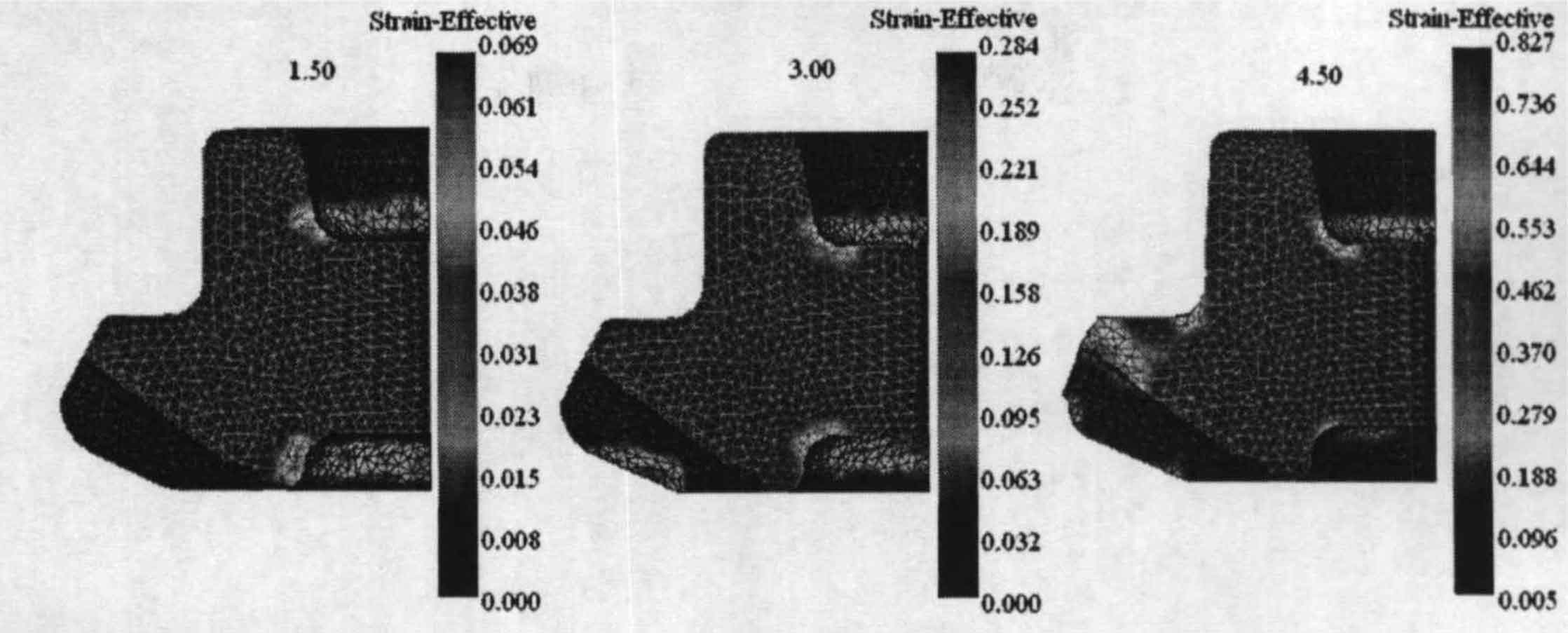

The strain distribution in the deformation process shows that the overall deformation of the half shaft gear is small, and mainly concentrated on the tooth surface, the large end face and the transition fillet of the upper and lower bosses. Figure 1 shows the strain distribution when the reduction is 1.5mm, 3.0mm and 4.5mm respectively. At the initial stage of deformation, only a small amount of deformation occurs at the transition fillet of the upper and lower boss end faces, and other parts are basically not deformed. With the filling of the addendum of the half shaft gear, a large strain begins to occur at the addendum, which indicates that the metal deformation at this part is large. At the later stage of forming, the tooth cavity is full, and the strain on the end face and tooth surface reaches the maximum.

The distribution of strain rate in the deformation process shows that the larger strain rate is mainly distributed in the transition areas between the contact surface between the half shaft gear and the die and the free surface of the half shaft gear, especially those that will contact the die cavity in the next step. Figure 2 shows the strain rate distribution when the reduction is 1.5mm, 3.0mm and 4.5mm respectively.