This paper takes a certain aero-engine spiral bevel gear box as the research object and proposes a set of methods for system-level modal analysis of bevel gears. Firstly, a 3D model of the spiral bevel gear pair with accurate tooth surface is obtained based on the design parameters and processing parameters, and static analysis is carried out on the gear system to determine the normal contact of the gear pair. Then, prestressed modal analysis is conducted to obtain the mode of the gear system, and the results are compared with the experimental results to judge the accuracy and effectiveness of the calculation method. Finally, according to the engineering practice, the influence of different contact surfaces and different loads on the system mode is analyzed. The results show that the prestressed modal analysis method based on the accurate tooth surface can be used for the system-level modal prediction of bevel gears; the system mode is more sensitive to the contact surface and relatively less sensitive to the load. Within a certain range, the influence of the load can be ignored, but the modal analysis of different contact tooth surfaces needs to be carried out respectively.

1. Introduction

Spiral bevel gears have the advantages of high contact ratio, strong load-carrying capacity, low vibration, small noise, and high tooth strength [1-5], and are widely used in the transmission of crossed-axis motion and power in the aerospace and vehicle industries. However, in the process of bevel gear transmission, abnormal vibrations may occur due to the influence of internal and external excitations, resulting in excessive amplitudes and even serious failures. Therefore, it is very necessary to study the vibration mechanism of the spiral bevel gear system to determine the cause of resonance. This requires effective modeling of the spiral bevel gear test piece and analysis of its modal characteristics, so as to further reduce vibration and avoid vibration by adjusting the structure.

At present, the modal analysis research of gear systems mainly focuses on spur gears and helical gears, while there are relatively few literatures on the modal analysis of bevel gears. The bevel gear was first designed by the American Gleason Company, and through the research of Litvin [6-11] et al., the simulation analysis has experienced a change from Tooth Contact Analysis (TCA) to Loaded Tooth Contact Analysis (LTCA), which is of great significance for shortening the production cycle, reducing the test cost, and designing high-quality gear products. In the existing literature, the main studies on the modal analysis of bevel gears are as follows: Li Duo [12] conducted modal and resonance analysis on the driven gear of high-speed and heavy-load spiral bevel gears based on the resonance theory; Xiong Renyan [13] conducted modal analysis on a certain spiral bevel gear, obtained the natural frequencies and vibration modes of each order of the gear, and verified that there would be no resonance in the high-speed gear system; Carmignani et al. [14] studied the traveling wave vibration characteristics of bevel gears by using numerical simulation methods, simulated and calculated the established finite element model of bevel gears, and obtained the natural frequencies and modal shapes of bevel gears through modal analysis; Wang Dayong [15] simulated the normal meshing state of gears based on Abaqus and analyzed the problem of gear traveling wave resonance. However, the above literature either only analyzes the modal of a single spiral bevel gear, or connects the meshing effect of the gear pair in a binding way, or is based on the theoretical simulation tooth surface, which has a large gap with the actual tooth surface, and its calculation results have a large discrepancy from the actual situation of the experiment.

This paper takes a certain aero-engine spiral bevel gear box as the research object and proposes a set of methods for system-level modal analysis of bevel gears. The main contents include four aspects: 1. Obtain a 3D model of the spiral bevel gear pair with accurate tooth surface based on the design parameters and processing parameters. 2. Conduct static analysis on the gear system to determine the normal contact of the gear pair; conduct prestressed modal analysis to obtain the mode of the gear system. 3. Compare with the test results to judge the accuracy and effectiveness of the calculation method. 4. Analyze the influence of different contact surfaces and different loads on the system mode.

2. Accurate Modeling of Spiral Bevel Gear

2.1 Obtaining Tooth Point Information

The formation of the tooth surface of a bevel gear is the result of the combined action of design parameters and processing parameters. When modeling the tooth surface of a bevel gear, accurate tooth point information is required. Tooth point information is mainly obtained through two methods: obtained by processing parameter simulation or by using a coordinate measuring machine to sample points on the tooth surface. Without considering the processing error, the tooth point information obtained by these two methods is consistent. In this paper, processing parameter simulation is adopted. The specific method is as follows: Based on the gear design parameters (Table 1) and processing parameters (Table 2), import them into the Masta software. After completing the macro parameter modeling, input the processing parameters shown in Table 2 in the manufacturing module of the spiral bevel gear to establish the accurate tooth surface, and then output the tooth point information of 7×9. Figure 2 shows the schematic diagram of the processing parameters of the large wheel in Masta and the tooth point information of 1×9. According to the modeling needs, a tooth point set and a tooth root dot set are established.

2.2 3D Modeling of Gear Pair

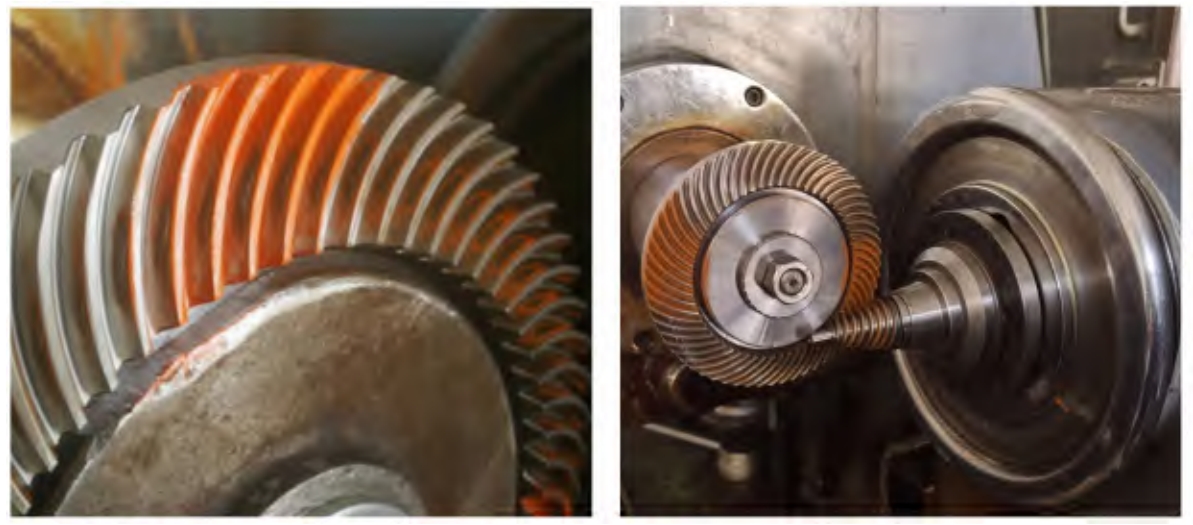

After obtaining the tooth point information, import it into Catia for 3D finite element modeling. The specific modeling process is as follows: Import the tooth point parameters, establish spline curves, create a mesh surface, establish a tooth blank, perform operations such as segmentation array, and then obtain a gear model with an accurate tooth surface, as shown in Figure 3.

Establish a complete gear shaft model and assemble it to obtain a complete gear pair analysis model, as shown in Figure 4. Among them, the material of all gear shafts is 9310 steel, the elastic modulus is 204 GPa, the density is 7850 kg/m³, and the Poisson’s ratio is 0.293.

2.3 3D Modeling of Gear System

After completing the modeling of the gear pair, it is also necessary to introduce stiffness support to the bearing support surface, as shown in Figure 5. Among them, it is difficult to achieve complete consistency between the tooling stiffness and the actual support stiffness, but it can ensure consistency in the order of magnitude. In order to compare with the test, the tooling stiffness is used for calculation in the simulation, and the stiffness values are shown in Table 3. Set friction contact for the contact surface of the gear pair, and the friction factor is 0.1.

3. Modal Analysis

Modal analysis cannot consider nonlinear factors such as friction contact, and the binding constraint method has a large difference from the actual gear tooth coupling form. Therefore, the calculation method of prestressed modal is adopted in this paper, that is, first conduct static strength analysis, and then conduct prestressed modal calculation on the gear system.

3.1 Static Strength Analysis

When calculating the static strength, in order to facilitate comparison with the test, the small wheel convex surface drives the large wheel concave surface, a torque of 100 N·m is applied to the driving wheel, and the rotation of the driven wheel is constrained to analyze the contact situation of the gear pair. The contact impression and stress nephogram of the gear pair obtained by calculation are shown in Figures 6 and 7 respectively. It can be seen from Figures 6 and 7 that the gear pair is in normal contact, with two pairs of teeth participating in the contact, and the maximum stress value is 275.14 MPa.

3.2 Prestressed Modal

Taking the static strength calculation results as the initial conditions, the mode of the system within 22 kHz can be calculated. The selected typical modes are shown in Table 4. It can be seen from Table 4 that, different from the modal analysis results of a single gear shaft, the prestressed modal analysis results show that the number of nodal diameter vibration modes increases, and one to four nodal diameter vibration modes all correspond to multiple modal frequencies. Due to the influence of contact, even a special coupled vibration mode in the form of a nodal diameter coupled umbrella shape (order 12) appears. Some vibration mode diagrams are listed in Section 4.3.

4. Experimental Verification

4.1 Experimental Arrangement

The test fixture is designed to replace the support of the case and bearings, and the stiffness values are shown in Table 3. The test piece of the modal test is shown in Figure 8. Use the loading rod to apply a torque of 100 N·m to ensure the meshing of the gear pair, then lock it with the fixture and the anti-rotation key, remove the loading rod for the modal test, as shown in Figure 9. During the test, the mobile force hammer method is used for testing based on the LMS software, that is, single-point excitation and multi-point response, and the process is shown in Figure 10. The layout of the hammering points is shown in Figure 11, among which the hammering points 4 and 7 of the driving wheel and the hammering points 3 and 24 of the driven wheel are the pasting positions of the sensor. During the test, the bending vibration mode is mainly concerned for the gear shaft, and the hammering direction is set to the radial direction; the nodal diameter vibration mode is mainly concerned for the gear tooth surface, and the hammering direction is set to the axial direction, and the vibration modes below the fifth nodal diameter are mainly concerned. Comprehensively considering the test requirements and the operability of the hammering points, 10 hammering points are evenly arranged. The final geometric model in LMS is shown in Figure 12.

4.2 Experimental Data Analysis

The method of curve fitting is used to extract the modal parameters, and the optimal estimation of the natural frequency, damping and vibration mode is obtained based on the least square estimation. The stable modes of the extracted frequency damping and vibration mode vectors are shown in Table 5, and the typical vibration modes are listed in Section 4.3.

4.3 Simulation and Experimental Comparison

By combining Table 4 and Table 5 and comparing the simulation calculation results with the test results, it is found that the simulation calculation results and the measured modes do not have one-to-one correspondence. The reasons are as follows: 1. Due to the influence of the fixture during the test, the vibration modes related to or coupled with the fixture appear. 2. Due to human factors or conditions, some modes are not excited.

This paper mainly compares the vibration modes of the gear pair and ignores the influence of the fixture on the bending vibration mode. The results are shown in Table 6 and Figure 14. It can be seen from this that, except for the first nodal diameter vibration mode of the driving wheel, the simulation calculation results are larger than the measured values. From the perspective of the vibration mode, the measured vibration mode of the first nodal diameter is obviously coupled with bending, and the correspondence with the simulation results is not strong; the other vibration modes are less affected by bending, and the errors are all less than 10.08%. Considering that the modal calculation margin in engineering is about 10%, the theoretical calculation results can be used to support the test.

5. Modal Sensitivity Analysis

In view of the fact that the concave and convex surfaces of the aerospace bevel gears are working surfaces in engineering, and the load is not constant, it is necessary to analyze the influence of the contact surface and the load on the mode to determine whether it is necessary to conduct multi-condition analysis in the actual analysis. The analysis is carried out for the four groups of working conditions shown in Table 7, among which Group 3 is the reference benchmark.

5.1 Influence of Different Contact Surfaces on Prestressed Modal

Combining Group 1 and Group 3, analyze the mode of the gear system under the condition of only different contact surfaces, and the vibration mode selection is basically the same as that in Table 4, and the natural frequency error is shown in Table 8. It can be seen from Table 8 that after changing the contact surface, the system mode changes, among which most of the modes show the same vibration mode, and the natural frequency error does not exceed 3%, but some vibration mode shapes change. The listed vibration mode diagrams are shown in Figure 15, and new vibration modes (order 11) and new forms of coupled vibration modes (order 7 and order 19) appear. Therefore, when conducting simulation predictions for the test, it is necessary to conduct modal analysis for different contact surfaces respectively.

5.2 Influence of Different Loads on Prestressed Modal

Combining Group 2, Group 3 and Group 4, analyze the mode of the gear system under the condition of only different loads, and the vibration mode selection is basically the same as that in Table 4, and the error is shown in Table 9. It can be seen from Table 9 that after changing the load, the change of the system mode only appears in the change of frequency, and the vibration mode remains the same. Among them, the greater the load, the higher the natural frequency under the same vibration mode, but the error value does not exceed 2.5%. Therefore, when conducting simulation predictions for the test, within a certain load range, the influence of the load on the modal of the bevel gear system can be ignored.

6. Conclusions

(1) Taking a certain aero-engine spiral bevel gear box as the research object, a 3D model of the spiral bevel gear pair with accurate tooth surface is obtained based on the design parameters and processing parameters, and a set of methods for system-level modal analysis of bevel gears is proposed.

(2) By comparing the simulation calculation mode with the test results, the gear pair vibration mode dominated by the nodal diameter type and its coupled vibration mode has an error of less than 10.08% with the test, which verifies the accuracy and effectiveness of the calculation method.

(3) The results show that the modal of the bevel gear system is more sensitive to the contact surface and relatively less sensitive to the load. The reason is that different contact surfaces represent completely different meshing states, and the meshing stiffness values may have differences in orders of magnitude, while the change of the meshing state caused by the load only appears in the size of the stressed surface, and the influence on the meshing stiffness will not cross orders of magnitude. Therefore, within a certain range, the influence of the load can be ignored, but the modal analysis of different contact tooth surfaces needs to be carried out respectively.

7. References

[1] Tang Dingguo, Chen Guomin. Recent situation and prospect of gear technology[J]. Journal of Mechanical Engineering, 1993, 29(5): 35-42.

8. Appendix

Table 1: Design Parameters

| Parameters | Small Wheel | Large Wheel |

|---|---|---|

| Tooth Number | 35 | 37 |

| Module/mm | – | – |

| Midpoint Helix Angle/(°) | – | – |

| Normal Pressure Angle/(°) | – | – |

| Shaft Crossing Angle/(°) | 80 | – |

| Tooth Width/mm | 24 | – |

| Rotation Direction | Right-handed | Left-handed |

| Outer Cone Distance/mm | 89.634 | – |

| Pitch Cone Angle/(°) | 38.6648 | 41.3352 |

| Face Cone Angle/(°) | 40.859 | 43.3855 |

| Root Cone Angle/(°) | 36.6145 | 39.141 |

| Tooth Root Height/mm | 3.434 | 3.209 |

| Tooth Tip Height/mm | 2.607 | 2.833 |

Table 2: Machining Parameters

| Parameters | Large Wheel | Small Wheel Concave Surface | Small Wheel Convex Surface |

|---|---|---|---|

| Blank Swing Angle of Wheel/(°) | 61.7443 | 61.5715 | 60.265 |

| Offset Distance/mm | 0 | 0 | 0 |

| Distance from the Center of the Machine Tool to the Workpiece Mounting Datum/mm | 0 | 7.81848 | -5.42884 |

| Blank Mounting Angle/(°) | 39.3737 | 36.62 | 36.62 |

| Second-order Degeneration Coefficient | -0.0129735 | 0.047363 | -0.067056 |

| Third-order Degeneration Coefficient | 0.0179555 | 0.0240835 | 0.0006225 |

| Cutter Disk Radius/mm | 70.30805 | 74.78439 | 68.1639 |

| Rolling Ratio | 1.478227 | 1.709616 | 1.507862 |

| Slide/mm | -0.21505 | -4.66347 | 3.23934 |

| Cutter Rotation Angle/(°) | 206.44 | 25.5 | 27 |

| Cutter Inclination Angle/(°) | -0.0561 | 0 | 0 |

| Inner Cutting Edge Angle/(°) | 22.5016 | – | 21.45 |

| Inner Tip Radius of Cutter/mm | 0.7 | – | 74.676 |

| Outer Cutting Edge Angle/(°) | 20.8422 | 19.5 | – |

| Outer Tip Radius of Cutter/mm | 0.7 | 79.121 | – |

| Cutter Top Width/mm | 1.36 | – | – |

| Radius R/mm | 76.2 | – | – |