The basic input involved in the dynamic equation of bevel gear transmission system. The time-varying meshing stiffness of bevel gear is shown in the calculation results. According to the initial conditions given by the formula, the dynamic response simulation results of transmission shaft, driving bevel gear, driven bevel gear and transmission rod can be obtained.

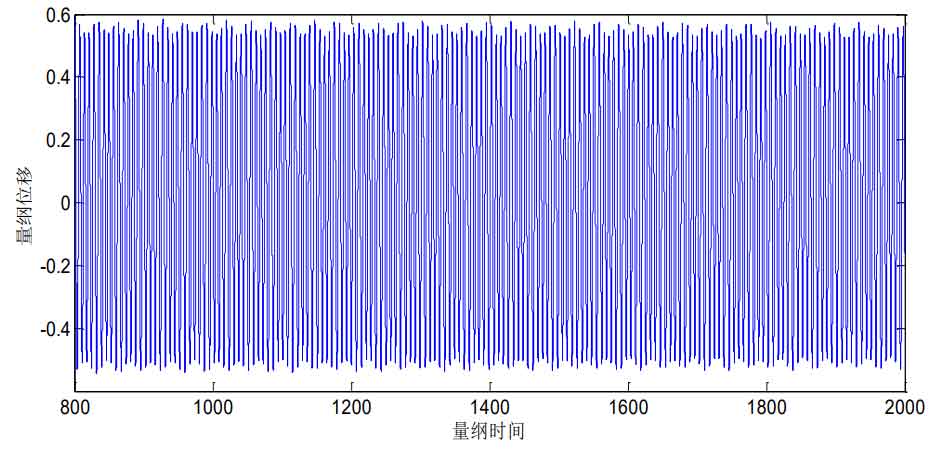

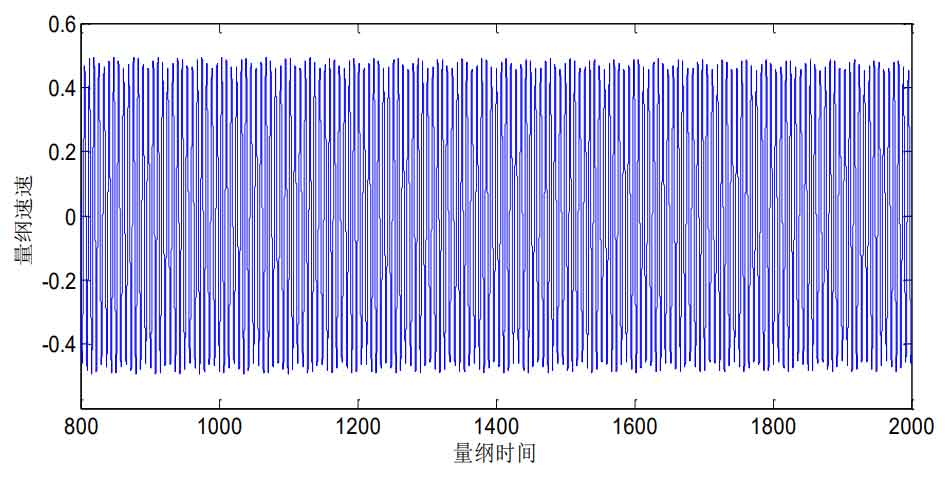

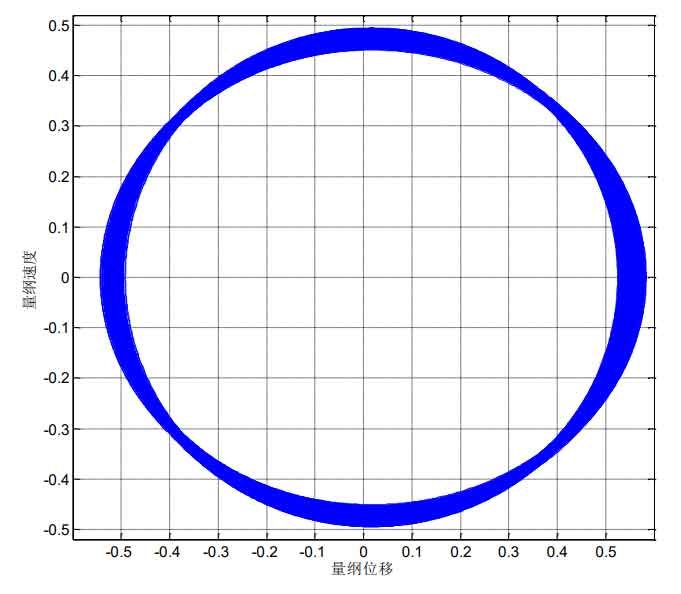

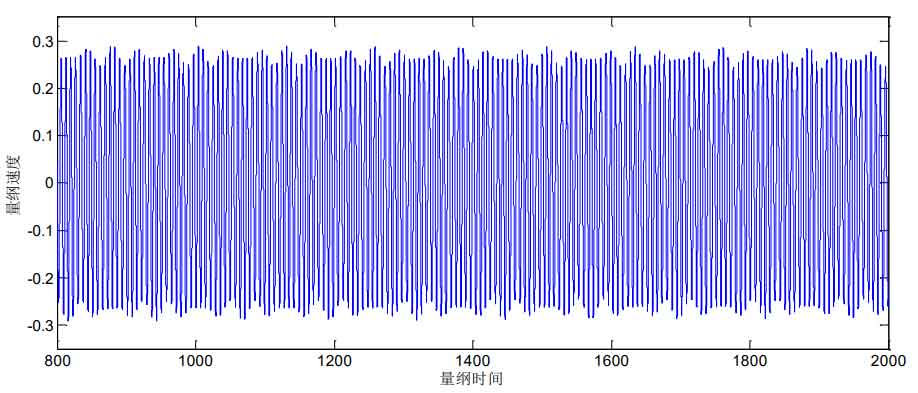

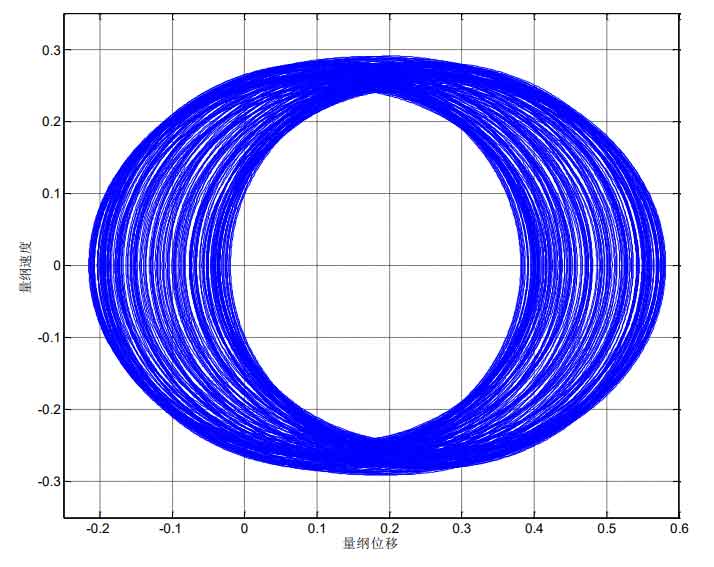

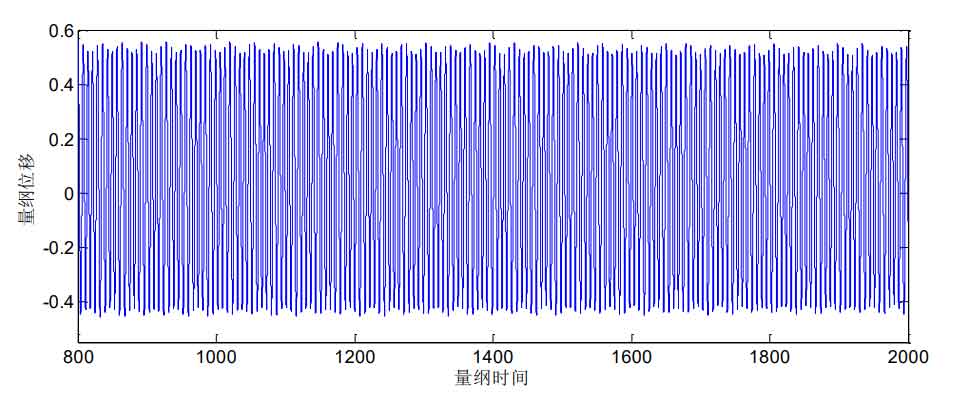

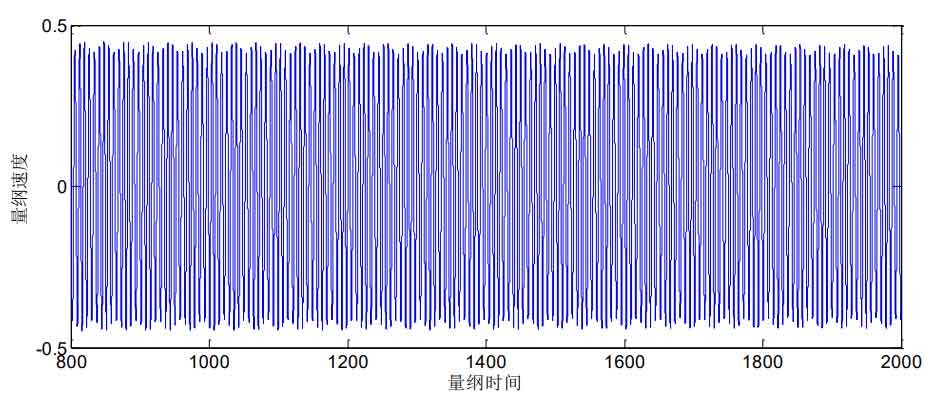

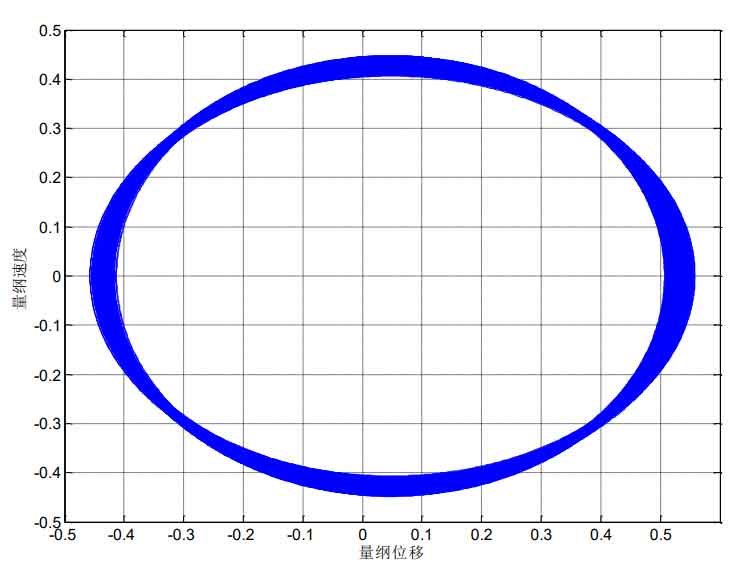

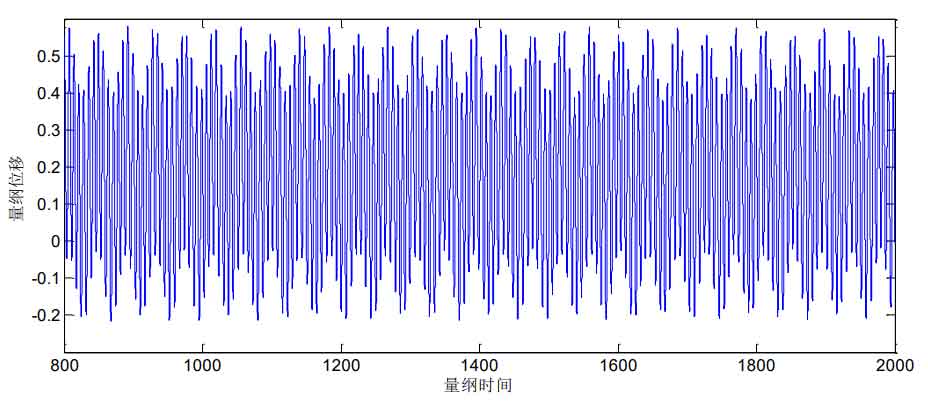

Under the working state of this type of aero-engine core engine, the engine high-pressure rotor speed is 12419r / min and the transmission power is 85KW. The vibration response of the engine central bevel gear transmission system under this state is simulated and analyzed. The corresponding time history diagram and phase plan are shown in Figures 1 to 9.

From the time history diagram of dimensional displacement of each component, it can be seen that the response of the system is an approximate periodic motion and is composed of multiple periodic motions. It can be seen from the phase plane that the motion trajectory on the phase plane is a curve band with a certain width, so the response of the system is a quasi periodic motion.

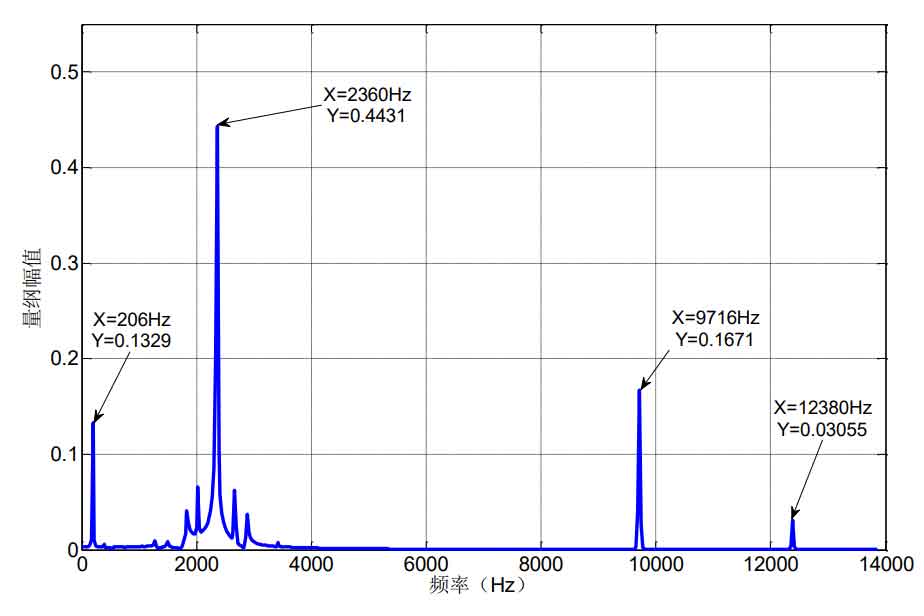

The spectrum of system response can be obtained by fast Fourier transform (FFT) of the response value of the fault bevel gear obtained by simulation. As shown in Figure 10:

From the spectrum diagram of fault bevel gear, it can be seen that the fault bevel gear system produces multi frequency response. There are four response frequencies with large amplitude, namely 206hz, 2360hz, 9716hz and 12380hz. The working speed of the core machine is 12419r / min, the corresponding rotation frequency is 207hz, and the number of teeth of the driving bevel gear is 47. It can be concluded that the meshing frequency of the central transmission bevel gear is 9728hz. Therefore, it can be seen that 206hz is the fundamental frequency and 9716hz is the meshing frequency of the central transmission bevel gear.

Combined with the analysis results of the natural characteristics of the fault bevel gear, it is found that the first-order and second-order natural frequencies of the driven bevel gear with two pitch diameters are 2456hz and 12464hz respectively, which are consistent with the frequencies of 2360hz and 12380hz calculated by simulation. There are great risks. Therefore, at the beginning of the design of the bevel gear, the resonance frequency of the two pitch diameter of the driven bevel gear should be adjusted off.