This article focuses on the simulation and analysis of the cutting contact area between the milling cutter and workpiece during spur gear milling. A comprehensive approach based on solid modeling technology is proposed, which includes establishing a mathematical model of the gear milling process, planning the tool path, simulating the cutting contact area using the solid method, and validating the method through experiments. The results show that this method can accurately predict the cutting contact area, providing a basis for optimizing gear milling parameters and improving machining quality.

1. Introduction

1.1 Background and Significance of Gear Milling

Gear milling is a crucial process in the manufacturing of gears, widely used in various industries such as automotive, aerospace, and machinery. The quality of gear milling directly affects the performance and reliability of mechanical equipment. In recent years, with the increasing demand for high – precision and high – performance gears, the research on gear milling technology has become more and more important.

| Industry | Application of Gears | Requirements for Gear Milling |

|---|---|---|

| Automotive | Transmission systems | High precision, low noise |

| Aerospace | Aircraft engines, landing gear systems | High strength, high precision |

| Machinery | Industrial machinery, machine tools | Durability, accurate transmission |

1.2 Research Status of Gear Milling and Cutting Contact Area Calculation

Currently, research on gear milling mainly focuses on tool path planning. Many scholars have proposed different methods to improve the surface accuracy of gears from a geometric perspective. However, the determination of machining parameters is also affected by physical factors such as cutting force. Calculating the cutting contact area accurately is the basis for predicting cutting force. There are three main methods for calculating the cutting contact area: the solid method, the discrete method, and the analytical method, each with its own advantages and disadvantages.

| Method | Principle | Advantages | Disadvantages |

|---|---|---|---|

| Solid Method | Determine the cutting contact area through Boolean operations between the solid models of the tool and the workpiece | High calculation accuracy, suitable for three – axis machining, can meet simulation requirements | – |

| Discrete Method | Judge whether the discretized tool and workpiece intersect to determine the cutting contact area | High calculation efficiency | Low calculation accuracy due to discretization, difficult to balance efficiency and accuracy |

| Analytical Method | Represent the cutting contact area with space curves and solve through dimensionality reduction methods | High calculation efficiency under certain accuracy requirements | Complex calculation process for spur gear milling, poor adaptability to different working conditions |

1.3 Objectives and Main Content of This Research

The objective of this research is to propose an effective method for simulating and analyzing the cutting contact area between the milling cutter and workpiece in spur gear milling. The main content includes establishing a mathematical model of the gear milling process, planning the tool path based on the equal – residual height method, simulating the cutting contact area using the solid method, and verifying the accuracy and effectiveness of the method through experiments.

2. Mathematical Model of the Gear Milling Process

2.1 Definition of Coordinate Systems

To accurately describe the relative position relationship between the milling cutter and the workpiece during gear milling, three coordinate systems are established: the workpiece coordinate system , the feed coordinate system , and the tool coordinate system .

| Coordinate System | Origin | Axes Definition | Relationship with Others |

|---|---|---|---|

| Located at the center of rotation of the upper end face of the gear | coincides with the centerline of the tooth profile, coincides with the gear axis | The reference coordinate system for describing the workpiece geometry and tool movement | |

| Located at the center of the ball – end milling cutter | is the normal direction of the ideal involute surface, is parallel to the gear axis | Used to describe the tool feed movement, related to by coordinate transformation | |

| Coincides with the origin of (fixed at the tool ball center) | coincides with the tool axis, positive in the direction away from the workpiece surface | Obtained by rotating around its own axis, used to calculate cutting contact angles |

2.2 Transformation Matrices

The transformation matrices between the coordinate systems are used to convert the coordinates of points in different coordinate systems. The homogeneous coordinate transformation matrix from to , from to , and from to are derived. These matrices play an important role in calculating the position of the cutting contact area in different coordinate systems.

| Transformation Matrix | Formula | Significance |

|---|---|---|

| Transforms coordinates from to , related to the tool deflection angle | ||

| Complex formula considering rotation and translation | Transforms coordinates from to , including rotation and translation information | |

| Directly transforms coordinates from to |

2.3 Mathematical Model of the Workpiece Tooth Profile to be Processed

For spur gears, the surface of the workpiece to be processed is an involute offset surface, which can be represented as a geometric body formed by stretching the tooth profile along the axis. The coordinates of points on the involute tooth profile and the normal vector are derived, and then the equation of the workpiece tooth profile to be processed considering the machining allowance is obtained.

| Parameter | Formula | Explanation |

|---|---|---|

| Coordinates of points on involute tooth profile | : base circle radius; : pressure angle; : central angle corresponding to the base circle tooth thickness; | |

| Normal vector of involute tooth profile | Used to describe the direction perpendicular to the tooth profile | |

| Equation of workpiece tooth profile to be processed | : semi – finishing allowance |

3. Tool Path Planning

3.1 Comparison of Tool Path Planning Methods

There are two main methods for gear milling tool path planning: the free – surface envelope method and the involute envelope method. The free – surface envelope method fits the gear involute surface into a free surface and uses the CAM software’s surface milling function to plan the tool path. The involute envelope method regards the involute as the envelope line formed by the ball – end milling cutter at the tool position. The involute envelope method has higher calculation accuracy and efficiency as it unifies the geometric characteristics of the tooth profile, accuracy requirements, and tool parameters.

| Method | Principle | Advantages | Disadvantages |

|---|---|---|---|

| Free – surface Envelope Method | Fit the gear involute surface into a free surface and use CAM software for tool path planning | Automatic planning by CAM software | Potential accuracy loss due to free – surface construction |

| Involute Envelope Method | Regard the involute as the envelope line of the ball – end milling cutter | High calculation accuracy, unifies tooth profile, accuracy, and tool parameters, high planning efficiency | – |

3.2 Tool Path Planning Based on the Equal – Residual Height Method

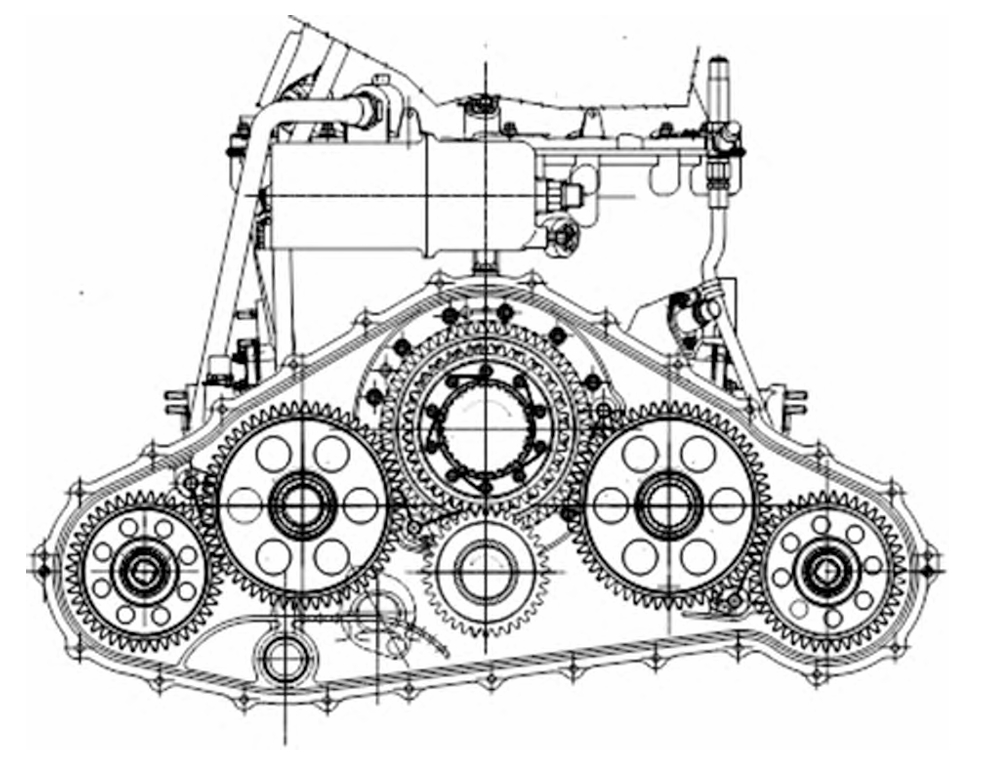

This article adopts the involute envelope method based on the equal – residual height to plan the tool path. By establishing the relationship between the initial tool position, the residual height, and the tooth profile, the tool position points are calculated iteratively. As shown in Figure [figure number], the points and are calculated through specific geometric relationships to complete the tool path planning in the tooth height direction.

[Insert a figure here showing the geometric relationship for calculating tool position points, with clear labels for each point and curve]

| Step | Formula | Explanation |

|---|---|---|

| Calculate | : residual height, used to determine the position of the residual height point | |

| Calculate | : tool radius, based on the geometric relationship between the tool and the tooth profile |

4. Simulation Calculation Process of the Cutting Contact Area by the Solid Method

4.1 Overall Process of the Solid Method

The solid method for simulating the cutting contact area in spur gear milling includes several steps: generating tool position points, generating the tool swept volume, updating the workpiece during the cutting process, identifying the cutting contact area, calculating the cutting contact angles, and determining whether all tool path cutting contact areas have been extracted.

| Step | Operation | Explanation |

|---|---|---|

| Generate tool position points | Calculate according to tool, workpiece, and cutting parameters, combined with the involute tooth profile model and equal – residual height method | Provide positions for subsequent operations |

| Generate tool swept volume | Construct the tool swept surface, the cutting – in part, and the cutting – out part of the tool rotation surface at different tool position points, and then sew them | Represent the volume swept by the tool during cutting |

| Update workpiece during cutting process | Perform a Boolean subtraction operation between the tool swept volume and the workpiece geometric entity model | Reflect the material removal during cutting |

| Identify cutting contact area | Find the spherical – geometric – characteristic surface centered at the tool position point from the updated workpiece | Determine the area where the tool contacts the workpiece |

| Calculate cutting contact angles | Use a set of planes parallel to the tool axis to intersect the spherical surface representing the cutting contact area | Obtain the cutting – in and cutting – out angles of the tool |

| Determine whether all tool path cutting contact areas have been extracted | Check if all tool paths have been processed | Control the overall simulation process |

4.2 Key Steps and Their Significance

- Generating the Tool Swept Volume: This step is crucial as it accurately represents the space occupied by the tool during the cutting process. By constructing the tool swept surface, cutting – in part, and cutting – out part, and then sewing them together, we can get a complete tool swept volume model, which is the basis for subsequent material removal simulation.

- Cutting Contact Area Identification: Based on the fact that the cutting contact area is a part of the spherical surface when using a ball – end milling cutter for finishing, we can identify the cutting contact area from the updated workpiece. This identification method takes advantage of the geometric characteristics of the tool and workpiece, ensuring the accuracy of the cutting contact area determination.

- Cutting Contact Angle Calculation: Calculating the cutting – in and cutting – out angles is important for understanding the cutting process. These angles can affect the cutting force distribution and the quality of the machined surface. By using planes parallel to the tool axis to intersect the spherical surface of the cutting contact area, we can accurately calculate these angles.

4.3 Optimization of the Simulation Process

In the simulation process, it is found that for the same tool position point, when only the tool deflection angle changes, the cutting contact areas under different tool postures have the same geometric characteristics. Therefore, we can use the surface segmentation method to calculate the new cutting contact angle interval in the tool coordinate system of the new tool posture, reducing the time consumption caused by repeated calculations.

5. Simulation Examples and Experimental Verification

5.1 Experimental Processing and Measurement Devices

The gear milling experiment uses a five – axis machining center (DMG DMU50). The B – axis is fixed, the C – axis rotates to achieve workpiece indexing and tool deflection angle setting, and the X, Y, and Z axes move linearly for tool positioning and cutting. The workpiece material is [material name], and the tool is a solid carbide ball – end milling cutter with specific parameters. The cutting contact area boundary curve is measured by a 19JPC – V digital universal tool microscope.

| Equipment | Function | Parameters |

|---|---|---|

| Five – axis machining center (DMG DMU50) | Perform gear milling | B – axis fixed; C – axis for indexing and tool deflection angle setting; X, Y, Z axes for tool positioning and cutting |

| Workpiece | Object of machining | Material: [material name]; Gear modulus , 齿数 , 分度圆压力角 , 齿顶高系数 , 顶隙系数 |

| Tool | Cut the workpiece | Solid carbide ball – end milling cutter, radius , 齿数 , 螺旋角 , 主轴转速 , 每齿进给量 [value], 刀具偏角 , 齿廓残留高度 , 齿廓半精加工余量 |

| 19JPC – V digital universal tool microscope | Measure the cutting contact area boundary curve | Measurement plane coordinate system parallel to the measurement worktable and ‘s plane |

5.2 Comparison between Experimental Results and Simulation Analysis Results

The measurement results of tool paths 2 and 4 are compared with the simulation results. As shown in Figure [figure number], the actual measurement results of curves and are basically consistent with the simulation results. Although curve is blurred on the actual workpiece surface due to workpiece slip deformation, the measurement results of points , , and their adjacent points are consistent with the simulation results, indicating a certain degree of agreement between the experimental and simulation results. The small errors in the cutting contact area boundary curve are mainly caused by measurement errors and workpiece surface plastic deformation.

[Insert a figure here showing the comparison of cutting contact area boundary curves between experimental and simulation results, with clear legends for each curve]

| Curve | Experimental Result | Simulation Result | Error Analysis |

|---|---|---|---|

| Consistent with simulation result | Matches the experimental measurement | – | |

| Consistent with simulation result | Matches the experimental measurement | – | |

| Blurred on the actual workpiece surface, but adjacent points’ measurement results are consistent with simulation | Matches the experimental measurement in adjacent points | Error due to workpiece slip deformation and measurement error |

The cutting – in and cutting – out angles calculated by simulation for tool paths 2 and 4 are also presented, which further verifies the accuracy of the simulation method.

6. Conclusion

6.1 Summary of Research Results

This article proposes a simulation analysis method for extracting the instantaneous cutting contact area between the ball – end milling cutter and the workpiece in the multi – axis finishing milling of cylindrical spur gears based on solid modeling technology. The main research results include: constructing a tool path planning method based on the equal – residual height method, realizing material removal in the spur gear milling process through the Boolean operation between the tool swept volume and the workpiece, accurately identifying the cutting contact area, and verifying the effectiveness and accuracy of the method through experiments.