Compared with mechanical press, friction press has no fixed bottom dead center, convenient installation and debugging of die and less sensitivity to the change of forging thickness; The punch reaches the bottom dead center and the return speed is very fast, the output energy is large, which is conducive to forming, the die pressing time is short, and the working conditions of the die are good. Compared with the forging hammer, the hammer head of the friction press has high precision, slow speed, low vibration and low noise, the die is not easy to dislocation, and the forging precision is high; The strain rate is low, the deformation resistance is small, and the condition of metal sequential filling cavity is good. Therefore, friction screw press is the preferred forging equipment for precision forging bevel gear.

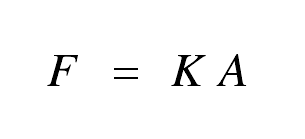

When selecting the tonnage of friction press, the process characteristics and actual production conditions of the equipment should be considered. According to the actual production experience, the forming force of precision forged bevel gear can be determined by the following formula:

Where, a – Horizontal projected area of forging, unit: cm2; K-coefficient, at 1200 ℃, it is 80KN / cm2 for forgings with clear contour, 50kN / cm2 for forgings with certain rounded corners, and 120 ~ 150 kn / cm2 for forgings with high reinforcement and thin wall.

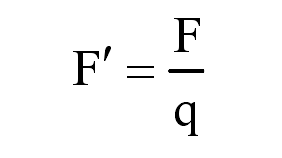

When selecting the tonnage of friction press required for precision forging bevel gear, first calculate the precision forging force of bevel gear, and then determine the equipment tonnage according to the deformation characteristics. The formula is as follows:

Where, f ‘- nominal pressure; Q – deformation coefficient, 1.6 for fine pressed parts with small deformation degree, 1.3 for forgings with slightly large deformation degree, and 0.9 ~ 1.1 for forgings with large deformation degree.

| Model | J53-1000 |

| Nominal pressure (ton) | 1000 |

| Maximum kinetic energy of flywheel (kg / M) | 16000 |

| Slider stroke (mm) | 700 |

| Number of trips (times / min) | 10 |

| Minimum closing height (mm) | 700 |

| Thickness of workbench base plate (mm) | 200 |

| Bottom dimension of slider (front and rear) × Left and right) (mm) | 820×820 |

| Table size (front and rear) × Left and right) (mm) | 1200×1000 |

| Main motor (motor) | 75 |

| Total capacity (motor) | 75 |

| Number (motor) | 1 |

| Overall dimension (length) × wide × Height (mm) | 6000×5670×7225 |

According to the formula, the precision forging force of bevel gear is f = 12491.09kn, and the equipment tonnage is f ‘= 7806.9kn. Therefore, 10000kN friction press can be selected, and the model is j53-1000c. As shown in table j53-1000 double disc friction press.