In order to analyze the hypoid gear alignment, an accurate geometric model must be established to lay a foundation for the following analysis. At the same time, the influence of various errors on hypoid gear transmission is analyzed by applying various loads and moments at different assembly error positions, simulating the actual working conditions, and the analysis conclusion is verified by experiments. The dynamic performance of hypoid gears is also analyzed, and various modal parameters are obtained.

The research contents mainly include the following aspects:

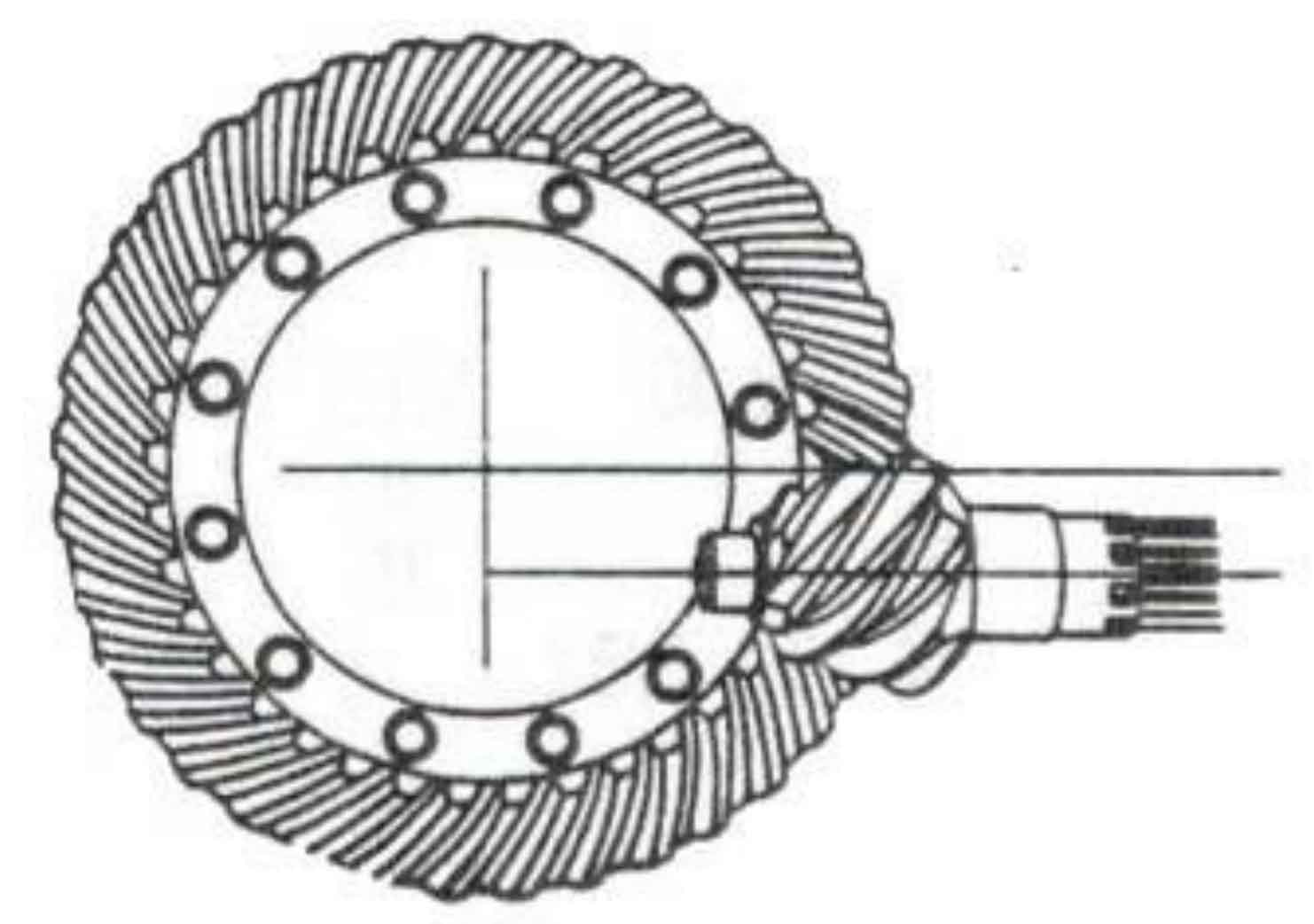

- Establish the three-dimensional solid model of hypoid gear. According to the design requirements of the drawings, the three-dimensional solid model of the hypoid gear is established, and the virtual assembly, interference inspection and analysis of the hypoid gear are carried out.

- The vibration test system of the main reducer of the rear axle of the micro car is used to test the natural frequency of the hypoid gear and calculate the characteristic frequency of the fault vibration of each component. The response of components related to the reducer to vibration is studied, and the characteristics and influencing factors of the main reducer are analyzed.

- Carry out modal analysis of hypoid gears, analyze the natural frequencies and vibration modes of each hypoid gear, get the dynamic performance of the system, put forward suggestions for structural design and improvement, and compare and analyze with the test results.

- Carry out the static meshing analysis of hypoid gear, and analyze the change of tooth surface contact stress under the condition of center distance error of hypoid gear. Various factors affecting the contact area of hypoid gears are discussed.