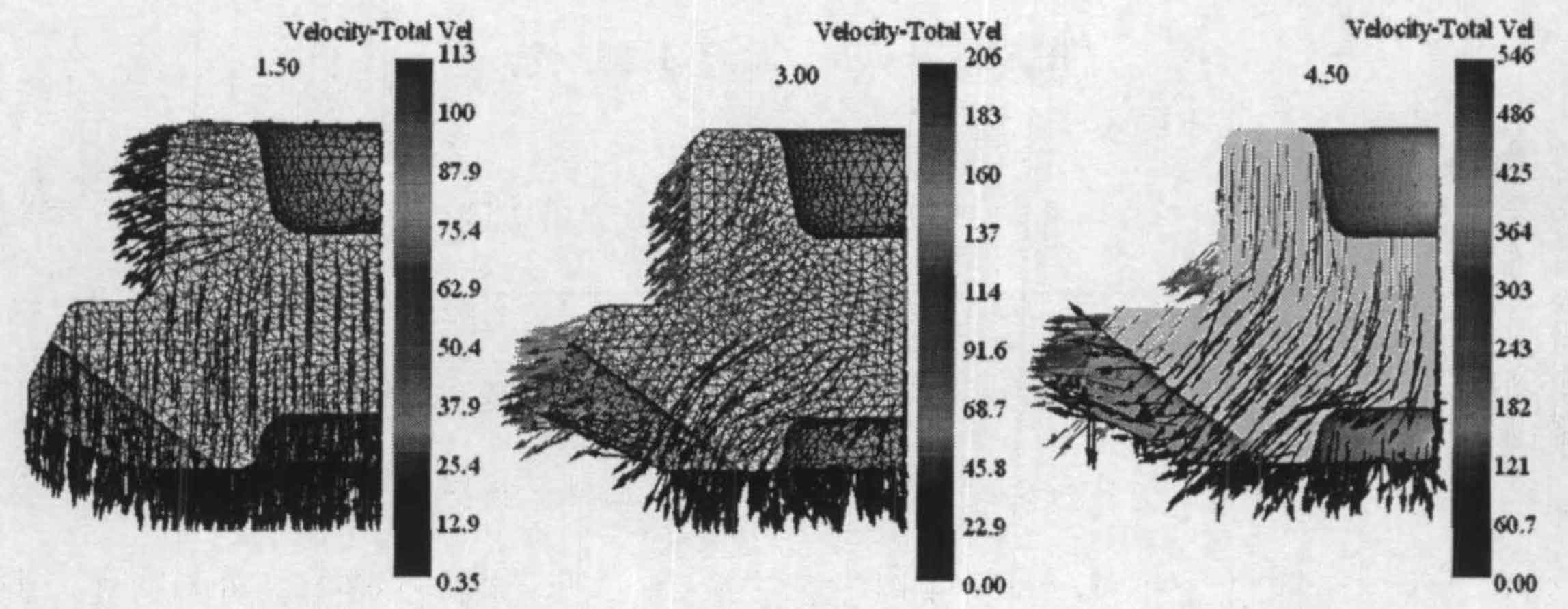

The velocity field distribution in the deformation process directly shows the metal flow law during the final forging of half shaft gear. As shown in the figure, the velocity field distribution is given when the reduction is 1.5mm, 3.0mm and 4.5mm respectively. At the initial stage of deformation, the metal mainly flows downward under the action of the upper and lower bosses. When the reduction reaches a certain value, the tooth top of the workpiece first contacts with the tooth die, and the metal begins to fill the tooth cavity under the action of the half shaft gear tooth die.

As the metal filled in the top of the half shaft gear begins to flow, part of the metal continues to move downward to fill the lower end face and tooth root, and the other part of the metal begins to flow radially to the back cone. At the later stage of forming, the tooth cavity of half shaft gear is basically full, and the metal mainly flows to the back cone to form flash.