Spiral bevel gear is an important part of high-precision equipment. Spiral gear is generally processed by spiral milling machine. Because the production of spiral bevel gears with different specifications requires different molds, the manufacturing cost of single piece and small batch production is very high, and the production cycle is long. Enterprises can not adapt to the transformation to single piece and small batch production mode. To solve this problem, this paper uses reverse engineering to reconstruct the three-dimensional model of spiral bevel gear, and makes secondary innovation on the basis of the original spiral bevel gear. Compared with traditional processing methods, reverse modeling not only shortens the development cycle and reduces the cost, but also makes enterprises better adapt to the requirements of single piece, small batch and multi variety production mode, and enhance the competitiveness of enterprises.

Reverse Engineering (RE), also known as reverse engineering, is a technology related to obtaining product data models from physical samples and manufacturing new products. At present, reverse engineering technology has been widely used in product replication, imitation, improvement and innovative design. It is an important technical means to digest and absorb advanced technology and shorten the product design and development cycle. In addition to being widely used in traditional fields such as molds, machinery, automobiles, motorcycles, household appliances and toys, modern reverse engineering technology also has great practical value in medicine, cultural relics, multimedia, animation, imitation of works of art and repair of damaged parts.

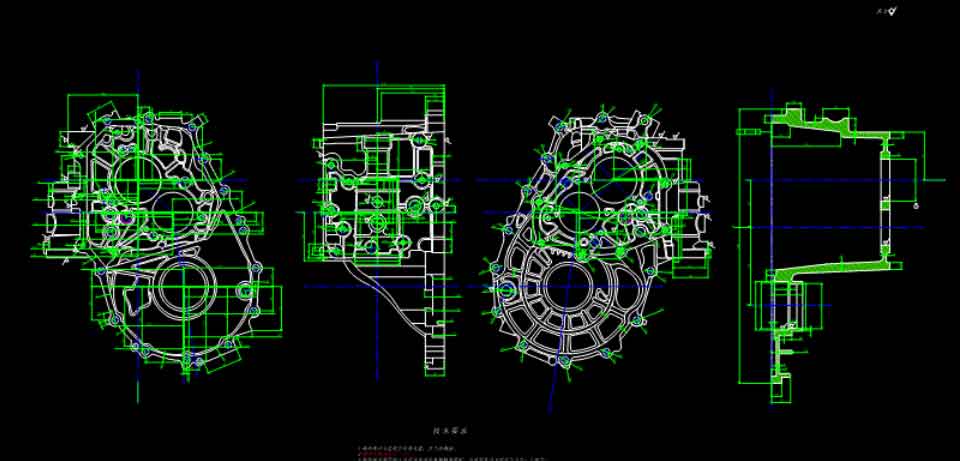

The reverse modeling of spiral bevel gear is adopted. The methods are as follows: firstly, the scanner is used to collect the data of spiral bevel gear, and then the Geomagic studio and Imageware software are used to process the collected data. Finally, the model of spiral bevel gear is reconstructed according to the processed data, so as to realize the reverse modeling of spiral bevel gear. Reverse modeling process of spiral bevel gear.