At present, the dynamic excitation of gear transmission system is divided into external and internal excitation. Among them, the external excitation refers to the excitation applied to the transmission system by the outside, most of which is caused by the main torque of the prime mover. Conversely, the excitation generated inside the transmission system is called internal excitation. Most studies aim to improve the internal excitation of the gear train by changing the structural parameters of the gear train or tooth modification, so as to achieve the purpose of vibration reduction and noise reduction, while ignoring the improvement of external excitation.

The input end of the planetary gear train can be the sun gear, planet carrier and inner gear ring. Without changing the structural parameters and excitation characteristics of the gear train, the dynamic characteristics of the gear train can be studied and analyzed by changing the excitation position of the planetary gear train, so as to achieve the purpose of vibration reduction and noise reduction.

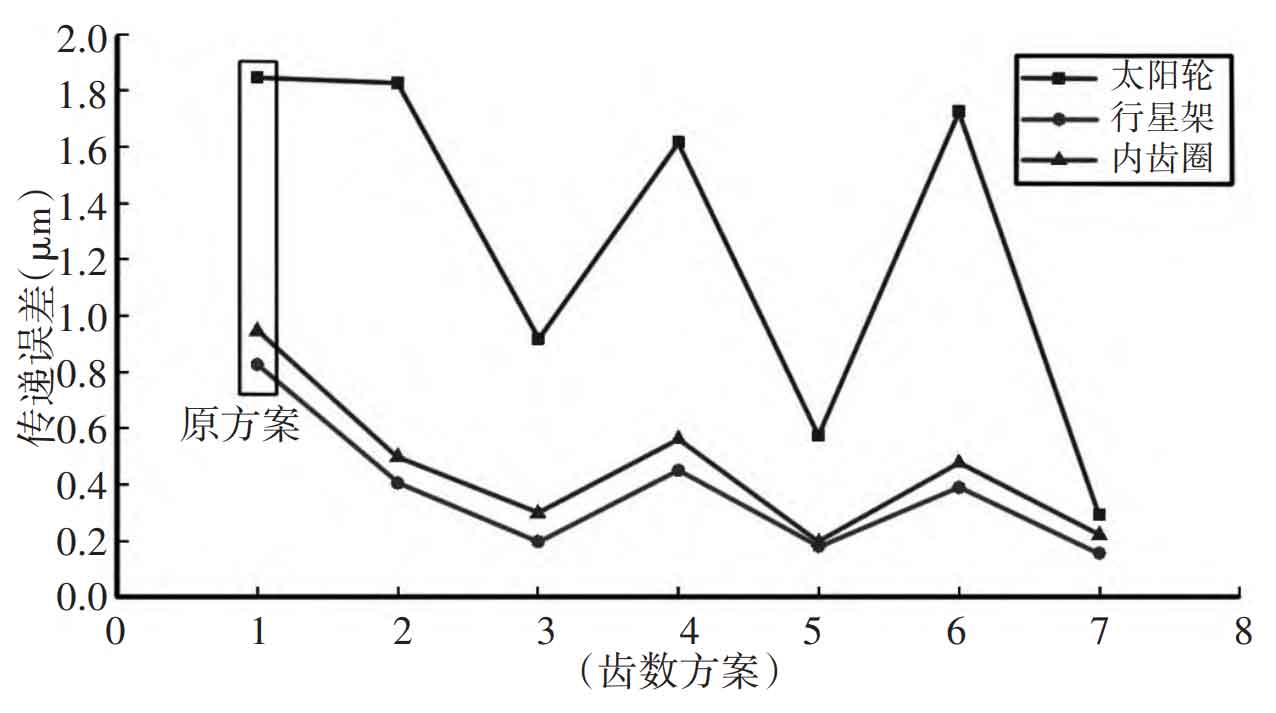

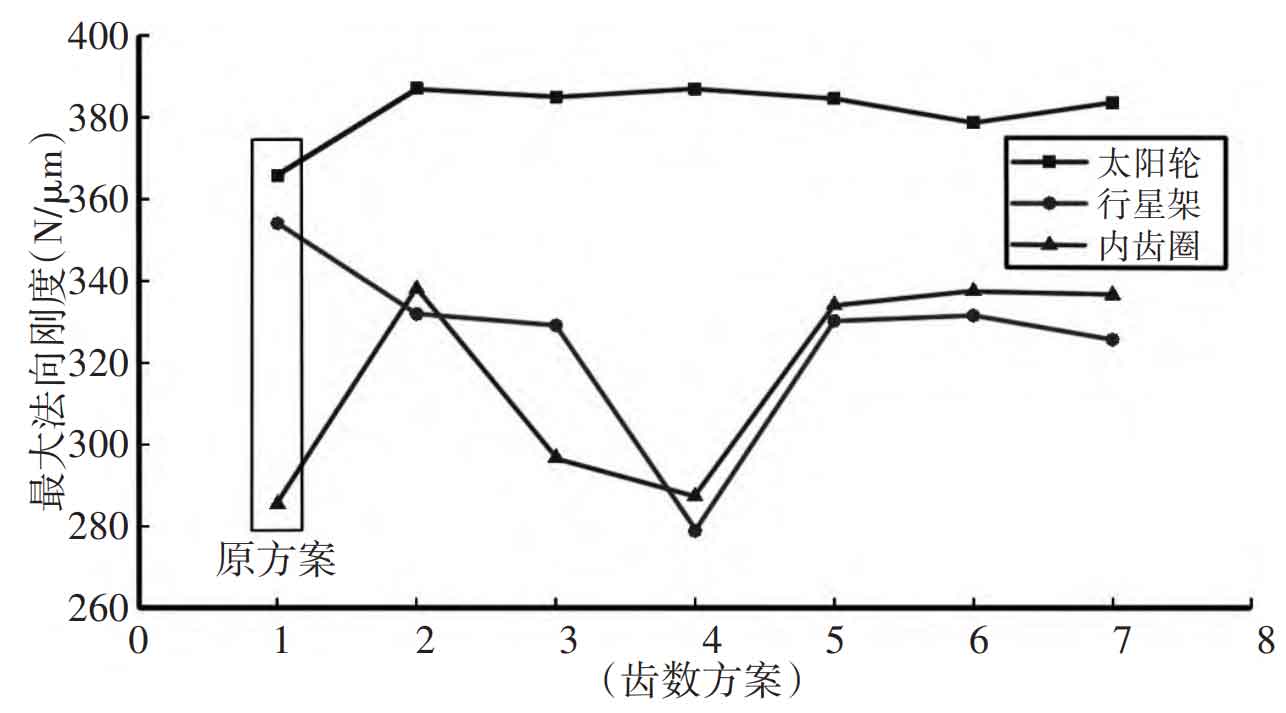

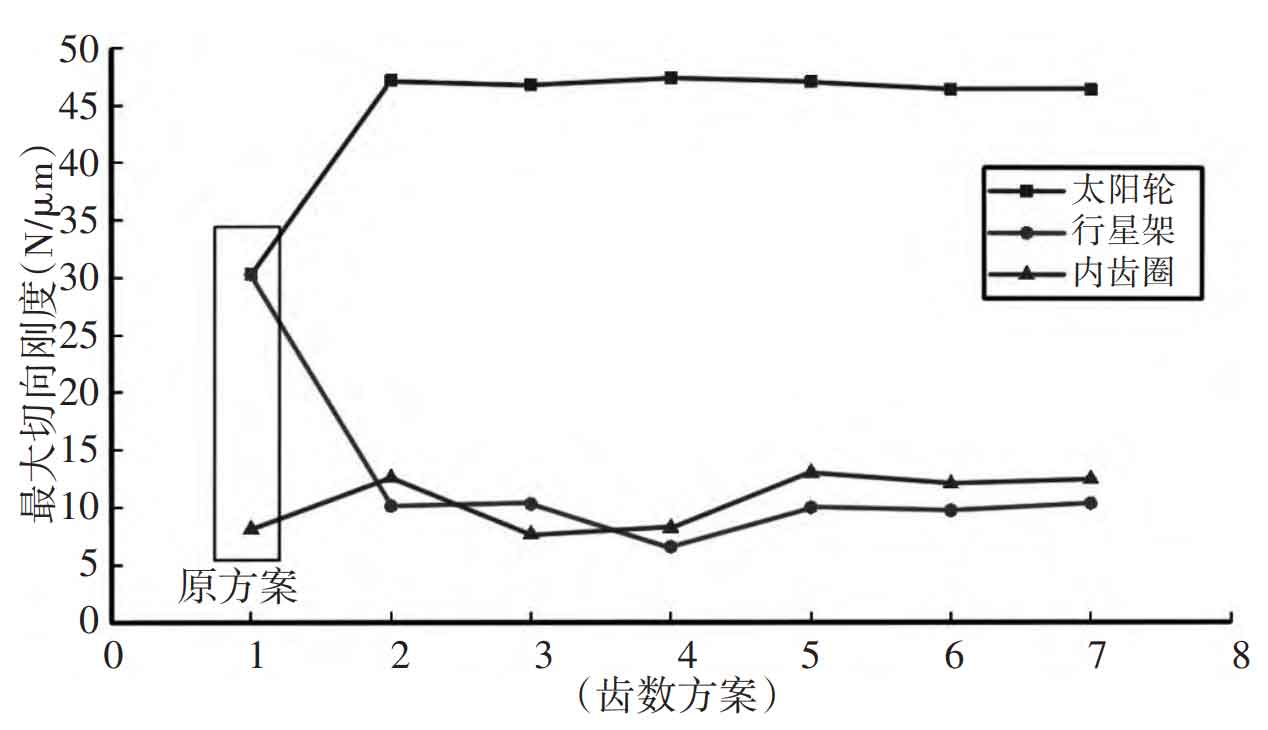

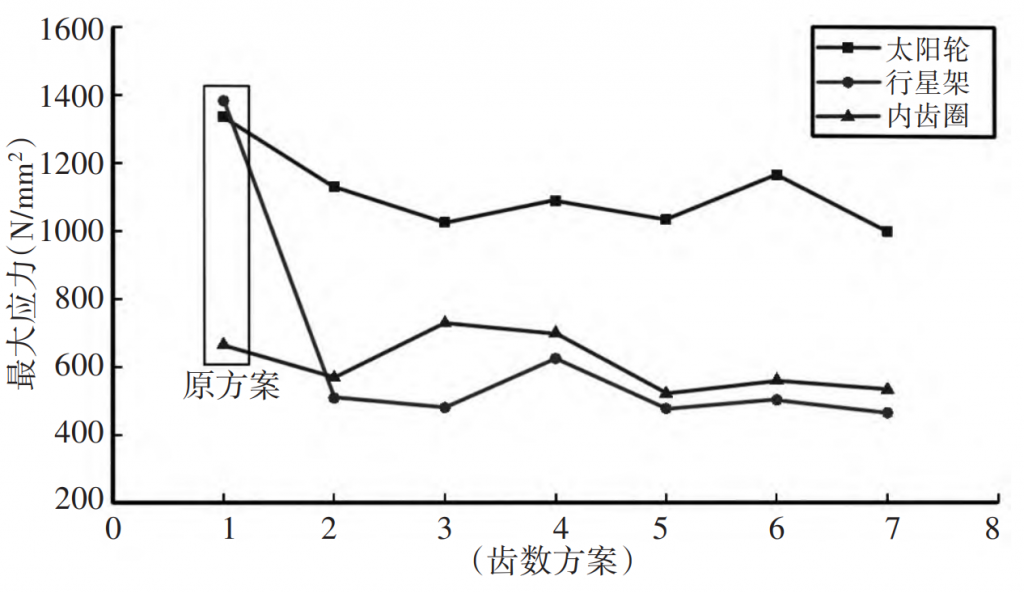

The original tooth number scheme and the six groups of tooth number schemes obtained above are simulated and analyzed, and the data of transmission error, maximum normal stiffness, maximum tangential stiffness and maximum stress obtained by different tooth number schemes are compared graphically, as shown in Fig. 1 ~ Fig. 4.

| Serial number | Sun wheel | Number of teeth Z planetary gear | Inner ring gear | Number of teeth coprime type | X |

| 1 | 27 | 39 | 108 | — | yes |

| 2 | 27 | 40 | 108 | Sun gear and planet gear | yes |

| 3 | 28 | 39 | 108 | Sun gear and planet gear | no |

| 4 | 27 | 39 | 107 | Planetary gear and internal gear ring | yes |

| 5 | 28 | 38 | 107 | Planetary gear and internal gear ring | no |

| 6 | 27 | 40 | 111 | Sun gear, planet gear and planet | yes |

| 7 | 29 | 40 | 109 | Wheel and internal gear ring | no |

In Figure 1-4, abscissa 1-7 respectively represent different tooth number schemes, 1 is the original tooth number scheme, and 2-7 are the first to sixth tooth number schemes in the table. Through the analysis of the above chart, it can be concluded that when the planetary gear train takes the planet carrier as the input end, its working state is better than that when the sun gear or inner ring gear is used as the input end. Taking the seventh group of teeth scheme as an example, when the planet carrier is used as the input end, compared with the sun gear as the input end, the transmission error is reduced from 0.292 µ m to 0.157 µ m, which is reduced by 46.2%; When the sun gear is used as the input end, the normal stiffness is 383.4678n/µ m and the tangential stiffness is 46.3794n/µ M. when the planet carrier is used as the input end, the normal stiffness is reduced to 325.6931n/µ m and the tangential stiffness is reduced to 10.4201n/µ m, reduced by 15% and 77.5% respectively; When the sun gear is the input end, the maximum load on the tooth surface is 998.281n/mm2, and when the planet carrier is the input end, the maximum load on the tooth surface is 464.438n/mm2, which is reduced by 53.5%. In addition, through the contact analysis of TCA tooth surface, it can be concluded that when the planetary gear train takes the planet carrier as the input end, the gear bending strength and contact strength are better than those of the sun gear and inner ring gear as the input end.

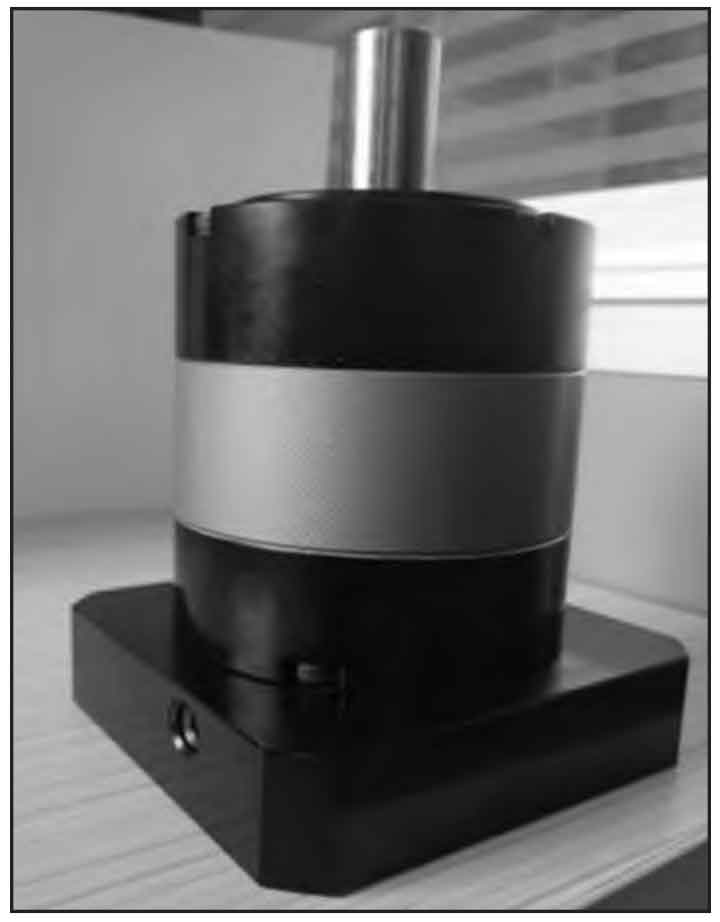

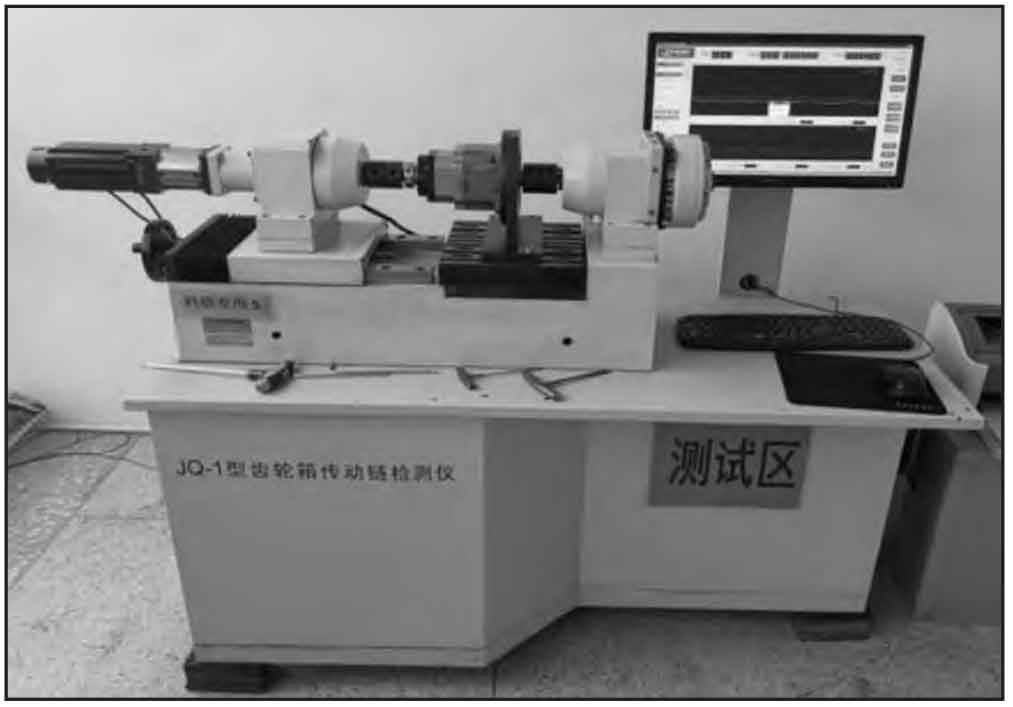

Finally, based on the obtained theoretical simulation results, taking the seventh group of optimal parameters as the scheme, a reducer entity is processed, as shown in Figure 5. The test is carried out in the gearbox tester, as shown in Figure 6. The results show that the detection data are very close to the theoretical data. The experimental verification provides a feasible basis for the vibration and noise reduction of this type of reducer.