1. Introduction

The development of high – speed rail has revolutionized modern transportation, with standard multiple unit trains playing a crucial role. The gearbox is a vital component in these trains, and the assembly process of its small gear shaft significantly impacts the overall performance and reliability of the train. This research focuses on the G321 – type gearbox used in CR400AF multiple units, aiming to address the issue of unstable bearing clearances in small gear shafts during assembly and running – in processes.

1.1 Gearbox Structure and Assembly Requirements

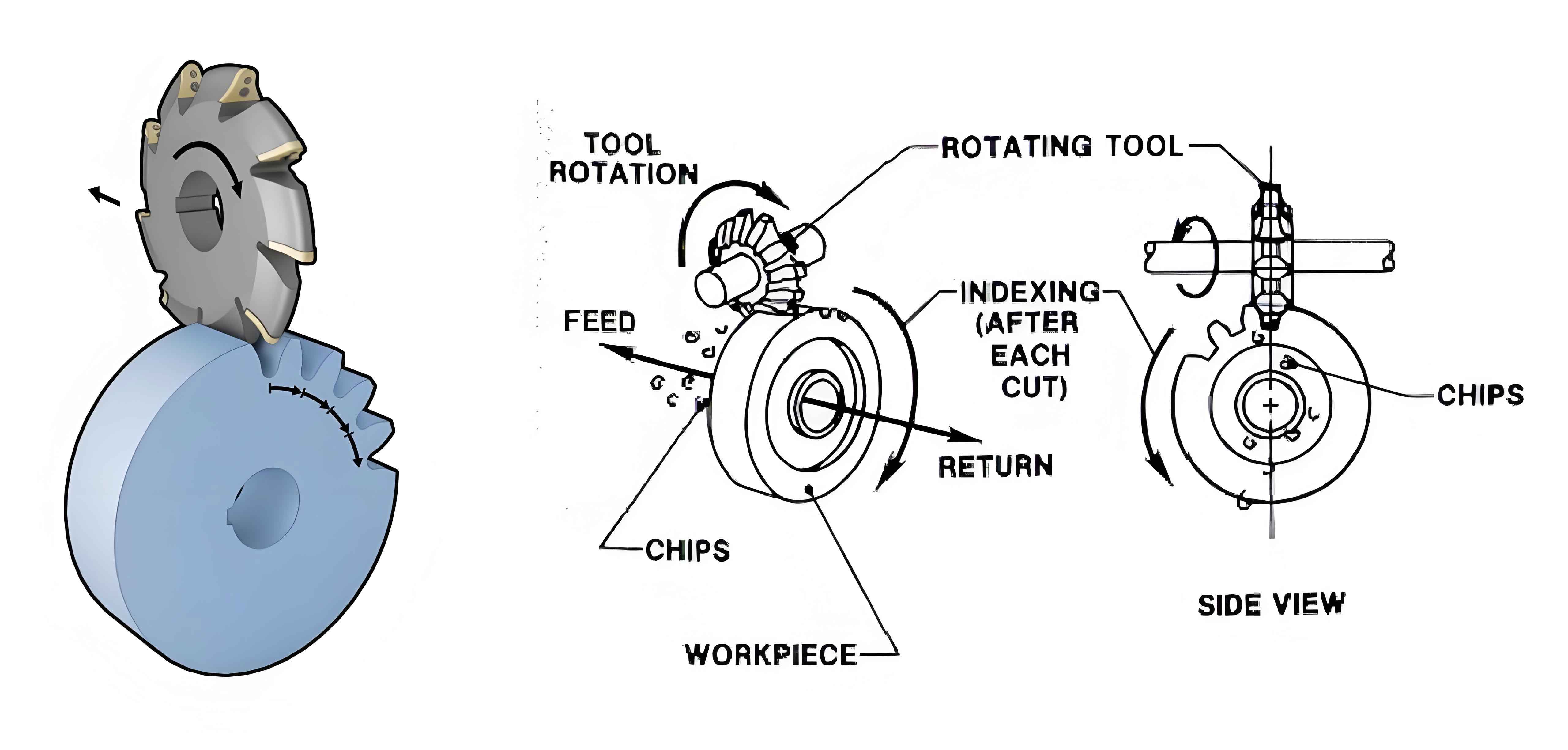

The G321 – type gearbox has a complex structure (as shown in Figure 1). The motor – side (PM side) of the small gear shaft is equipped with a cylindrical roller bearing that withstands radial loads. The wheel – side (PW side) combines a cylindrical roller bearing and a four – point contact ball bearing. The cylindrical roller bearing on the PW side also bears radial loads and is installed in the bearing seat with an interference fit. The four – point contact ball bearing on the PW side withstands axial loads and has a clearance fit with the inner ring of the bearing seat. Its inner ring is fixed by the small gear shaft gland, and the outer ring is fixed by the sealing cover.

| Component | Function | Installation Method |

|---|---|---|

| PM – side Cylindrical Roller Bearing | Bear radial loads | – |

| PW – side Cylindrical Roller Bearing | Bear radial loads | Interference fit with bearing seat |

| PW – side Four – Point Contact Ball Bearing | Bear axial loads | Clearance fit with inner ring of bearing seat; inner ring fixed by small gear shaft gland, outer ring fixed by sealing cover |

During the high – level maintenance of standard multiple unit trains (which includes a sequence of Level 3, Level 4, Level 3, and Level 5 maintenance, with the fault in this study occurring during Level 4 maintenance), the gearbox is disassembled to its smallest components. Components such as the large and small gear shafts, bearings, bearing covers, and seals are inspected and replaced as necessary. After reassembly, the bearing clearances of the large and small gear shafts and the tooth clearances of the gears need to be measured. The clearance of the small gear shaft after assembly should be a stable value, and the difference between the clearance measured after assembly and that measured after the running – in test should be small and within the standard range.

1.2 Problem Statement

In the actual maintenance process, it has been observed that the bearing clearances of small gear shafts are unstable. For example, in the cases of M2 car 1 – axis, M2 car 4 – axis, and M3 car 1 – axis during Level 4 maintenance, the measured clearances of the small gear shafts after assembly and running – in tests showed inconsistent results, some being qualified after assembly but unqualified after running – in, and vice versa. These issues have raised concerns about the quality and reliability of the gearbox assembly, highlighting the need for in – depth research to identify the influencing factors and develop solutions.

2. Assembly Process of Small Gear Shafts

2.1 工艺流程 (Process Flow)

The assembly process of small gear shafts involves multiple steps, as detailed in Table 1. Each step is crucial and requires strict control to ensure the proper functioning of the gearbox.

| Step Number | Operation Content |

|---|---|

| 1 | Measure the dimensions of all components |

| 2 | Heat – install the outer ring of the PM – side bearing |

| 3 | Heat – install the outer ring of the PW – side bearing and the outer retaining ring |

| 4 | Assemble the inner ring of the PM – side bearing and the oil – retaining ring |

| 5 | Assemble the PW – side bearing, inner retaining ring, and the B – side of the inner ring of the ball bearing |

| 6 | Assemble the PW – side ball bearing, bearing cover, and the A – side of the inner ring of the ball bearing |

| 7 | Assemble the bearing pressure plate on the PW side |

| 8 | Assemble the PW – side sealing cover |

During the assembly of the small gear shaft, it is necessary to measure four values, X, Y, P, and Q, of the bearing pressure plate and the PW – side sealing cover. These values ensure that the inner and outer rings of the ball bearing are properly pressed, and the differences between X – Y and P – Q need to meet specific requirements to ensure the normal operation of the bearing.

2.2 Key Assembly Points and Precautions

The assembly of the four – point contact ball bearing is a key step. The inner ring of the four – point contact ball bearing is in an interference fit with the small gear shaft and is assembled onto the shaft by heating expansion. The outer ring is fixed by the outer spacer ring and the sealing cover in the axial direction. Any misalignment or improper installation during this process can lead to changes in the bearing clearance. For example, if the outer ring of the four – point contact ball bearing is not installed concentrically with the inner ring, it will affect the contact angle between the rollers and the rings, thereby changing the bearing clearance.

Another important aspect is the assembly of the sealing cover. The sealing cover not only plays a role in sealing but also has an impact on the bearing clearance. When installing the sealing cover, the tightening force of the bolts can cause additional forces on the bearing components, which may affect the installation state of the bearing and ultimately the bearing clearance.

3. Fault Analysis and Hypothesis Testing

3.1 Fault Phenomena

As mentioned earlier, there are various fault phenomena related to the bearing clearances of small gear shafts. The following table summarizes the specific situations of different axes during maintenance:

| Car Axis | Maintenance Level | Bearing Replacement | Assembly – Time Clearance Status | Running – in Clearance Status | Additional Operations and Results |

|---|---|---|---|---|---|

| M2 car 1 – axis | Level 4 | New small gear – side bearings | Qualified (measured at vertical – installation position) | Unqualified (measured at horizontal – installation position) | – |

| M2 car 4 – axis | Level 4 | New small gear – side bearings | Qualified (measured at vertical – installation position) | Unqualified (measured at horizontal – installation position) | – |

| M3 car 1 – axis | Level 4 | New small gear – side bearings | Unqualified (measured at vertical – installation position) | Qualified after disassembling and reassembling the PW – side bearing gland (measured at vertical – installation position) | – |

| Gearbox (1111) | – | – | – | Unqualified (measured at horizontal – installation position) | Qualified after impacting the PW – side bearing gland and the M – side of the small gear shaft |

These phenomena indicate that the bearing clearances of small gear shafts are affected by multiple factors, and it is necessary to conduct in – depth research to determine the root causes.

3.2 Hypothesis Testing

To identify the factors affecting the bearing clearances of small gear shafts, several hypotheses were proposed and tested through experiments.

3.2.1 Research on the Difference in Measuring Small Gear Shaft Clearances at Horizontal and Vertical Installation Positions

Test Purpose: To study whether the installation position (horizontal or vertical) of the gearbox affects the measurement of small gear shaft clearances.

Test Principle: When measuring the bearing clearance at the vertical installation position, the small gear shaft’s own gravity needs to be overcome, while at the horizontal installation position, this is not the case. The impact of this difference on the bearing clearance measurement is verified.

Test Process: Two gearboxes, (0000) and (1111), were selected. The bearing clearances of the small gear shafts were measured at both the horizontal and vertical installation positions. The results are shown in the following table:

| Gearbox Number | Clearance at Horizontal Installation Position | Clearance at Vertical Installation Position |

|---|---|---|

| (0000) | A | A + 0.001 |

| (1111) | B | B – 0.001 |

Combined with the measurement results of 12 gearboxes in previous tests, it can be concluded that the horizontal and vertical installation positions of the gearbox have little impact on the bearing clearances of small gear shafts.

3.2.2 Research on the Influence of Spacer Ring Deflection on Bearing Clearance

Test Purpose: To investigate the impact of spacer ring deflection on the bearing clearance.

Test Principle: The deflection of the spacer ring can change the contact angle between the outer ring of the ball bearing and the rollers, thereby affecting the small gear shaft bearing clearance.

Test Process: The test involved several steps. First, the spacer ring was assembled with a deflection, and the gearbox was assembled and the small gear shaft clearance was measured. Then, the PW – side sealing cover was disassembled and reassembled, and the clearance was measured again. After that, the four – point contact ball bearing was removed, and the clearance between the spacer ring and the outer ring of the cylindrical bearing was checked. Finally, the four – point contact ball bearing and the gearbox were reassembled, and the clearance was measured once more. The test results for six gearboxes are shown in Table 2:

| Step | Spacer Ring State | Clearance of Gearbox 1 | Clearance of Gearbox 2 | Clearance of Gearbox 3 | Clearance of Gearbox 4 | Clearance of Gearbox 5 | Clearance of Gearbox 6 |

|---|---|---|---|---|---|---|---|

| 1 | Spacer ring installed with deflection | Unqualified | Unqualified | Unqualified | Unqualified | Unqualified | Unqualified |

| 2 | – | Qualified | Qualified | Qualified | Qualified | Qualified | Qualified |

| 3 | Spacer ring without deflection, meeting process requirements | – | – | – | – | – | – |

| 4 | – | Qualified | Qualified | Qualified | Qualified | Qualified | Qualified |

| 5 | – | Qualified | Qualified | Qualified | Qualified | Qualified | Qualified |

The test results show that the deflection of the spacer ring can affect the small gear shaft clearance, but the assembly of the PW – side sealing cover can eliminate the influence of the spacer ring deflection.

3.2.3 Research on the Relationship between the Radial Position Change of the Outer Ring of the Four – Point Contact Ball Bearing and the Bearing Clearance Change

Test Purpose: To explore the relationship between the radial position change of the outer ring of the four – point contact ball bearing and the change in bearing clearance.

Test Principle: The relative position between the outer ring of the ball bearing and the rollers can lead to different bearing contact angles, which in turn affect the bearing clearance.

Test Process: Six gearboxes were selected for this test. Different – thickness wires were inserted between the outer ring of the four – point contact ball bearing and the bearing seat, and then the small gear shaft was assembled and the clearance was measured. After that, the PW – side sealing cover was disassembled and reassembled, and the clearance was measured again. The test results are shown in Table 3:

| Serial Number | Four – Point Contact Ball Bearing Outer Ring Four – Point Height Difference (X) | X – Y | Wire Thickness/mm | First – Measured Clearance Value (A1, B1, C1 > 0) |

|---|---|---|---|---|

| 1 | Meets requirements | – | 1.2 | 0 < A1 – B1 – C1 |

| 2 | Meets requirements | Meets maintenance requirements | 0.98 | 0 < A1 – B1 |

| 3 | Meets requirements | – | 0.73 | 0 < A1 |

The test results indicate that there is a certain relationship between the clearance of the four – point contact ball bearing and the radial distribution of its outer ring. The proper position of the outer ring of the bearing is decisive for the stability of the bearing clearance.

3.2.4 Research on the Relationship between the Assembly of the Sealing Cover and the Change in Bearing Clearance

Test Purpose: To study the impact of the sealing cover assembly on the bearing clearance.

Test Principle: When installing the sealing cover, the bolts used to fasten it to the PW – side bearing seat can exert an additional external force on the outer ring, inner ring, and spacer ring of the four – point contact ball bearing, affecting the installation state of the components and thus the bearing clearance.

Test Process: Sixteen assembled and run – in gearboxes with unqualified clearances were selected. Only the new PW – side sealing cover was replaced, and the assembly clearance and the clearance after the running – in test were measured again. The results showed that the clearances of 14 gearboxes returned to normal, while those of 2 gearboxes still showed abnormal changes. This indicates that the installation of the PW – side sealing cover and its assembly relationship with the outer ring of the bearing directly affect the bearing clearance.

4. Result Analysis

4.1 Influence Mechanism of Assembly on Bearing Clearance

The assembly process of the four – point contact ball bearing has a significant impact on the bearing clearance. When the outer ring of the four – point contact ball bearing is initially installed, if it moves radially and is not concentric with the inner ring, and the displacement is too large, it will affect the bearing clearance. When the sealing cover is installed at this time, if the pressing force is sufficient, the clearance may be relatively stable but may not meet the requirements. After running – in, if the expansion force is not enough to overcome the pressure provided by the outer ring, the outer ring of the bearing cannot be self – adjusted, resulting in an unqualified running – in clearance. On the other hand, if the pressing force is insufficient, the expansion force after running – in may be sufficient to overcome the pressure of the outer ring, allowing the outer ring to self – adjust and become concentric with the inner ring, and the running – in clearance may change.

The contact angle β between the steel balls and the inner and outer rings of the bearing also affects the bearing clearance. According to the formula (although complex mathematical formulas are avoided, this formula is used for a simple explanation here), the concentricity of the outer and inner rings of the four – point contact ball bearing will cause changes in the β angle, directly affecting the bearing clearance. Therefore, ensuring the concentricity of the outer and inner rings of the bearing and the stability of the β angle is the key to guaranteeing the bearing clearance.

4.2 Importance of Assembly Quality

The above – mentioned analysis shows that the assembly quality of the small gear shaft components, especially the four – point contact ball bearing and the sealing cover, is crucial for the stability of the bearing clearance. Any defect in the assembly process, such as improper installation of the spacer ring, uneven tightening of the sealing cover bolts, or misalignment of the bearing rings, can lead to changes in the bearing clearance. This not only affects the normal operation of the gearbox but also reduces the reliability and service life of the entire train. Therefore, improving the assembly quality through optimized processes and strict quality control is essential.

5. Process Optimization

5.1 Optimization Objectives

The main objective of process optimization is to ensure that when the PW – side sealing cover is installed, the outer ring of the four – point contact ball bearing is in the optimal state, avoiding the outer ring from bearing external forces during the assembly process. This aims to improve the stability of the bearing clearance and enhance the overall quality of the gearbox assembly.

5.2 Optimization Measures

The assembly process of the sealing cover was optimized by adopting a two – step assembly and three – step tightening method. In the first step, the sealing cover is assembled without applying sealant when the small gear shaft is in the assembled state. The torque tightening process includes three sub – steps: pre – tightening (pressing the spring washer) in the first step, tightening to in the second step, and finally tightening to in the third step. After the assembly of the PW – side and PM – side bearing covers, the PW – side sealing cover is disassembled, sealant is applied, and then the sealing cover is reassembled. The torque tightening process for the reassembly is the same as the first – step assembly.

6. Effect Evaluation

6.1 Evaluation Index Selection

To evaluate the effect of the process optimization, the X value of the outer ring of the four – point contact ball bearing was selected as an important evaluation index. The X value represents the distance from the outer ring of the ball bearing to the PW bearing seat. A smaller difference in the X value around the circumference indicates that the outer ring of the four – point contact ball bearing is more concentric with the inner ring, the β angle is more stable, and the bearing clearance is more stable.

6.2 Evaluation Results

After the process optimization, the X – value analysis results are shown in Figure 7. The X – value difference around the circumference decreased significantly, from 0.010mm before optimization to 0.004mm after optimization. This indicates that the assembly quality has been significantly improved.

In addition, by comparing the changes in the small gear shaft clearances before and after assembly and running – in before and after process optimization (as shown in Figure 8 and Figure 9), it can be seen that the change range of the small gear shaft clearances before and after assembly and running – in was – 0.06 – 0.1mm before optimization, while after optimization, it was reduced to – 0.03 – 0.04mm. This clearly demonstrates that the optimized process effectively controls the bearing clearance and improves the stability of the small gear shaft bearing clearance.