Stiffness is a characteristic value to measure the resistance of straight bevel gear blank to deformation during tooth cutting. The greater the stiffness of straight bevel gear blank, the less likely it is to deform. In material mechanics, the stiffness is usually expressed by the product of the elastic modulus of the material and its section moment of inertia.

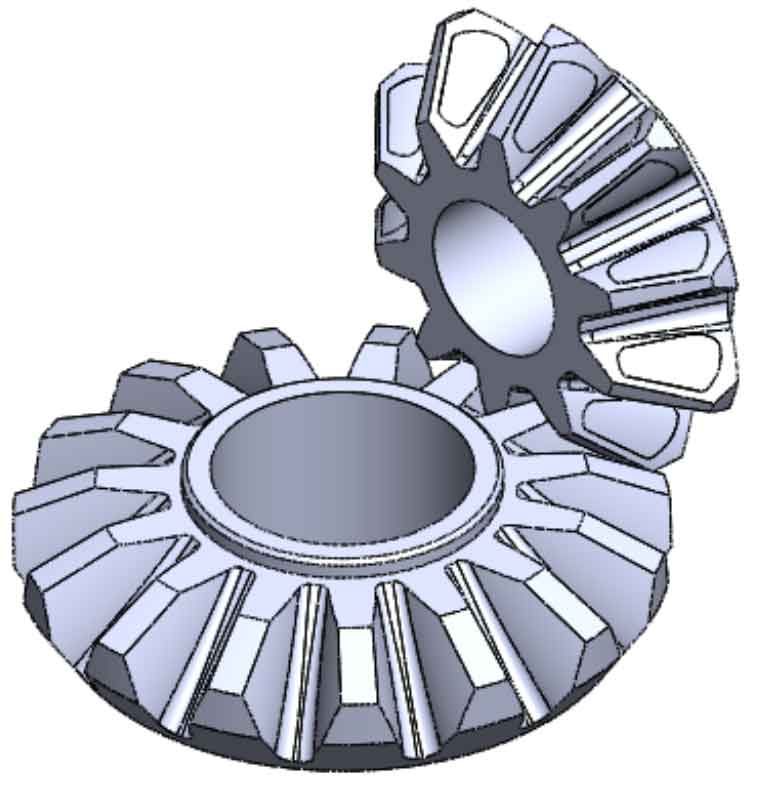

The structure of super large straight bevel gear blank is annular. In actual production, in order to facilitate gear cutting and transportation, it is usually divided into several split bodies, and then the straight bevel gear split blank is assembled to form the whole annular blank. The size of the straight bevel gear blank is large and the curvature is small. In order to facilitate the analysis, the studied split blank is approximately calculated as a beam structure. Therefore, the stiffness calculation formula of the straight bevel gear blank is EI / L, where e is the elastic modulus, I is the moment of inertia of the straight bevel gear blank section to the neutral axis, l is the length of the split blank, and the unit of stiffness is n / m.

The main deformation mode of straight bevel gear is bending deformation, which is determined by the structural characteristics of the slender shape of the straight bevel gear blank. Therefore, the stiffness mentioned is the bending stiffness of the straight bevel gear blank. In the process of gear cutting, the section shape of the straight bevel gear blank is constantly changing. From the length direction of the straight bevel gear blank, the section shape of the straight bevel gear blank in processing is rectangular and the height of the section changes in step. At this time, the traditional stiffness formula cannot be used to calculate the stiffness of the straight bevel gear blank. After consulting the data and analysis, it is proposed to use the method of equivalent stiffness.