i02 is the roll ratio of the machine tool and the process pitch cone of the spiral bevel gear. As shown in the figure, the node of the process pitch cone coincides with the designed node, and the pitch cone bus of the large and small wheels passing through the meshing point also coincides with that of the process pitch cone. Moreover, the helix angle of the process pitch cone is equal, which is equal to the nominal helix angle of the spiral bevel gear β, It can be obtained from the figure:

Then the root cone pressure angle of the large wheel can be obtained from the geometric relationship of the spiral bevel gear wheel embryo design:

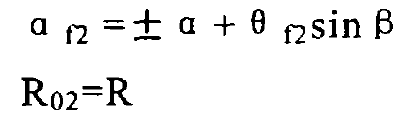

By substituting the formula into the formula, the machine tool adjustment parameters of spiral bevel gear wheel can be obtained:

When machining a small wheel with the denaturation method, the blade tip plane is tangent to the root cone of the small wheel, so the pitch cone angle of the small wheel cutting tooth is equal to the root cone angle, which does not need to be corrected. When we use the tooth shape angle α 01≠ α When the F1 cutter head is used to process the small wheel, the small wheel must be rotated by an angle around the axis. The root cone pressure angle of the small wheel can be obtained from the geometric relationship of the spiral bevel gear wheel embryo design λ, The root cone pressure angle of the small wheel can be obtained from the geometric relationship designed by the wheel embryo of spiral bevel gear:

β A1 – helix angle of face cone of small wheel

Theoretical normal vector and curvature of calculation point of pinion tooth surface:

Since the small wheel is processed by the denaturation method, the actual normal vector of the calculation point of the small wheel tooth surface is:

i. The relationship between J, K and I1, J1, K1 is:

Therefore, Na1 = NF1, from which the spiral angle of small wheel cutting pitch cone can be obtained:

The following equations are obtained from the formula:

From this set of equations, the small wheel angle can be obtained λ:

When the wheel turns λ After the angle, the included angle between the tooth length direction EA1 of the process pitch cone of the small wheel and the tooth length direction EF1 of the cutting pitch cone Δ By sin Δ Get: