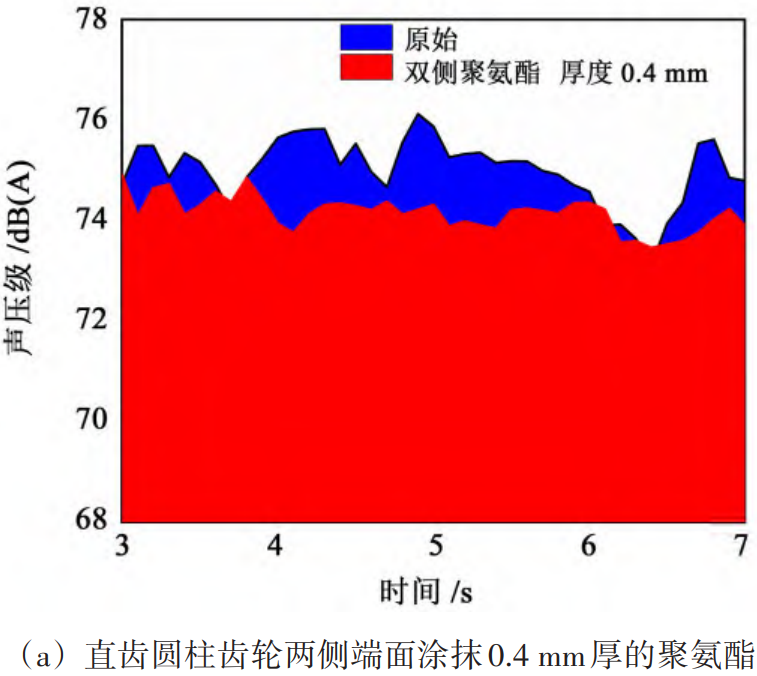

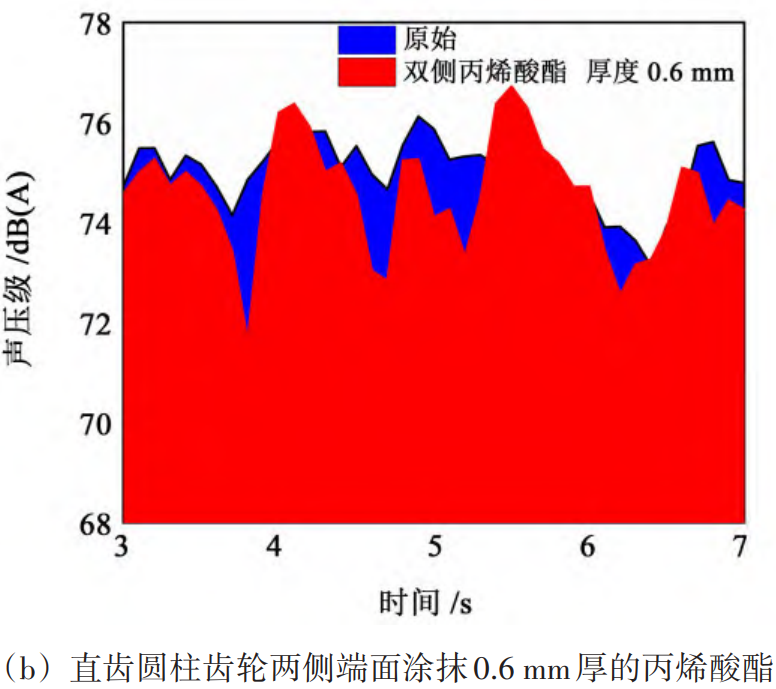

The results are understood, accepted, and disseminated, converted into sound pressure levels, and weighted average processing and comparison of sound pressure level data is shown in Figure 7. Analysis of Figure 7 shows that when the application thickness is small, the noise reduction ability of polyurethane is more stable, and the noise reduction capacity produced by acrylates is about 1 times that of polyurethane. As the thickness of the acrylate application increases, the stability and amplitude of its noise reduction increase. Contrast 0. 93 mm thickness and 1. The test results of 93 mm thickness show that when the application thickness of the acrylate increases to a certain value, the increase in thickness has little effect on the noise reduction amplitude. This may be due to insufficient bond strength between acrylate and straight cylindrical gear end faces, and noise energy cannot be effectively absorbed by the material49.

Figure 5 Comparison of sound pressure values at different frequencies

Figure 7 Comparison of sound pressure levels at different frequencies

3 Conclusion

In order to reduce the radiation and conduction noise of the end face of spur cylindrical gear, a straight cylindrical gear test bench was built, and two polymer materials (polyurethane and acrylate) were applied to the end face of the spur cylindrical gear, and the test results of different coating materials and coating thickness were compared, and the following conclusions were obtained:

1) Both materials used can effectively absorb part of the noise, and when the thickness of the coating material is small, the suppression effect on the noise of the medium and high frequency bands (200~2 500 Hz) is more obvious. Contrast the application thickness is 0. 4 mm polyurethane and coating thickness of 1. The test results of 93 mm acrylate showed that the sound absorption ability of the latter was significantly enhanced, which showed good consistency with the theoretical derivation results.

2) When the materials selected for the test reach a certain thickness, they can effectively absorb noise from common frequencies in spur cylindrical gear shaft systems, including frequency conversion, frequency doubling of frequency conversion, and meshing frequency and multiplication of the meshing frequency.

3) When the application thickness is small, the noise reduction ability of polyurethane is more stable, and the noise reduction ability produced by acrylates is about 1 times that of polyurethane. Contrast 0. 93 mm thickness and 1. The test results of 93 mm thickness show that when the application thickness of the acrylate increases to a certain value, the increase in thickness has little effect on the noise reduction amplitude. This phenomenon may be due to the bond strength of the acrylate and the end face of the straight cylindrical gear Foot caused.