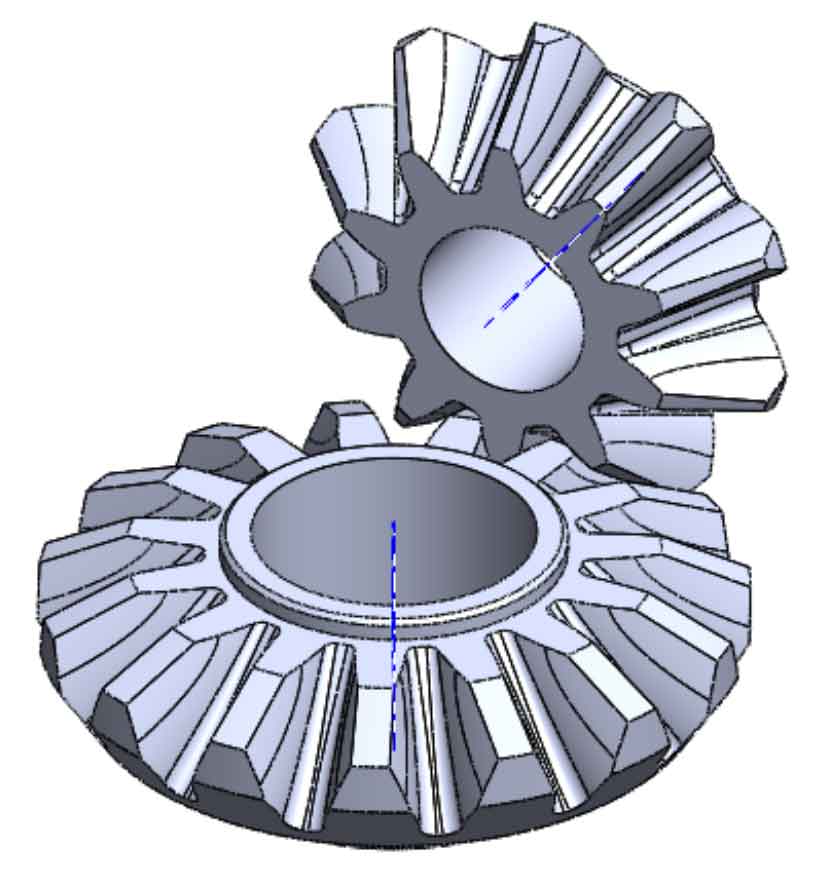

The process of gear cutting of straight bevel gear blank is actually the process that the material in the tooth groove of straight bevel gear blank is gradually removed. This is a dynamic process. In the finite element analysis of ABAQUS, it is necessary to simulate this dynamic process in stages. In this paper, the “life and death element” technology of the “interaction” module in the finite element software is used to simulate the cutting process of straight bevel gear blank material.

When the finite element software uses the “life and death element” technology, the relevant element attribute quantity of the element set as “dead” will be multiplied by a very small reduction factor of an order of magnitude. At this time, although these elements do not disappear, the value of their attribute value multiplied by the reduction factor is almost zero, which is equivalent to being “killed” in the calculation of subsequent finite element analysis steps. Therefore, in the finite element analysis of the gear cutting simulation of the straight bevel gear split billet, the reasonable use of the “life and death element” technology can more vividly simulate the gear cutting process of the straight bevel gear split billet, which is conducive to more accurate and fast analysis of the influence of the internal stress redistribution of the straight bevel gear split billet on the deformation of the straight bevel gear billet.

Before using the “life and death element” technology in the finite element software, the part of the element that needs to be “killed” in the finite element model should be separated from other elements. In the process of simulating gear cutting, the units to be removed each time will be “killed” in the corresponding analysis step. Multiple analysis steps can be created for the machining of multiple tooth slots of straight bevel gear blank. Adjusting the “kill” sequence of units in ABAQUS software can achieve the simulation effect of various process sequences.