1. Introduction

1.1 Significance of Gear Contact Fatigue Life Research

Gears are crucial components in various mechanical transmission systems, such as helicopter main reducers, advanced high – bypass – ratio turbofan engines, and gas turbine main reducers. These systems often operate in complex and harsh environments with high – speed and heavy – load conditions. Ensuring the reliable operation of gears is of great significance for the overall performance and safety of the mechanical equipment. Contact fatigue is one of the main failure modes of gears, which can lead to tooth surface pitting, wear, and even tooth breakage, seriously affecting the service life and reliability of gears. Therefore, studying the contact fatigue life of gears is essential for optimizing gear design, improving gear quality, and reducing maintenance costs.

1.2 Research Methods and Their Limitations

Currently, the research methods for gear contact fatigue life mainly include numerical simulation calculation based on fatigue damage theory, direct testing based on traditional contact fatigue testing machines, and life prediction based on finite element simulation modeling.

- Traditional Contact Fatigue Testing: This method can obtain reliable experimental data, which can be used to fit empirical models. However, it has several drawbacks. The test cycle is extremely long, and it is difficult to obtain aviation – grade gear materials. Conducting relevant tests on gear transmission systems used in aero – engines and gas turbines requires a large amount of resources, making it costly and time – consuming.

- Numerical Simulation Calculation: It has the advantages of high calculation efficiency and relatively high accuracy. Nevertheless, most numerical simulations are based on two – dimensional plane modeling, which makes it difficult to consider the contact fatigue changes in the tooth width direction and three – dimensional plane. As a result, it lacks intuitive explanations and descriptions for predicting gear fatigue damage areas.

- Finite Element Simulation Modeling: In recent years, with the development of computer technology and finite element software, finite element simulation modeling has become an important means of gear contact fatigue life research. However, in current simulation studies, there are still some problems, such as inaccurate compilation of cyclic load spectra, lack of consideration of gear working environment variables and tooth surface boundary conditions, and failure to combine with the results of numerical simulations.

1.3 Objectives of This Study

This paper aims to address the existing problems in gear contact fatigue life research. By using Ansys Workbench and nCode for finite – element analysis, calibrating finite – element simulation results through Hertz contact pressure, considering the elastohydrodynamic lubrication friction coefficient with tooth surface roughness, and compiling time – step load spectra based on full – size gears, a spur gear contact fatigue model is established. The study focuses on exploring the effects of multiple working conditions and surface integrity on contact fatigue, providing a reference for subsequent contact fatigue and pitting morphology test plans and material selection.

2. Spur Gear Meshing Process Analysis

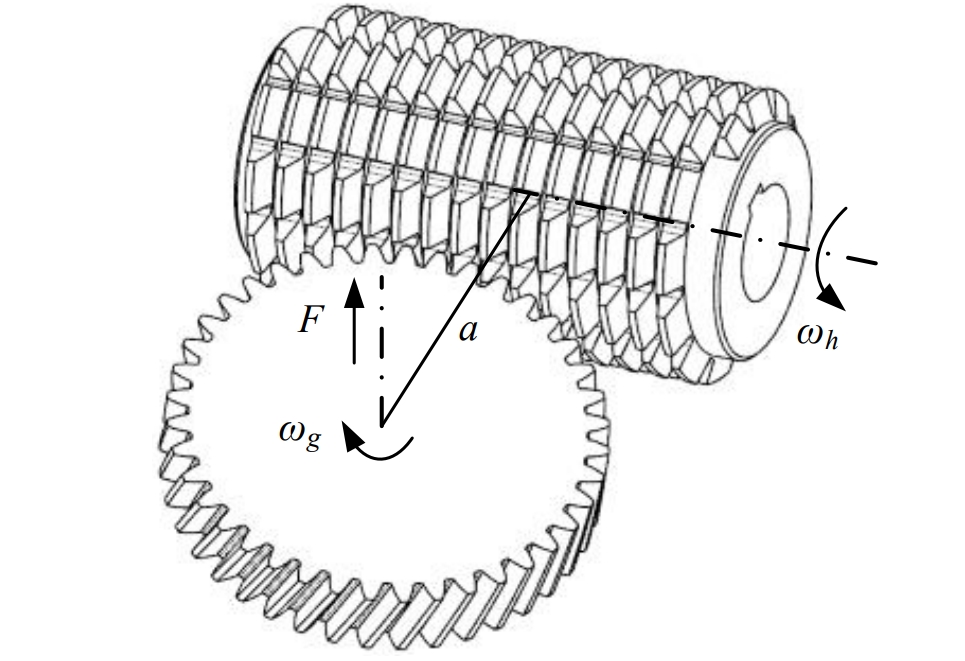

2.1 Basic Parameters of Spur Gears

The basic parameters of the spur gears used in a certain contact fatigue testing machine are shown in Table 1. These parameters are the basis for gear design, analysis, and simulation. Different gear parameters will affect the meshing performance, contact stress distribution, and contact fatigue life of gears.

| Gear Parameters | Driven Gear | Driving Gear |

|---|---|---|

| Number of Teeth | 24 | 16 |

| Module/mm | 4.5 | 4.5 |

| Pitch Circle Diameter/mm | 108 | 72 |

| Tooth Width/mm | 20 | 20 |

| Transmission Efficiency | 0.97 | 0.97 |

| Table 1: Gear Basic Parameters |

2.2 Tooth Surface Contact Strength

In the verification of tooth surface contact fatigue strength, Hertz contact stress is mainly used as the main stress for calculation. As shown in Figure 1, experiments have shown that the area near the pitch line at the tooth root is most prone to pitting. Therefore, the contact stress at node P is taken as the basis for calculating the tooth surface contact stress. After simplification, the calculation formula for tooth surface contact strength is as follows.

2.3 Tooth Surface Friction Coefficient Considering Tooth Surface Roughness

According to the time – varying friction coefficient formula in the elastohydrodynamic lubrication state obtained from a large number of experiments in the literature, when the tooth surface roughness is 0.2μm, 0.4μm, and 0.6μm, the calculated tooth surface friction coefficients are shown in Figure 2. By calculating the root – mean – square value of the friction coefficient, the corresponding friction coefficients are 0.014, 0.021, and 0.042 respectively. The tooth surface friction coefficient has an impact on the contact fatigue life of gears. A smaller friction coefficient may indicate a larger oil film thickness between the tooth surfaces, but an excessive oil film thickness may also lead to an increase in the viscosity of the lubricating oil between the tooth surfaces and an increase in the contact pressure.

3. Establishment of Spur Gear Contact Fatigue Finite – Element Simulation Model

3.1 Static Analysis Model of Spur Gears

- Gear Modeling and Mesh Generation: According to the parameters in Table 1, the gear is modeled, and the tooth contact model is meshed in Hypermesh. Hexahedral elements are used for meshing. The driving gear single – tooth model has 239,646 nodes and 215,700 elements, and the driving gear base – circle single – tooth model has 4,900 nodes and 4,000 elements. Rotational replication is carried out according to the tooth number angle relationship to ensure the accuracy of contact stress calculation, as shown in Figure 3.

- Setting of Boundary Conditions and Loads: According to the gear meshing input – output relationship, when the load torque is 30,000 Nmm, the input torque of the driving gear is 20,619 Nmm. The joint – revolute is used to set the single – degree – of – freedom revolute pair of the driving gear, and the joint – fixed is used to set the driven gear as a fixed revolute pair.

- Verification of Simulation Results: After solving through Workbench, the contact stress results corresponding to the set load torque are obtained, as shown in Figure 4. By comparing the finite – element solution with the theoretical solution, as shown in Table 2, it can be seen that the error between the simulation calculation and the theoretical solution is within 5% and is basically higher than the theoretical solution. Therefore, the simulation results are considered relatively reliable and can be used for conservative life prediction.

3.2 Transient Dynamics Analysis Model of Spur Gears

- Modeling and Mesh Generation: According to Table 1, a full – size model is established to obtain an accurate stress – time sub – step history. In Hypermesh, considering the calculation resource utilization rate and calculation efficiency, the overall number of meshes is controlled. The overall gear model has 103,840 nodes and 86,080 elements, as shown in Figure 5.

- Setting of Boundary Conditions and Loads: The joint – revolute is used to set the rotational speed of the driving gear, the joint – moment is used to set the load torque of the driven gear, and in the contact setting, the root – mean – square value of the tooth surface friction coefficient calculated in 1.3 is used.

3.3 Material S – N Curve

The material of a certain type of aviation gear is Cr alloy forged steel, with a tensile strength of 1010 MPa. Since this material does not exist in the nCode material library, the S – N curve needs to be conservatively estimated using the method of a modified S – N curve, as shown in Figure 6. The S – N curve is an important basis for calculating the fatigue life of materials, which reflects the relationship between the stress level and the number of fatigue cycles of the material.

3.4 Tooth Surface Contact Fatigue Life Prediction Model

Through the static analysis of gear transmission by Ansys Workbench, the stress – strain characteristics of the gear meshing area during stable meshing transmission are studied. Based on the load changes under cyclic loading in gear transient dynamics and by comparing to determine the load scaling coefficient, in the SN fatigue (stress fatigue) module of ncode, the critical – plane method and rain – flow counting method are used to calculate the stress range and average stress, and combined with the Goodman equal – life average stress correction. Finally, the Palmgren – Miner linear damage accumulation theory is applied to predict the contact fatigue life, obtaining the number of cycles for failure initiation and the tooth surface area.

4. Simulation Results and Analysis

4.1 Contact Fatigue Life Analysis under Different Input Rotational Speeds

- Simulation Settings: The rotational speeds of the driving gear are set to 1200 r/min, 1500 r/min, and 1800 r/min respectively, and the load torque of the driven gear is set to 30,000 Nmm. Transient dynamics analysis is carried out to obtain the gear stress – time sub – step history. Then, by superimposing and comparing with the static analysis results of the load torque of 30,000 Nmm, the scaling coefficient is obtained, and the contact fatigue life is calculated. The fatigue life cloud diagrams at 1200 r/min, 1500 r/min, and 1800 r/min are obtained, mainly analyzing the driving gear, as shown in Figure 8.

- Analysis of Results: In the stress – history input, for the 1200 r/min condition, only one complete cycle of 0.05 s is input according to the relationship between its cycle and time, while for 1500 r/min and 1800 r/min, two complete cycles of 0.08 s and 0.0667 s are input respectively. Therefore, the number of cycles in the analysis of 1500 r/min and 1800 r/min needs to be converted, which are times and times respectively. The working life and dangerous nodes are shown in Table 3. It can be seen from Table 3 that under the same load torque, the rotational speed is negatively correlated with the number of cycles. This is because an increase in rotational speed leads to an increase in the fluctuation of the gear stress history, and the corresponding damage accumulation process is more rapid. At the same time, the higher the rotational speed, the shorter the working life, because the time for the gear to experience a complete cycle of stress is shorter. From the analysis results, it can be seen that the dangerous nodes mostly appear at the two ends of the pitch line on the tooth surface. On the same tooth – width direction, the stress at the two – end edge positions is greater than that at the center position.

4.2 Contact Fatigue Life Analysis under Different Load Torques

- Simulation Settings: The rotational speed is set to 2100 r/min, and the load torques are set to 30,000 Nmm, 60,000 Nmm, and 90,000 Nmm respectively. Transient dynamics analysis is carried out, and by superimposing and comparing with their respective static states, the scaling coefficients are generated, and the fatigue life cloud diagrams under different load torques are obtained, mainly analyzing the driving gear, as shown in Figure 9.

- Analysis of Results: The working life and dangerous nodes are shown in Table 4. It can be seen from Table 4 that the larger the load torque, the smaller the number of gear cycles. This is because an increase in load torque leads to an increase in input torque and contact stress. Compared with the analysis results in 3.1, it can be seen that: 1) The influence of load torque on the contact fatigue life is much greater than that of the input rotational speed; 2) For the actual use of aviation gears, if it is necessary to ensure a high working life under high – speed and heavy – load conditions, it is necessary to replace the material with a higher yield strength.

4.3 Contact Fatigue Life Analysis under Different Friction Coefficients

- Simulation Settings: The rotational speed is set to 1200 r/min, and the load torque is set to 30,000 Nmm. Gear transient dynamics analysis is carried out. The friction coefficients affected by different tooth surface roughnesses of 0.2μm, 0.4μm, and 0.6μm are set for gear static analysis to obtain the corresponding load scaling coefficients and the fatigue life cloud diagrams under different tooth surface roughnesses, mainly focusing on the driving gear, as shown in Figure 10.

- Analysis of Results: According to Table 5, the friction coefficient is positively correlated with contact fatigue. In the elastohydrodynamic lubrication state, a smaller friction coefficient indicates a larger oil film thickness between the tooth surfaces. However, an excessively large oil film thickness can cause an increase in the viscosity of the lubricating oil between the tooth surfaces, leading to an increase in the tooth surface contact pressure, which is consistent with the inferences in the literature. From the analysis results, it can be concluded that the influence of the tooth surface friction coefficient on the working life is relatively small, and the working life of gears in the elastohydrodynamic lubrication state is relatively high.

5. Conclusions

- A simulation model for gear contact fatigue life has been successfully established. This model enables the acquisition of contact fatigue lives under different input rotational speeds, load torques, and friction coefficients, as well as the identification of dangerous nodes where damage is most likely to occur. The model provides a powerful tool for predicting gear performance and evaluating gear reliability under various working conditions.

- The influence laws and amplitudes of the three influencing factors on the tooth surface contact fatigue life have been obtained. Through the prediction of dangerous node positions, it is found that the two ends of the gear along the tooth width direction are more prone to damage than the middle position. The simulation experimental data can serve as a valuable reference for gear contact strength assessment and subsequent fatigue tests. This research not only deepens the understanding of gear contact fatigue mechanisms but also provides practical guidance for improving gear design and manufacturing processes, ultimately contributing to the development of more reliable and efficient mechanical transmission systems.

6. Future Research Directions

Although this study has achieved certain results in the research of spur gear contact fatigue life under multiple working conditions, there are still some aspects that can be further explored:

- In – depth Study of Complex Working Conditions: In real – world applications, gears often operate under more complex working conditions, such as variable – speed and variable – load, and in harsh environments with temperature and humidity changes. Future research can focus on establishing more accurate models to simulate these complex conditions and study their combined effects on gear contact fatigue life.

- Consideration of Micro – structural Influences: The internal microstructure of gear materials has a significant impact on fatigue performance. Research can be carried out to incorporate micro – structural characteristics, such as grain size, phase composition, and residual stress, into the contact fatigue life model to more accurately predict the fatigue behavior of gears.

- Optimization of Gear Design Based on Fatigue Life: Using the research results of contact fatigue life, optimization algorithms can be applied to optimize gear parameters, such as tooth profile, tooth width, and material selection, to achieve the goal of maximizing gear contact fatigue life while meeting the requirements of transmission performance.

- Experimental Verification and Model Refinement: Conduct more in – depth experimental studies to verify the accuracy of the simulation model. Based on experimental results, the model can be further refined and improved to enhance its predictive ability and practical application value.