With the continuous progress of agricultural mechanization, a large number of heavy tractors are used in the process of agricultural production and play an important role in the process of large-scale production. With the continuous increase of tractor tonnage, the volume of various tractor parts is becoming larger and larger, and the structure is becoming more and more complex, which has higher and higher requirements for manufacturing materials and processing technology.

As shown in Figure 1, the gear is an important transmission part of the tractor, and its performance has a great impact on the dynamic performance of the tractor. The processing process can be optimized by simulation.

There are many processing procedures for tractor gears. Generally, there are at least a dozen processes. The time required for each process is different. In the mass production and processing of tractor gears, if the processing procedures of tractor gears are reasonably arranged, it can save a lot of processing time, reuse processing machinery and improve processing efficiency.

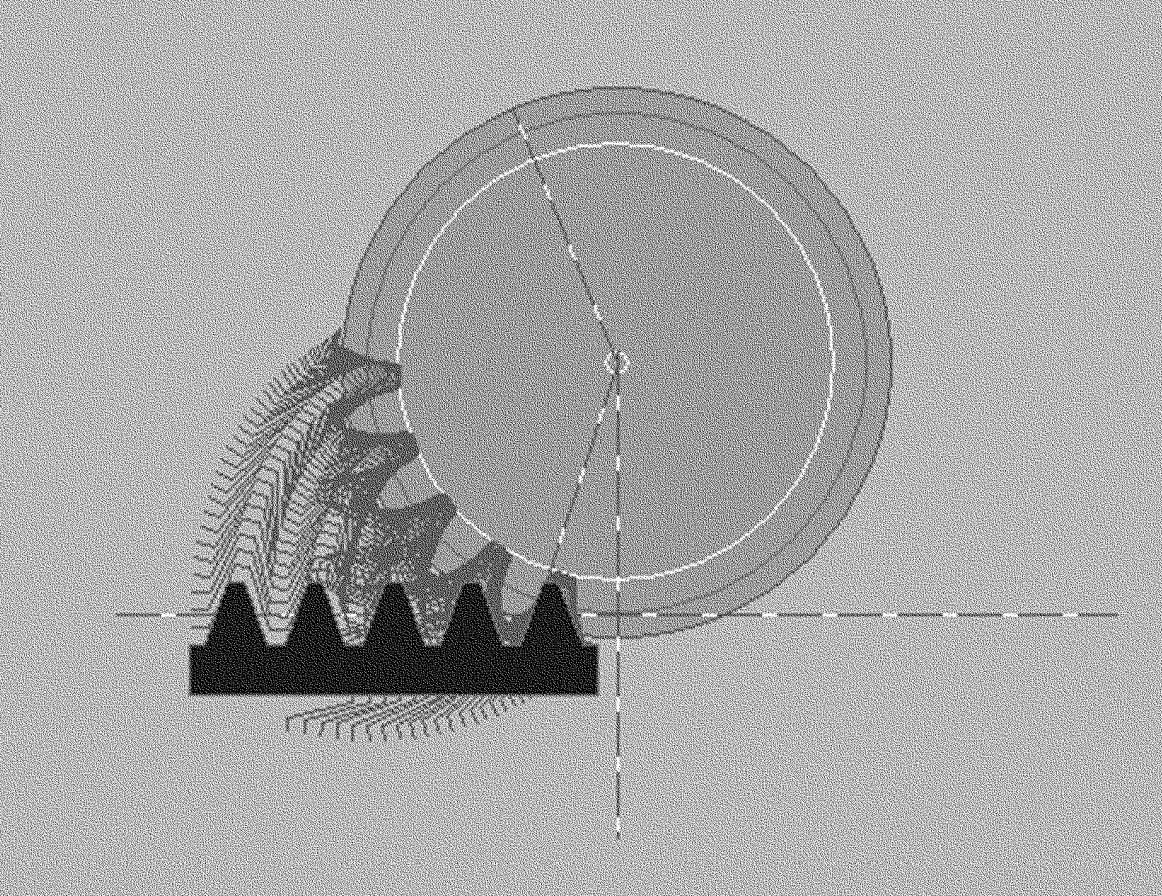

The processing simulation of tractor gear can count the time required for tractor gear processing, so as to obtain the processing efficiency of tractor gear, as shown in Figure 2. In the simulation of tractor gear machining, various parameters of tractor gear machining can be set. Finally, the time required for the whole process of tractor gear machining can be obtained by iterative calculation method.

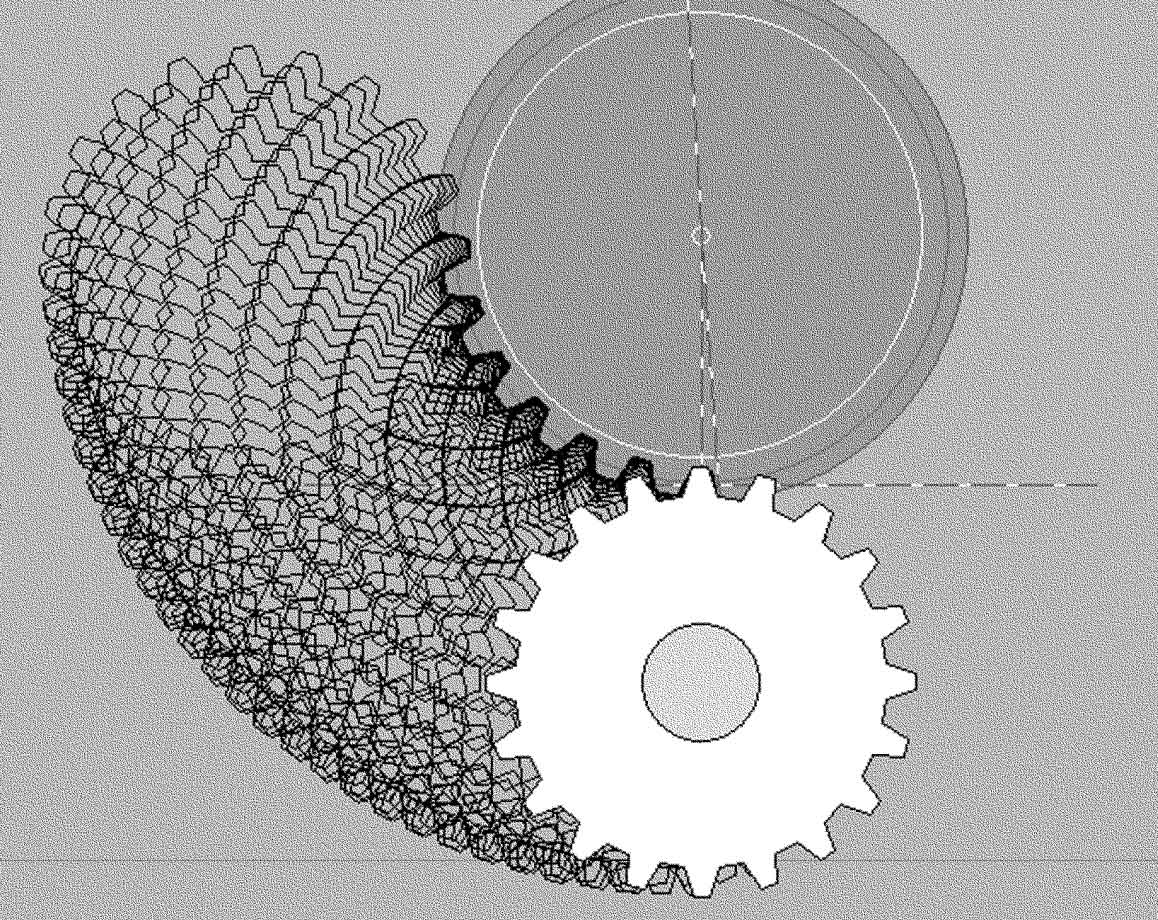

As shown in Figure 3, the process of machining tractor gears with rack tools is obtained through simulation. The time of the whole machining process is counted through simulation calculation, and the machining time required before and after batch tractor gear machining process optimization is compared. The results show that the total machining time can be significantly shortened by using ant colony algorithm.

In order to further verify the effect of ant colony algorithm on tractor gear processing optimization, the process of tractor gear processing with gear processing tools is simulated, as shown in Figure 4. The simulation results show that the ant colony algorithm can shorten the total time of processing Tractor gears by gear cutter. Because there are many processing procedures of tractor gears, the processing procedures can be adjusted reasonably in batch production and various processing machines can be used more fully, so as to shorten the waiting time in batch production of the next process and improve the processing efficiency of the whole process.