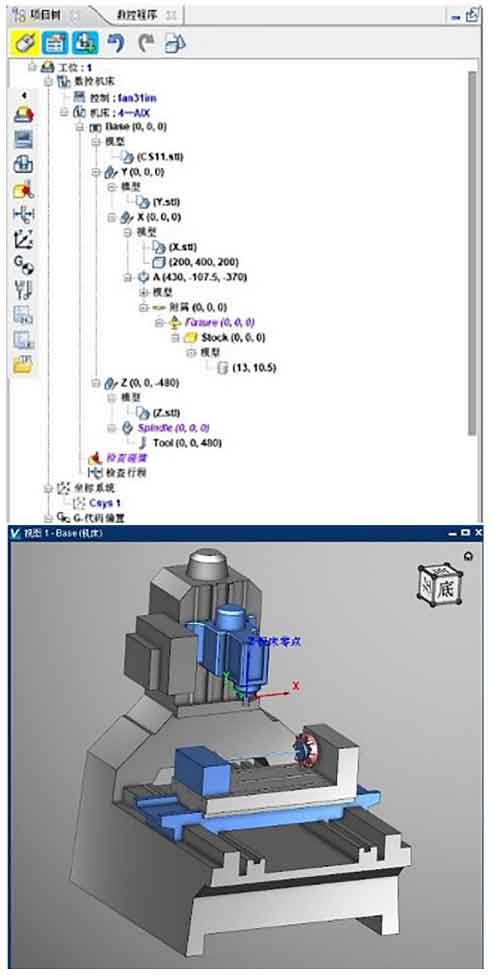

Vericut is a powerful simulation processing software, which can build the geometric dimensions of the machine tool, blank and other parts in the original proportion. During the simulation process, it can automatically detect the error information such as interference and over-cutting between the machine tool and parts, and prompt in the information column and log file. Users can reconstruct the machine tool and tool or optimize the NC program according to the prompt information. At the same time, Vericut software includes FANUC, SIEMENS HEIDENHAIN and other control system files can be selected. NC simulation processing before machine tool processing can reduce processing accidents caused by unreasonable design and other reasons. At the same time, users can use the program optimization function provided by the software to improve processing efficiency. The topological relationship and model of the gear milling machine tool structure are shown in Figure 1.

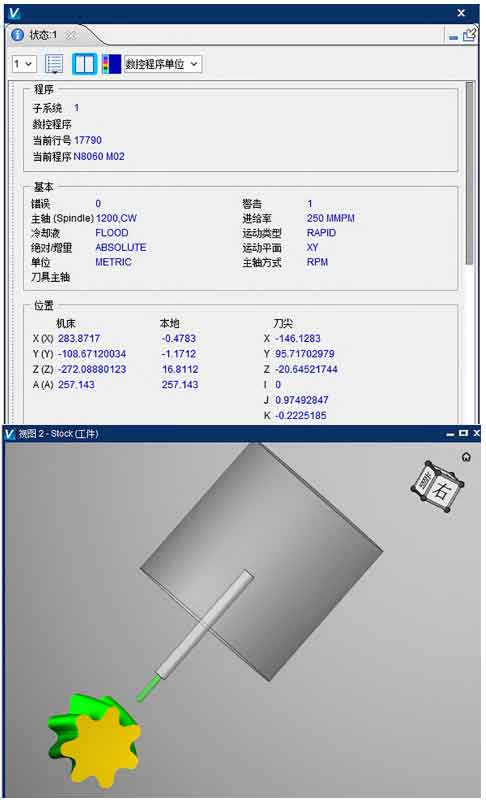

In the process of simulation machining of double-arc helical gears, the numerical control milling machine model is imported into Vericut 9.2, and the fan31im.ctl file is selected as the control system of the milling machine according to the machining needs. Add a part blank under the corresponding structure of the project tree. The added tool is the created ball-end milling cutter. The ball-end diameter is φ 2 mm, the blade length is 20 mm, set the machining coordinate system, add the NC program output by the UG post-processor to the NC program, and click the Start button to simulate machining after various simulation conditions are set. Vericut software provides a good visual processing process. Before processing, open the status window to monitor the error of the processing process. The status window information and workpiece view during processing are shown in Figure 2.

According to the status monitoring window and log file, there are no warnings such as collision and over-cutting during the simulation processing, which confirms the correctness of the NC program and the simulation processing.