In the motion simulation module of UG software, the motion simulation model of half shaft gear and planetary gear meshing is established by using the transmission ratio and motion relationship to simulate the cold contact area at multiple times. Then, the size and position of the contact area are judged by the simulation of the contact area, and then the modification amount is fed back and continuously adjusted. In this way, the product quality is controlled in the design stage, so as to avoid unqualified workpieces in the processing stage.

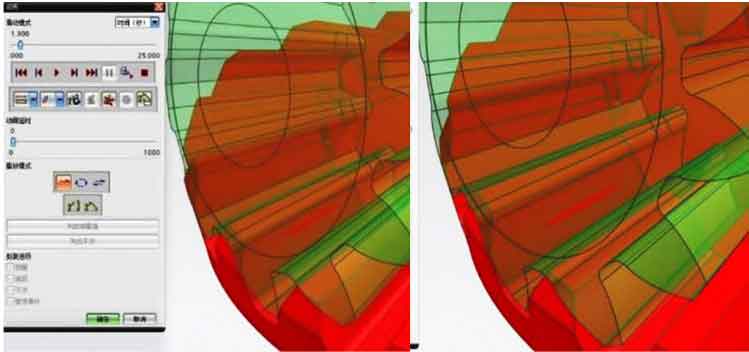

The established three-dimensional digital models of the half shaft gear and planetary gear are imported into the motion module of UG software, and the nodes of the two gears are overlapped. The two gears are assembled according to the actual motion. The tooth surface interference is set to 0.005 mm, the motion time is set to 30 s, and the rotation speed is set to 50 R / min. The simulation of the contact area is as shown in the figure.

It can be seen from the figure that the contact area is in good condition at the two arbitrary motion moments. Under no-load condition, the contact area is close to the small end and occupies about 50% of the length of the tooth length direction, which preliminarily verifies the correctness of the digital simulation design.