(1) Control of noise caused by flow pulsation. Through the above analysis of the causes of noise, we can see that the pulsation rate of flow pulse should be reduced as much as possible. When selecting gear pump, the appropriate number of gear teeth should be selected according to the demand to control the noise caused by flow pulsation.

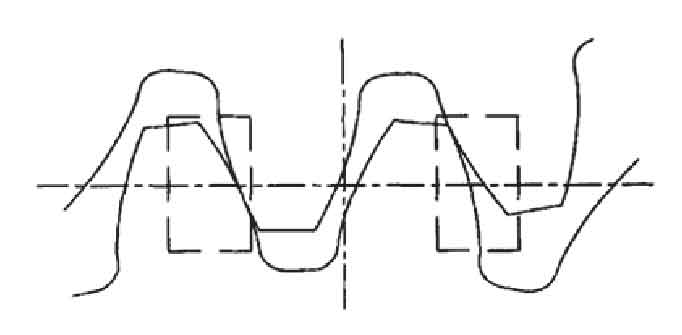

(2) Control of trapped oil noise. In order to control the noise caused by trapped oil, the unloading slot is often opened. The open unloading slot is divided into symmetric unloading slot and asymmetric unloading slot, as shown in Fig. 1 and 2. No matter what kind of slotting method, it can solve the oil trapping phenomenon of internal gear pump to a certain extent. The two methods have their own advantages and disadvantages. As far as the symmetrical unloading groove is concerned, the advantage is that it is easy to process, but the disadvantage is that it can not solve the noise problem at higher speed. The asymmetric unloading groove has an asymmetric structure, so it can greatly reduce the impact of medium oil. Its disadvantage is that it increases the difficulty of processing.

(3) Cavitation and cavitation noise control. It can be seen from the above cause analysis that in order to reduce the noise caused by cavitation and cavitation, the air entering the hydraulic oil in the pump chamber should be strictly controlled. At the same time, measures should be taken to reduce the oil suction resistance of gear pump. The oil suction resistance value should be controlled below 1 / 4 of the saturated vapor pressure value proposed by the manufacturer of hydraulic pump. Only in this way can the noise be effectively reduced.

(4) The noise control of gear running. In order to reduce the noise caused by gear operation, the shape of the gear can be processed to ensure that the meshing impact between the front and rear teeth can be reduced when the pump is running, so as to ensure the smooth transmission of the system, so as to achieve the purpose of reducing noise. Recently, it is found that the double modulus asymmetric involute circular arc profile gear can effectively improve the running stability of the unit, reduce the vibration of the unit, and thus reduce the noise.

(5) Control of mechanical noise. In view of the causes, the following measures should be taken to reduce the noise caused by mechanical factors, strictly implement the production specifications, implement the material approval system, improve the stiffness of parts, and select qualified and appropriate bearings, so as to avoid the damage of unit parts caused by high pressure impact. When designing the thickness of the casing, the high and low pressure oil pressure of the gear should be taken into account, so as to prevent the thickness of the casing from causing the gear to gradually lean to the low pressure side during operation, so as to control the mechanical noise and protect the unit.