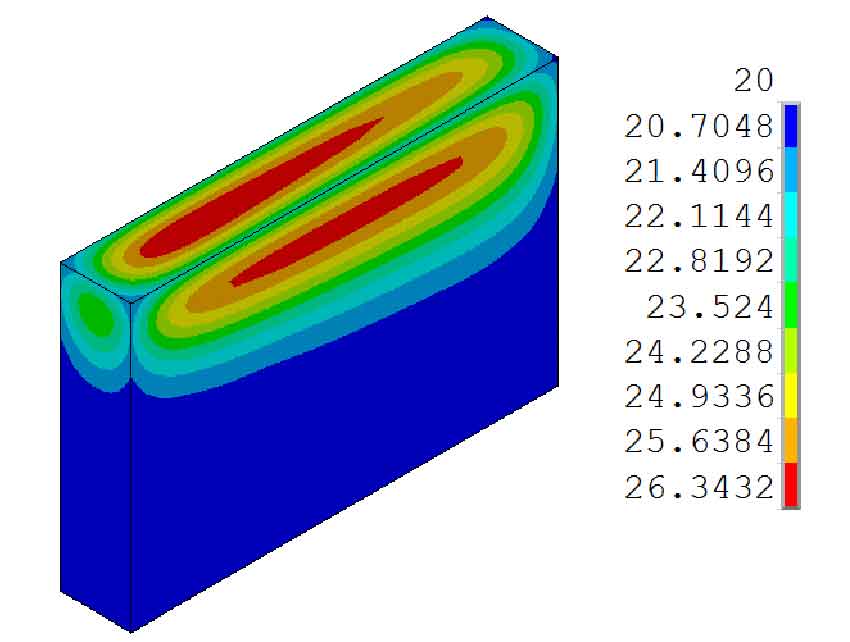

With grinding speed vs = 20.3 M / s and grinding depth AP = 50 μ m. The speed of bevel gear steel VW = 1200 mm / min is the standard. After the grinding simulation process, set the cooling time of 30s. By virtue of the heat conduction of the bevel gear steel, the surface temperature of the bevel gear steel is close to the normal temperature. The distribution of temperature field at this time is shown in Figure 1:

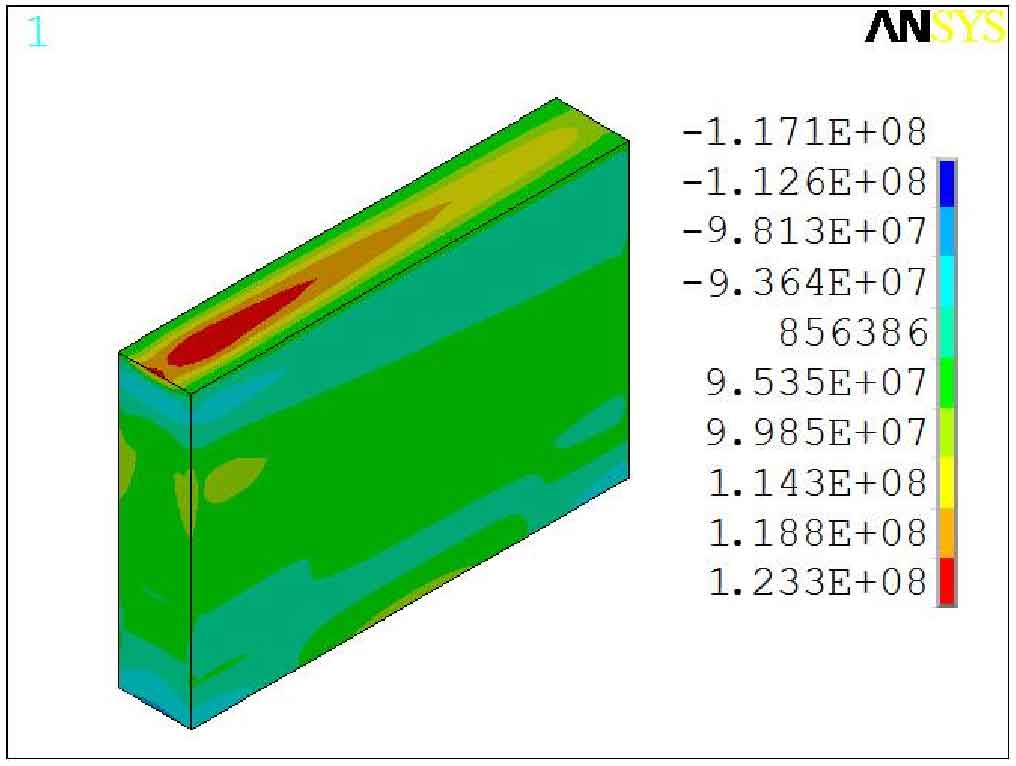

It can be considered that the stress state at this time is the residual stress of bevel gear steel. After the stress field simulation based on stress thermal coupling is completed, the residual stress distribution on the surface of the whole bevel gear steel can be observed by looking at the stress cloud diagram. The direction of the stress is x direction, i.e. vertical grinding direction. The residual stress distribution at this time is shown in Figure 2.

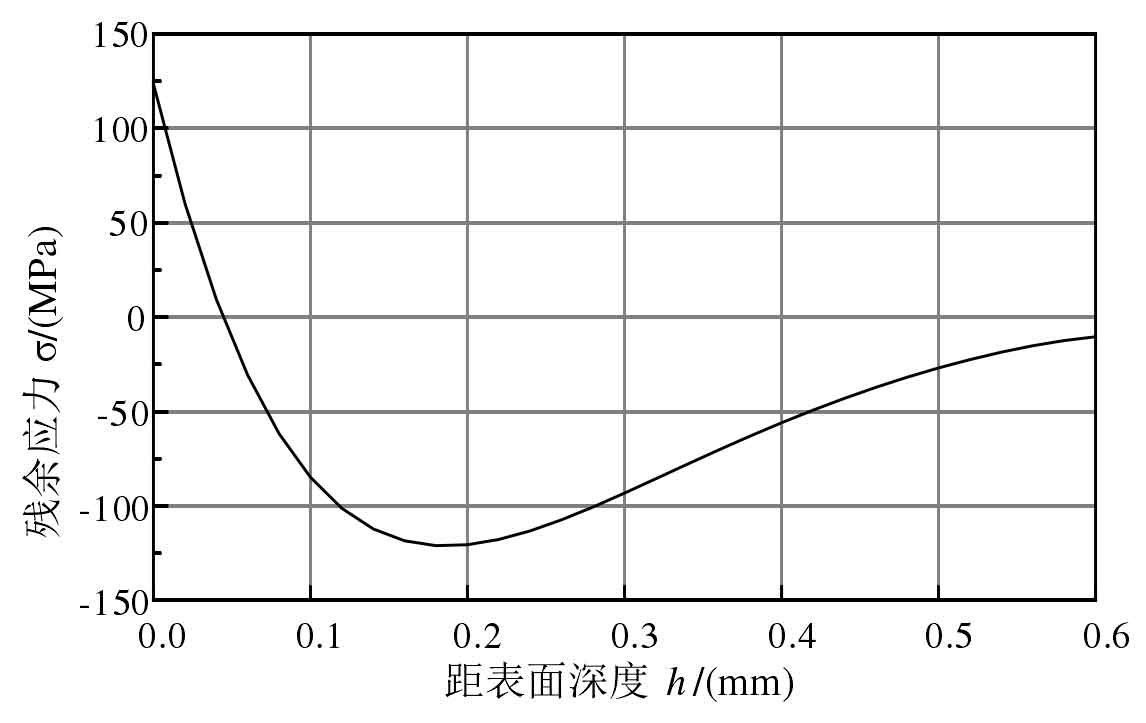

It can be seen from Figure 2 that after the grinding process of bevel gear steel, the surface is in a state of tensile stress, and the maximum value of residual tensile stress is about 123 MPa. Further investigate the distribution state of residual stress along the layer depth, set a path perpendicular to the grinding surface of bevel gear steel along the section in the middle area of the model (10mm away from the cutting distance), and obtain the variation trend diagram of residual stress at different depths of the surface. Its distribution is shown in Figure 3.

It can be seen from Figure 3 that with the increase of the depth from the surface, the value of the residual tensile stress gradually decreases, changes to the residual compressive stress at the depth of about 0.05 mm, and reaches the maximum value at 0.19 mm. The value of the maximum residual compressive stress is about 119.6 MPa. With the increase of depth, the value of compressive stress gradually decreases and tends to zero.