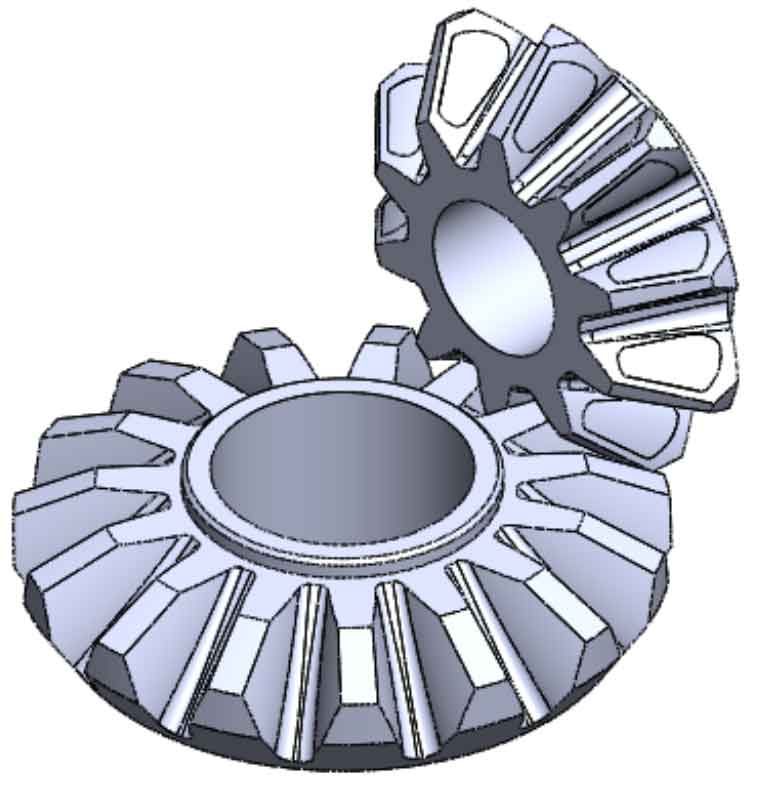

The deformation of extra large split spur bevel gear blank in the process of gear cutting is closely related to the instantaneous stress distribution of spur bevel gear blank. Therefore, the stress evolution analysis should be carried out through finite element simulation, and the stress state of the surface and internal section of the spur bevel gear blank should be extracted to explore the stress evolution law of the spur bevel gear blank in the whole machining process.

The finite element model of spur bevel gear blank with initial stress field is established by using ABAQUS software. The tooth cutting process of spur bevel gear blank is simulated by using “life and death element” technology. After finite element simulation and analysis, the stress distribution on the surface and internal materials of spur bevel gear blank in the machining process can be obtained.

By analyzing the results of stress evolution of spur bevel gear blank, it can be seen that the stress in X direction changes greatly during the processing of spur bevel gear blank, and the stress in X direction on the surface and inside of spur bevel gear blank changes obviously; The stress change in Y direction is mainly reflected in the surface of the wheel blank, and the stress change in Y direction in the interior of the spur bevel gear wheel blank is small; In the process of machining, the tensile stress in Z direction will also be generated in the interior of the wheel blank, but the value of the stress is small.

Therefore, it can be analyzed that the x-direction stress of spur bevel gear blank changes greatly in gear cutting, and the change of X-direction stress of spur bevel gear blank is the main reason for the deformation of split gear.