This paper focuses on the research of the time-varying meshing stiffness algorithm for gears with cracks, especially for gears with a large number of teeth. It aims to improve the traditional calculation method and establish a more accurate model. By clarifying the differences in the geometry of gear teeth and introducing more reasonable parameters, the influence of factors such as crack levels and effective tooth thickness reduction limit lines on meshing stiffness is analyzed. The research results have important guiding significance for improving the accuracy of gear fault diagnosis and ensuring the safe operation of gear systems.

1. Introduction

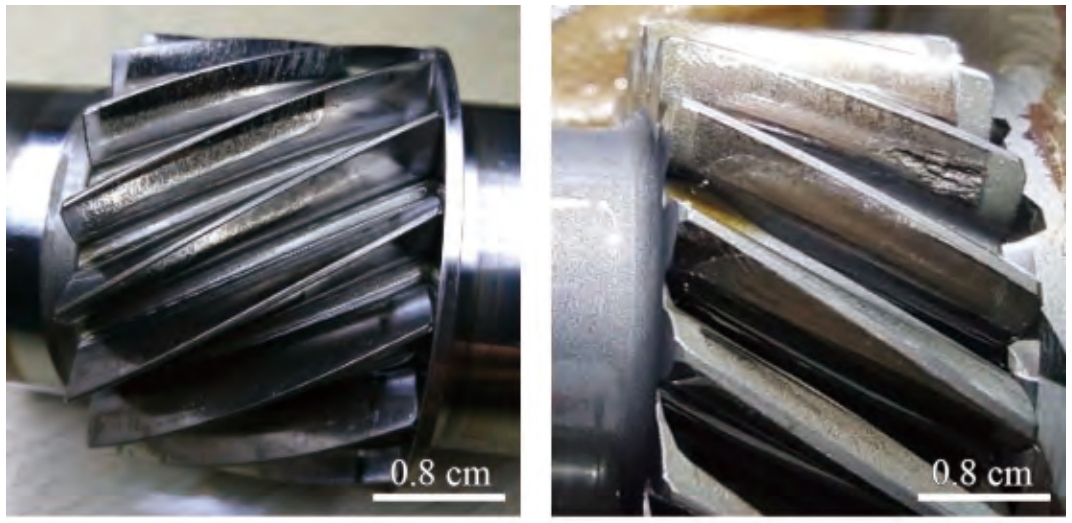

Gear systems are widely used in various industrial fields as important motion and power transmission mechanisms. However, under the development trend of modern industry towards heavy load, high speed and harsh working environments, gears are more prone to failures. Among them, tooth root cracks account for almost 40% of all gear failures. Once a failure occurs, it may cause system shutdown, economic losses and even casualties. Therefore, it is crucial to accurately detect, control and track tooth root crack failures in gear systems.

The time-varying meshing stiffness is an important parameter reflecting the meshing state of gears. It can reflect various factors affecting the gear meshing. Although the finite element method can calculate the time-varying meshing stiffness effectively, its calculation amount is large, and the meshing and post-processing processes are complex. In contrast, the energy method has higher calculation efficiency and is still the mainstream method for calculating the time-varying meshing stiffness. However, the traditional energy method also has some deficiencies, which need to be improved.

Previous studies have mainly focused on the crack propagation path and system response of gear systems at a certain crack level, while there are relatively few studies on the modeling of faulty gear teeth at different crack levels and the analysis of calculation principles. In addition, there are still some inaccuracies in the modeling of gear teeth with cracks, such as approximating the tooth root transition curve with an arc and using a straight line parallel to the gear tooth center line as the effective tooth thickness reduction limit line. Moreover, the difference between the starting point of the involute tooth profile and the intersection of the involute and the base circle has not been paid attention to. Therefore, this paper conducts in-depth research on these issues to improve the calculation accuracy of the time-varying meshing stiffness of gears with cracks.

2. Gear Geometry and Meshing Principle

2.1 Gear Tooth Profile and Transition Curve

In gear design, the tooth profile of a standard involute cylindrical spur gear is composed of an involute curve and a transition curve. The involute curve is an important part of the gear tooth profile, which determines the meshing characteristics of the gear. The transition curve connects the involute curve and the tooth root circle, and its shape has an important impact on the stress distribution and meshing performance of the gear.

For gears processed by rack-type cutters, the transition curve is the equidistant line of the long-amplitude involute, and its parameter equation is:

where is a variable parameter; is the 分度圆半径;; is the distance between the center of the cutter tip fillet and the gear tooth center line; is the distance from the center of the cutter tip fillet to the center line of the cutter tooth groove; is the modulus; is the pressure angle; and are the addendum coefficient and clearance coefficient respectively; is the radius of the cutter tip fillet.

In the gear tooth profile, there are several important points, such as the starting point of the involute tooth profile, the starting point of the transition curve tooth profile, and the intersection point of the involute tooth profile and the base circle. Their positions and the radii of the corresponding circles are calculated as follows:

where is the number of teeth. When the number of teeth is equal to a certain value, . In this paper, gears with more than 41 teeth are defined as large-number-of-teeth gears.

2.2 Traditional Potential Energy Method and Its Problems

The traditional potential energy method is a commonly used method for calculating the meshing stiffness of gears. However, it has some problems in dealing with the geometry of gear teeth. As shown in Figure 1, the traditional potential energy method model only considers the relationship between the base circle and the tooth root circle , and takes the intersection point of the involute tooth profile and the base circle as the starting point of the involute tooth profile, ignoring the fact that the points and are not the same. In addition, when the number of teeth is large, the base circle is actually located inside the tooth root circle, but the traditional potential energy method model assumes that the base circle is always outside the tooth root circle, which leads to an inaccurate description of the transition curve.

| Comparison Items | Traditional Model | Actual Situation (for large-number-of-teeth gears) |

|---|---|---|

| Position of and | Considered the same | Different |

| Position of base circle | Outside tooth root circle | May be inside tooth root circle |

| Transition curve description | Inconsistent with the actual situation | More accurate |

To solve these problems, it is necessary to correctly distinguish the starting point of the involute tooth profile and the intersection point of the involute and the base circle, and modify the traditional potential energy method according to the characteristics of the gear tooth profile of large-number-of-teeth gears.

3. Improvement of Time-Varying Meshing Stiffness Calculation Method

3.1 Modification of Gear Tooth Model

Based on the analysis of gear geometry and meshing principle, this paper modifies the traditional potential energy method gear tooth model. By distinguishing the starting point of the involute tooth profile and the intersection point of the involute and the base circle, and using the correct radius and pressure angle corresponding to the point when calculating the meshing stiffness, the accuracy of the model is improved.

When the number of teeth is not greater than 41, the traditional calculation method can be used. However, when the number of teeth is greater than 41, it is necessary to use the parameters corresponding to the point . For example, the pressure angle at the point is . In the calculation of the section inertia moment and effective cross-sectional area of the gear tooth, different expressions need to be used according to the position of the point on the tooth profile.

3.2 Calculation of Meshing Stiffness Components

The total potential energy of the meshing gear pair is composed of five components: contact stiffness , bending stiffness , shear stiffness , axial compression stiffness and tooth base stiffness . The calculation formulas of and are as follows:

where the specific meanings of each parameter can be found in the relevant literature.

The deformation energy of each component can be calculated by the following formulas:

where , , are the horizontal distances from the meshing force action point, the involute tooth profile and the tooth root transition curve to the point on the tooth root circle respectively; is the vertical distance from the meshing force action point to the point ; is the shear modulus; is the elastic modulus; is the tooth width; is the Poisson’s ratio; and are the inertia moment and effective cross-sectional area of the gear tooth section at a distance from the tooth root circle respectively.

Finally, the comprehensive time-varying meshing stiffness of the gear can be obtained by the following formula:

where the subscripts 1 and 2 represent the driving gear and the driven gear in the meshing process respectively.

4. Modeling of Cracked Gear Teeth

4.1 Different Crack Degree Models

According to the research, tooth root cracks mainly affect the bending stiffness and shear stiffness of the gear teeth. Assuming that the crack appears at the point and penetrates the entire tooth with an angle to the gear tooth center line, the crack model can be divided into four cases according to the crack propagation degree:

where ; . can be calculated by the relevant formula, ; is determined by the previous formula; other parameters have the same meaning as before.

4.2 Improvement of Effective Tooth Thickness Reduction Limit Line

The existence of tooth root cracks will lead to a reduction in the effective tooth thickness. The traditional method uses a straight line parallel to the gear tooth center line passing through the crack tip as the effective tooth thickness reduction limit line. However, when the crack exceeds 30% of the tooth thickness, the meshing stiffness calculated by this method has a large deviation from the finite element method calculation result. Therefore, some researchers have proposed using a parabola instead of a straight line as the limit line, but this method has problems such as difficult modeling and complex calculation.

In this paper, based on the analysis of the stress gradient distribution of the meshing gear teeth under load, a 斜线 connecting the crack tip point and the tooth point on the crack side is used as the effective tooth thickness reduction limit line. When the crack is above the gear tooth center line, the length of the crack is . The coordinates of the crack end point are , . The coordinates of can be obtained according to the involute characteristics. Then the expression of the effective tooth thickness reduction line can be obtained.

where is the ordinate of the point at a horizontal distance from the equivalent cantilever beam, which can be calculated by the above formula.

When the crack extends below the gear tooth center line, the length of the crack is , and the coordinates of the crack end point are , . Similarly, the expression of can be obtained, and the expressions of , , and are the same as those in the previous case.

5. Calculation Results and Analysis

5.1 Influence of Gear Tooth Model Correction

In order to study the influence of gear tooth model correction on the calculation of meshing stiffness, four crack levels are selected, namely , , and , corresponding to crack depths of , , and respectively. Two solution methods are defined: Method 1 does not correct the gear tooth model, and Method 2 corrects the gear tooth model. The effective tooth thickness reduction limit line of both methods is a straight line.

The calculation results show that the meshing stiffness reduction percentages of Method 1 and Method 2 are relatively close and have the same change trend as the finite element method. With the increase of the crack level from to , the reduction degree of the time-varying meshing stiffness in the single-tooth and double-tooth meshing areas of Method 1 and Method 2 increases continuously. When the crack extends to a higher level, the time-varying meshing stiffness is significantly reduced compared with that of the healthy gear teeth, about . In the double-tooth meshing area, the stiffness reduction amplitude in the latter meshing cycle is greater than that in the previous meshing cycle. This is because when the cracked gear tooth contact point moves from the tooth root to the tooth tip, the effective contact length increases, resulting in an increase in the proportion of the bending stiffness and shear stiffness of the cracked gear tooth in the comprehensive meshing stiffness, making the crack effect more prominent.

In addition, the meshing stiffness calculation result of Method 1 is smaller. This is because Method 1 confuses the difference between the starting point of the involute tooth profile and the intersection point of the involute and the base circle. When the number of teeth is greater than 41, the base circle radius is already inside the tooth root circle. Method 1 takes the point as the upper limit of integration, and calculates more deformation energy of the section. Since the deformation energy is inversely proportional to the meshing stiffness, the meshing stiffness calculation result is smaller.

5.2 Influence of Effective Tooth Thickness Reduction Limit Line

To analyze the impact of the effective tooth thickness reduction limit line on the meshing stiffness calculation, three methods are defined. Method 2 uses a straight line as the limit line, Method 3 uses a parabola, and Method 4 (the method in this paper) uses a diagonal line. The time-varying meshing stiffness is calculated for crack levels of 20%, 40%, and 60%.

When the crack level is low (CL = 20%, CL = 40%), the time-varying meshing stiffness curves of the three methods are relatively close to the finite element method. At the moments A’ and B’, the relative errors of the three methods compared to the finite element method are all within 2%. This indicates that when the crack size is small, the specific form of the effective tooth thickness reduction limit line has little influence on the meshing stiffness calculation. Although using a diagonal line or a parabola can reduce the calculation error to a certain extent, it also increases the complexity of modeling and calculation. Therefore, it is reasonable to assume that the effective tooth thickness reduction limit line is a straight line when calculating the time-varying meshing stiffness of small-sized cracked gears.

When the crack level is high (CL = 60%), at the moment A’, the relative error of Method 2 is 4.68%, while the relative errors of Method 3 and Method 4 are both around 3%, and the meshing stiffness values are relatively close. At the moment B’, the relative error of Method 2 compared to the finite element method reaches 12.14%, much higher than 0.07% of Method 3 and 2.09% of Method 4. This shows that when the crack size is large, using a straight line as the effective tooth thickness reduction limit line does not conform to the actual situation, and using a diagonal line or a parabola is more reasonable. Considering the difficulty of modeling and calculation efficiency, although the error of Method 4 is slightly larger than that of Method 3 at the moment B’, a relative error of about 2% can still meet the calculation accuracy requirements. The parabolic equation has various forms and many unknown parameters, while the diagonal line only needs two points’ coordinates, making the modeling simple and the calculation convenient, and having stronger practicability.

6. Conclusion

- For spur gears with more than 41 teeth, by combining the gear cutting geometry and tooth profile envelope principle, this paper clarifies the difference between the starting point of the involute tooth profile and the intersection of the involute and the base circle, introduces the tooth root transition parameter curve and a more realistic effective tooth thickness reduction limit line, and improves the traditional potential energy method gear tooth time-varying meshing stiffness calculation formula. A more rigorous and comprehensive model for calculating the time-varying meshing stiffness of faulty gear teeth at different crack levels is established.

- Based on the improved cracked gear tooth model, the time-varying meshing stiffness at different crack levels is calculated. The results show that when calculating the time-varying meshing stiffness of large-number-of-teeth gears, not correcting the gear tooth model will lead to a smaller calculation result. Tooth root cracks will cause a decrease in meshing stiffness, and the decrease amplitude is greater in the second meshing cycle. As the crack degree increases, the decrease amplitude of meshing stiffness also increases.

- When the crack size is small, the specific form of the effective tooth thickness reduction limit line has little influence on the calculation of the time-varying meshing stiffness. At this time, it is recommended to use a straight line as the effective tooth thickness reduction limit line. When the crack size is large, the straight-line reduction limit line does not conform to the actual situation of the crack. Compared with the parabola, the diagonal line can meet the calculation accuracy requirements to a certain extent, and has the advantages of simple modeling and convenient calculation, and has stronger practicability. Therefore, it is recommended to use a diagonal line as the effective tooth thickness reduction limit line at this time.