1. Introduction

Magnetic gears have gained significant attention in various fields due to their numerous advantages over traditional mechanical gears. The field – modulated magnetic gear (FMMG), in particular, offers features such as high torque density, overload protection, low vibration, and low noise. However, the traditional rectangular magnetic modulation block in magnetic gears leads to large eddy – current losses at high speeds. To address this issue, a new type of magnetic gear with a sinusoidal magnetic modulation ring is proposed in this study.

1.1 Background of Magnetic Gears

Magnetic gears operate based on the principle of magnetic field modulation. The interaction between the magnetic fields of the permanent magnets in the inner and outer rotors, along with the modulation effect of the magnetic modulation ring, enables torque transfer. Different from mechanical gears, magnetic gears have no physical contact, which reduces wear and tear and eliminates the need for lubrication. This makes them suitable for applications in harsh environments, such as aerospace and underwater systems.

1.2 Motivation for the Study

The existing rectangular magnetic modulation block magnetic gears face challenges in high – speed operation. The large eddy – current losses not only reduce the efficiency of the gear but also cause potential problems like high – temperature demagnetization. The sinusoidal magnetic modulation ring magnetic gear is expected to overcome these issues. To accurately analyze the performance of this new type of magnetic gear, the magnetic network method is introduced. This method can handle complex geometric structures and is more efficient in calculating the magnetic field distribution compared to some traditional methods.

2. Topology Structure of the New Modulated Magnetic Gear

2.1 Structure of the Rectangular Magnetic Modulation Ring Magnetic Gear

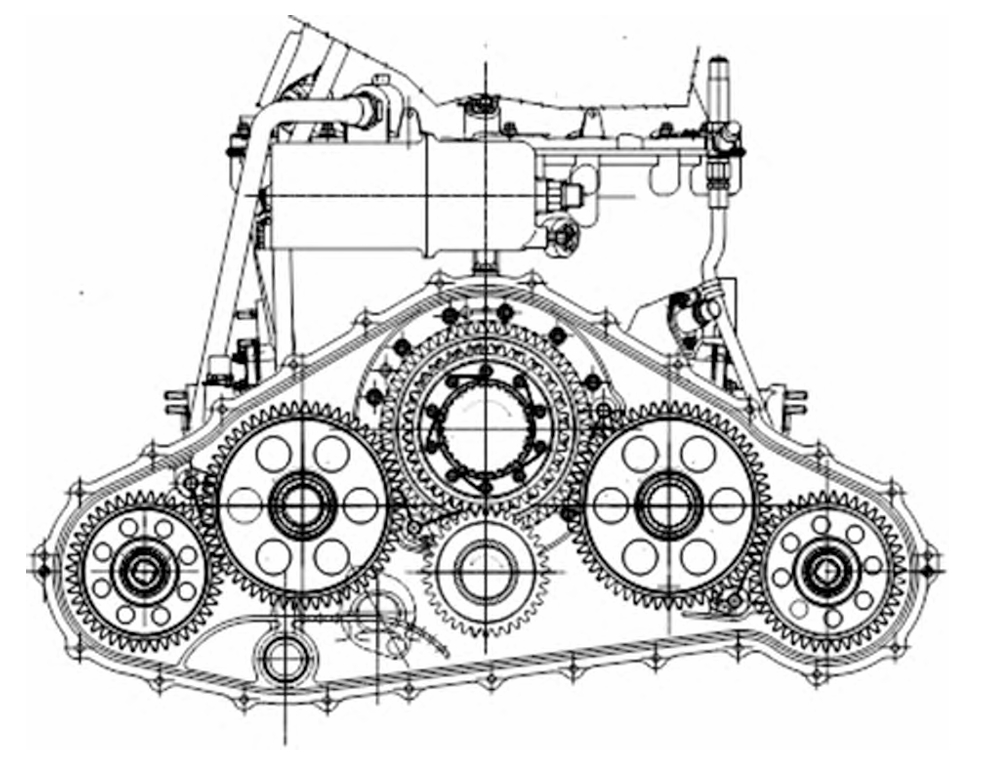

The rectangular magnetic modulation ring magnetic gear, as shown in Figure 1(a), consists of an inner rotor with permanent magnets, an outer rotor, and a rectangular magnetic modulation block. When the magnetic field passes through the rectangular modulation block, it generates many ineffective harmonics. These harmonics result in increased eddy – current losses during high – speed operation, which can lead to overheating and a decrease in the performance of the gear.

| Component | Function |

|---|---|

| Inner Rotor Permanent Magnets | Generate the magnetic field for torque transfer |

| Outer Rotor | Transmit the torque output |

| Rectangular Magnetic Modulation Block | Modulate the magnetic field between the inner and outer rotors |

2.2 Structure of the Sinusoidal Magnetic Modulation Ring Magnetic Gear

The proposed sinusoidal magnetic modulation ring magnetic gear, depicted in Figure 1(b), has a more sophisticated design. The inner rotor has 28 pairs of permanent magnet poles, the outer rotor has 1 pair of poles, and the modulation ring is composed of 29 ferromagnetic materials with a sinusoidal profile arranged circumferentially. This structure can adjust the air – gap thickness between the inner and outer rotors, making the air – gap permeance waveform a single sine wave. As a result, it significantly reduces the content of ineffective harmonics in the magnetic field.

| Component | Feature |

|---|---|

| Inner Rotor | 28 pairs of permanent magnet poles |

| Outer Rotor | 1 pair of poles |

| Sinusoidal Magnetic Modulation Ring | Composed of 29 ferromagnetic materials with a sinusoidal profile |

3. Establishment and Solution of the Magnetic Network Model

3.1 Basic Principle of the Magnetic Network Method

The magnetic network method draws inspiration from electrical network theory. It simplifies the complex magnetic field problem by treating the magnetic field as a magnetic circuit. The complex geometric structure of the magnetic gear is discretized into a series of magnetic resistance units. Each unit has a constant magnetic flux within each iteration step, and the magnetic flux changes during the iterative process. By setting the material properties of each magnetic resistance unit and applying Ohm’s law and Kirchhoff’s laws in the magnetic circuit, a set of non – linear magnetic network equations can be established. Solving these equations yields the magnetic flux at each node, which further enables the calculation of the air – gap magnetic flux density for subsequent magnetic field and torque analysis.

3.2 Model Construction

3.2.1 Simplifying Assumptions

To facilitate the calculation of the magnetic network model, several assumptions are made:

- The magnetic resistance units are approximated as rectangular, ignoring the impact of their actual shape.

- The magnetic field is considered to be invariant along the axial direction, meaning it can be analyzed in a two – dimensional cross – section.

- The material properties of the magnetic resistance units are assumed to be constant, without considering the influence of time and temperature factors.

3.2.2 Layer Division of the Magnetic Gear

Based on the different materials in the magnetic gear, it can be divided into seven layers along the radial direction, as shown in Figure 2. These layers include the outer rotor core, outer permanent magnet, outer air – gap, magnetic modulation ring, inner air – gap, inner permanent magnet, and inner permanent magnet core.

| Layer | Material | Function |

|---|---|---|

| Outer Rotor Core | Ferromagnetic material | Provide a magnetic path for the outer rotor |

| Outer Permanent Magnet | Permanent magnetic material | Generate the magnetic field for the outer rotor |

| Outer Air – Gap | Air | Separate the outer rotor and the modulation ring |

| Magnetic Modulation Ring | Ferromagnetic material (sinusoidal profile) | Modulate the magnetic field between the inner and outer rotors |

| Inner Air – Gap | Air | Separate the inner rotor and the modulation ring |

| Inner Permanent Magnet | Permanent magnetic material | Generate the magnetic field for the inner rotor |

| Inner Permanent Magnet Core | Ferromagnetic material | Provide a magnetic path for the inner rotor |

3.2.3 Division of the Sinusoidal Magnetic Modulation Ring

The sinusoidal magnetic modulation ring, due to its complex shape, is divided using a specific method. As shown in Figure 3, it is decomposed into numerous regular – shaped rectangular units. Radially, it is divided into 6 layers, and circumferentially, it is divided into 16 layers. The magnetic resistance of each unit in the modulation ring is calculated based on the geometric parameters of the ferromagnetic and non – ferromagnetic components. For example, the magnetic resistance formula for each magnetic resistance unit in the sinusoidal magnetic modulation ring .

where , is the magnetic permeability of the ferromagnetic material, is the magnetic permeability of air, and are the cross – sectional areas of the ferromagnetic material and air in the modulation ring magnetic resistance unit respectively, and and are the lengths of the ferromagnetic material and air in a single magnetic resistance unit.

3.3 Generation of Magnetic Network Equations

3.3.1 Equivalent Magnetic Potential Source

The entire magnetic gear structure is classified into active and passive regions based on the ability of magnetic resistance units to generate magnetic potential sources. For a magnetic gear excited by permanent magnets, the magnetic potential source of the magnetic resistance unit is calculated by the formula:

where is the coercive force of the permanent magnet, and is the length of the magnetic resistance unit in the magnetic flux direction. For a magnetic gear with a radial magnetization method, the magnetic potential sources are divided into two directions, P and Q, and their calculation expressions are:

where the arc length of the permanent magnet is approximately represented by the product of the angle and the radius.

3.3.2 Equivalent Magnetic Resistance

Considering the influence of direction on magnetic resistance, the magnetic resistance expressions in the radial (P) and circumferential (Q) directions of the magnetic resistance unit are as follows:

where and are the radial and circumferential lengths of the magnetic resistance unit respectively, and are the circumferential and radial cross – sectional areas of the magnetic resistance unit, and are the outer and inner diameters of the magnetic resistance unit, and is the axial length of the magnetic resistance unit.

3.3.3 Equivalent Magnetic Network Equation

To accurately describe the calculation process of the magnetic flux at the nodes of the magnetic resistance unit, an inflow – node magnetic flux model is established, as shown in Figure 5. According to Kirchhoff’s magnetic circuit law, the sum of the magnetic fluxes flowing into a node is equal to the sum of the magnetic fluxes flowing out of the node. The flux balance equation.

where the calculation formulas for the magnetic fluxes flowing into adjacent nodes are:

Substituting these formulas into the flux balance equation, a non – linear magnetic network equation system is obtained.

where is the vector of magnetic potential at each node, is the coefficient matrix related to magnetic conductance, and is the vector related to magnetic potential sources.

3.4.3 Calculation of Loss

Assuming that the magnetic gear is composed of multiple laminated layers along the axial direction, the eddy – current loss is calculated using the thin – sheet model. The calculation formula.

where is the electrical conductivity of the magnetic resistance unit material, is the corresponding frequency, is the thickness of the magnetic resistance unit material, is the area of the magnetic resistance unit, and is the instantaneous value of the magnetic flux density at the sampling time point. If the influence of the number of axial layers on the eddy – current loss is considered, a correction coefficient needs to be multiplied at the end.

4. Case Study Analysis

4.1 Comparison between the Finite Element Method and the Magnetic Network Method

4.1.1 Radial Magnetic Flux Density of the Sinusoidal Magnetic Modulation Ring

The radial magnetic flux density distributions in the inner and outer air – gaps of the magnetic gear with a sinusoidal magnetic modulation ring, calculated by the magnetic network method and the finite – element method, are shown in Figure 7. The Fourier decomposition results are presented in Figure 8. The amplitude of the 1st harmonic and the 28th harmonic, which play crucial roles, are listed in Table 2. It can be observed that the curves of the radial magnetic flux density in the inner and outer air – gaps calculated by the magnetic network method are generally close to those of the finite – element method, but there is a slight deviation at the junction of the permanent magnet ends. The relative errors of the 1st harmonic amplitude in the outer air – gap and the 28th harmonic amplitude in the inner air – gap are 7.5% and 19.8% respectively, which meet the requirements of engineering design estimation.

| Harmonic Number | Magnetic Network Method (T) | Finite Element Method (T) | Relative Error |

|---|---|---|---|

| 1st harmonic (Inner Air – Gap) | 0.439 | 0.387 | 13.3% |

| 28th harmonic (Inner Air – Gap) | 0.438 | 0.546 | 19.8% |

| 1st harmonic (Outer Air – Gap) | 0.393 | 0.365 | 7.5% |

| 28th harmonic (Outer Air – Gap) | 0.113 | 0.031 | 264% |

4.1.2 Tangential Magnetic Flux Density of the Sinusoidal Magnetic Modulation Ring

The tangential magnetic flux density distributions in the inner and outer air – gaps of the magnetic gear with a sinusoidal magnetic modulation ring are shown in Figure 9, and their Fourier decomposition results are in Figure 10. Table 3 lists the magnetic flux density amplitudes of the 1st and 28th harmonics. The tangential magnetic flux density curves calculated by the magnetic network method are generally flat and in good agreement with those of the finite – element method. However, at the permanent magnet ends, the results of the magnetic network method are slightly smaller due to the relatively coarse local grid division. The relative errors of the 1st harmonic amplitude in the inner air – gap and the 28th harmonic amplitude in the outer air – gap are both less than 7%, while the relative errors of the 28th harmonic amplitude in the inner air – gap and the 1st harmonic amplitude in the outer air – gap are relatively large, being 51.9% and 28.9% respectively.

| Harmonic Number | Magnetic Network Method (T) | Finite Element Method (T) | Relative Error |

|---|---|---|---|

| 1st harmonic (Inner Air – Gap) | 0.035 | 0.038 | 6.3% |

| 28th harmonic (Inner Air – Gap) | 0.163 | 0.0339 | 51.9% |

| 1st harmonic (Outer Air – Gap) | 0.037 | 0.052 | 28.9% |

| 28th harmonic (Outer Air – Gap) | 0.030 | 0.029 | 3.7% |