Tianxijie of Shandong University comprehensively analyzed the research status of precision forging technology and tooth profile modification technology of spur bevel gears at home and abroad, proposed and realized the isometric milling modification process of precision forged spur bevel gears, and realized the modification of precision forging die cavity by using the method of chemical cutting, so as to realize the tooth profile modification of precision forged spur bevel gears, The uniformity of chemical iron cutting of red copper can be ensured. At the same time, according to the structural characteristics of the modified gear, the mathematical model is established to check the demoulding of any modified part on the internal surface of the precision forged spur bevel gear based on whether the demoulding can be carried out smoothly after the tooth shape modification. Based on the SolidWorks system, the calculation program for the demoulding of the precision forged spur bevel gear is compiled.

Zhang Yane of Shandong University analyzed the research status of precision forging process for spur bevel gears. In view of the problems existing in the “one fire two forging” process for forming spur bevel gears with large modulus or large modulus, such as insufficient filling of tooth tip, excessive forming load, short service life of tooth die, a new nonlinear expansion model for tooth profile design of hot forging was established, The nonlinear expansion curve equation of the tooth profile of hot forging is put forward. Because the equation is an accurate mathematical relation, the accuracy of the tooth profile design of precision forging of spur bevel gears is further improved.

Qiudehua et al. Developed the forging process route based on the hot-cold composite forming process of typical differential planetary gears. They used pro/e software to design the standard pre forging tooth profile scheme. After importing the software from-3d, they conducted numerical simulation on the pre forging deformation process of different tooth profile schemes. After the numerical simulation and comparative analysis, they conducted physical test verification, The advantages and disadvantages of standard and non-standard pre forged tooth profile design are summarized.

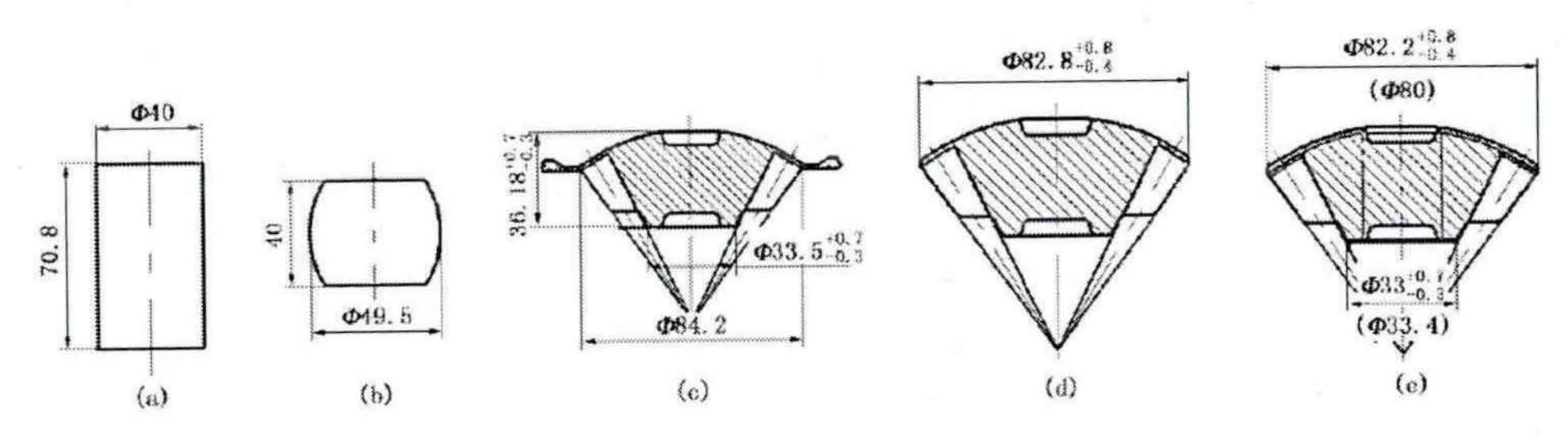

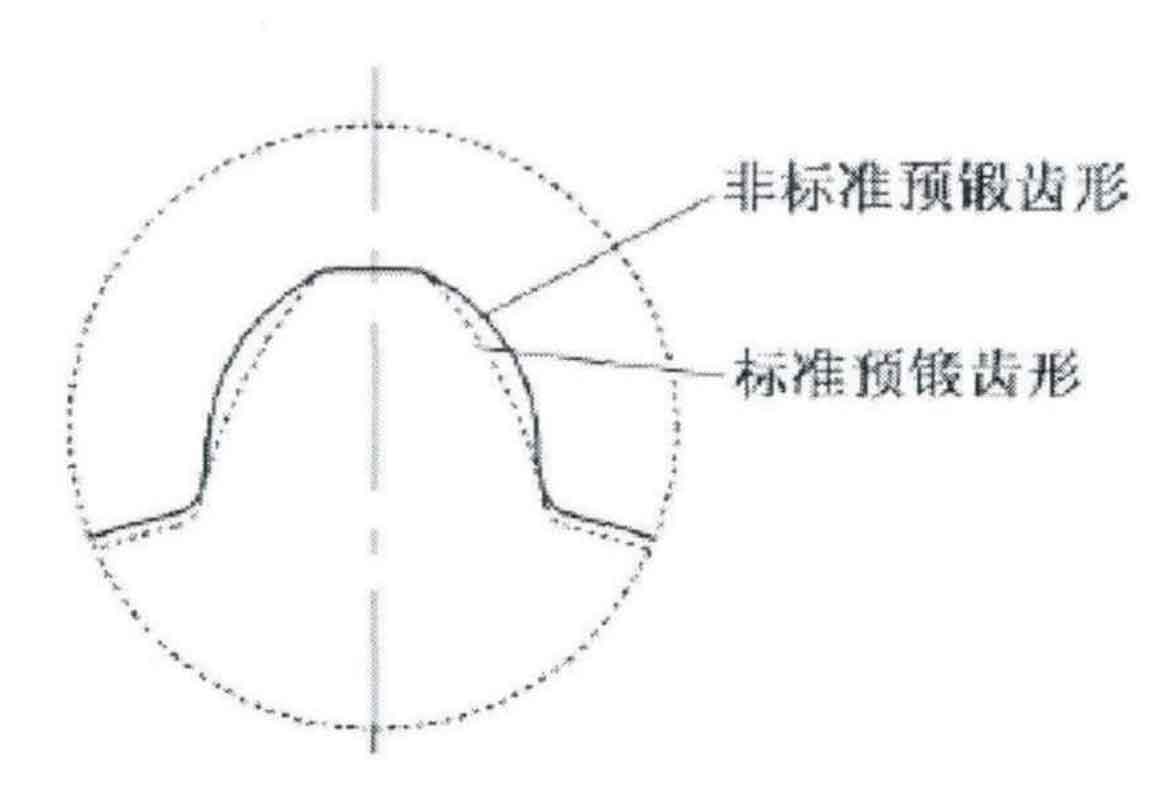

The pre forged tooth profile of the standard tooth profile method is a uniform displacement of the tooth surface outward on the basis of the cold forging drawing according to the cold finishing amount; As the volume remains unchanged, the tooth root circle shrinks evenly inward. The non-standard pre forged tooth profile is shown in Figure 2.

The 3D forging modeling based on the non-standard pre forged tooth profile design is imported into the Defrom-3D software for numerical simulation. The simulation results are shown in Figure 3. The equivalent effect nephogram of the tooth surface during the leveling process with non-standard pre forged tooth profile and standard pre forged tooth profile (scheme 4) is extracted, as shown in Figure 4. It can be seen from the figure that the effect of cold finishing tooth surface with non-standard pre forged tooth profile is greater than that with standard pre forged tooth profile, the quality of tooth surface is improved after cold finishing, and the optimization scheme has better cold finishing effect than that with standard pre forged tooth profile.

According to the scheme 4 standard pre forged tooth profile and the optimized pre forged tooth profile, the die design, machining and physical test are carried out respectively. The test conditions are the same. Based on the comprehensive numerical simulation analysis results, the following conclusions can be drawn: if the standard pre forged tooth profile is adopted, the finishing amount is small, the tooth surface will have a low forming precision, the finishing amount is large, defects will occur at the tooth root, and there are metal folds; If the non-standard pre forged tooth shape is adopted, the hot forging shall reach the part specification after cold finishing. Therefore, it is a reasonable scheme to determine the pre forged tooth profile as non-standard tooth profile.