Gear hobbing machine is widely used in automobile, machine tool, engineering machinery and other machinery manufacturing industries. In gear hobbing, there are many innovations in tool materials, process technology and process integration. Many scholars at home and abroad have done a lot of research work on gear hobbing.

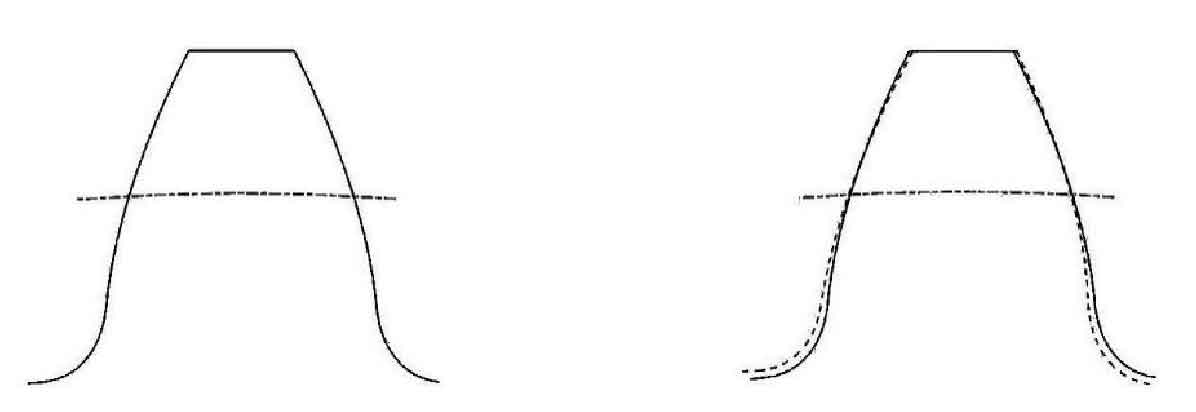

Liu runai of Chongqing University and others, through the research on the gear hobbing processing technology in China, discussed that the development trend of gear hobbing processing is developing in the direction of full digital control, high speed, high precision, zero transmission, integration, environmental protection, intelligence and networking. Zhao Jiao of Shanghai Jiaotong University and others decomposed the kinematic meshing relationship between the tool shaft and the workpiece shaft, and established the synchronous control model of gear hobbing. The discrete points are used to represent the graphic simulation method of gear continuous machining, and the cutting simulation of gear hobbing process is realized. Wu Ping’an of Taiyuan University of technology and others established hob coordinate system and gear coordinate system in two-dimensional plane rectangular coordinate system. Through the method of coordinate transformation, the tooth profile equation of gear is derived, and the tooth profile error is analyzed considering the intersection angle error of hob installation axis, as shown in Figure 1. When only the intersection angle error of hob installation shaft is considered, the left and right tooth profiles of gear teeth are asymmetric.

Zhang Jin of Nanjing University of technology and others simulated the gear hobbing process by envelope method, and obtained the gear profile curve. Xu Rui of Chongqing University and others used AutoCAD and VB programming to realize the gear hobbing machining simulation of hob tooth profile obtained by envelope method. Wu Kangmei of Jilin University of technology and others established the mathematical model of gear hobbing based on the motion relationship in gear hobbing, and obtained the gear profile through numerical calculation. Wei Yan of Dalian Jiaotong University and others use the spatial meshing theory to describe the gear root transition curve in the form of quadratic Lagrange interpolation curve.

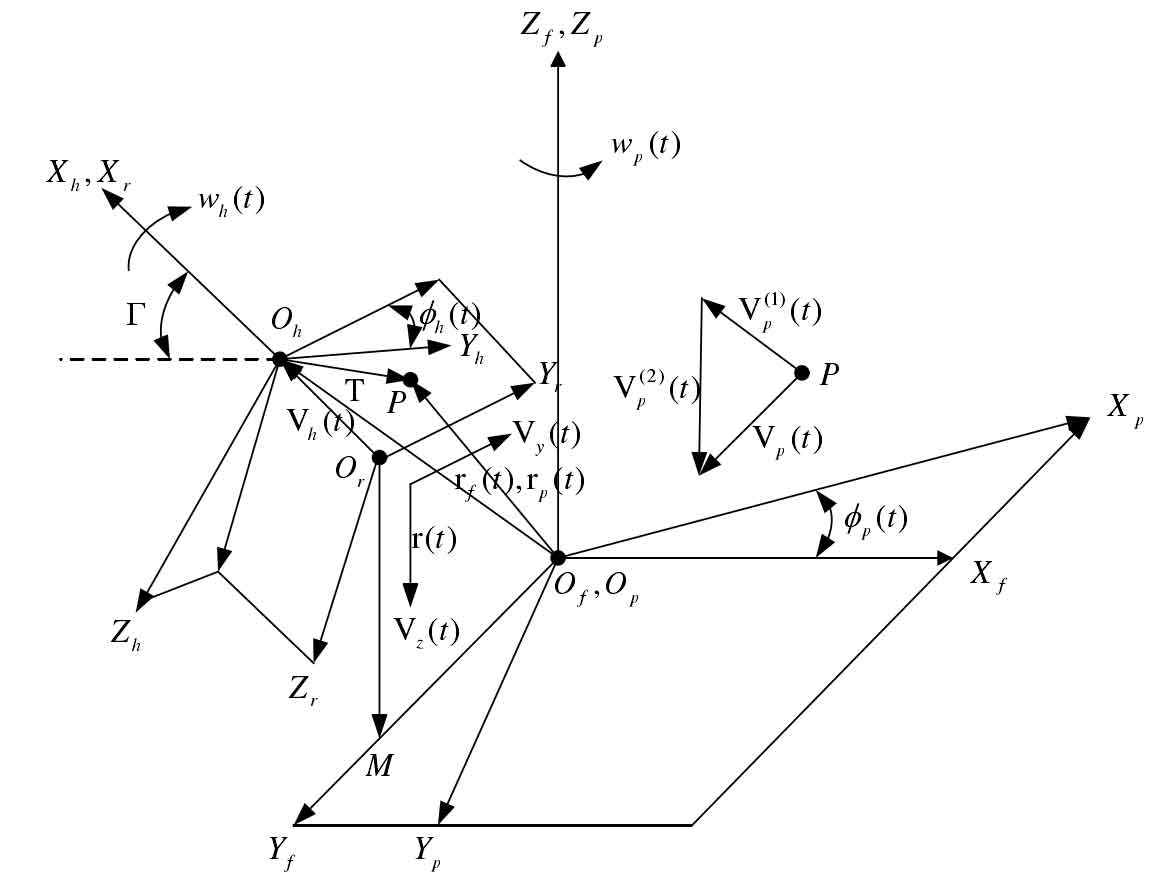

Zhang rongchuang of Northeastern University proposed a three-dimensional simulation method of gear hobbing based on solid modeling. In this method, the motion vector model of gear hobbing is established by analyzing the motion relationship and position relationship between hob and workpiece, as shown in Figure 2. Based on UG platform, the rake face model of hob teeth and the geometric model of spatial motion trajectory curve of hob teeth are constructed. By Boolean subtraction between the swept body of cutter teeth and the instantaneous cogging entity, the undeformed geometric cutting entity and the geometric model of tooth profile are obtained. The error between the simulated tooth profile and the theoretical tooth profile obtained by the model is 0.6 μ m 0.8 μ M.

Lao Qicheng of Xi’an University of technology and others established the three-dimensional model of hob by using Pro / engineer software, and dynamically simulated the gear hobbing process by using DEFORM-3D software. The variation law of cutting force with cutting time, the law of maximum equivalent stress in gear hobbing process, the distribution of cutting temperature and the wear of hobs are obtained. Wang Zhonghou of Shanghai University of technology and others studied the computer virtual machining of involute helical gear with hob by using the macro program function in CATIA, obtained the fine curved surface to form the gear tooth surface, and realized the simulation machining of the whole gear model. Zhao Jijun of Harbin Institute of technology and others established a standard spatial thickened gear model by analyzing the kinematic relationship of hobs. According to the processing parameters required by gear thickening, the gear hobbing processing is simulated by VERICUT machine tool simulation software. Zhang Rui of Taiyuan University of technology put forward the tooth contact analysis and computer simulation method of helical gear, and studied the sensitivity of hob installation error to gear pair meshing. Han Jiang of Hefei University of technology and others obtained the topological structure of NC gear hobbing machine by analyzing the kinematic relationship and geometric error of NC gear hobbing machine tool.