Tooth contact fatigue failure and tooth root bending fatigue failure are one of the most common failure forms of bevel gear. They are very destructive to bevel gear transmission, and even lead to the instantaneous damage of the whole transmission system. The tooth contact fatigue strength and tooth root bending fatigue strength are taken as the reliability evaluation indexes of bevel gear transmission.

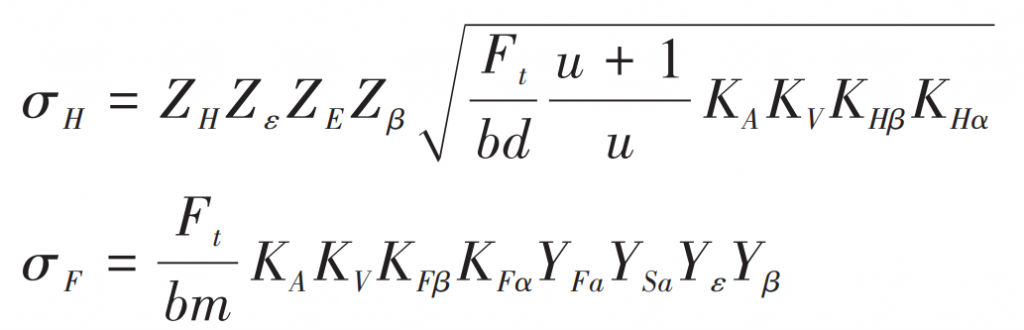

The DSI planetary gear train tooth surface contact stress σ H and root bending stress σ The calculation formulas of F are:

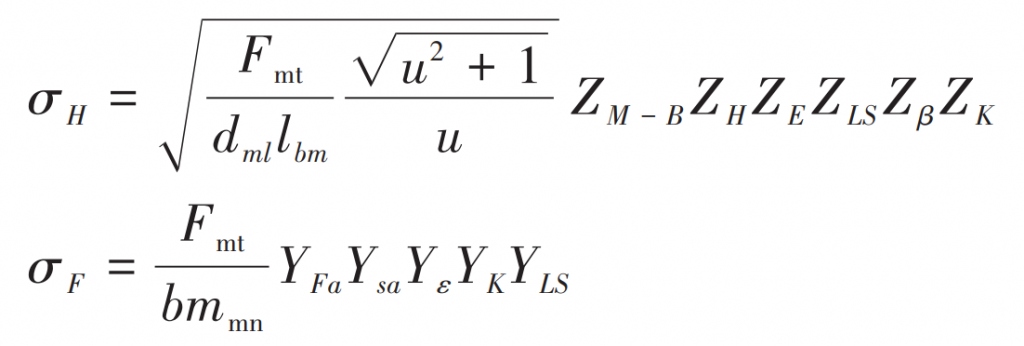

The calculation formulas of bevel gear tooth surface contact stress and tooth root bending stress are as follows:

Refer to GB / T 3480-1997 and GB / T 10062-2003 for specific parameter selection.

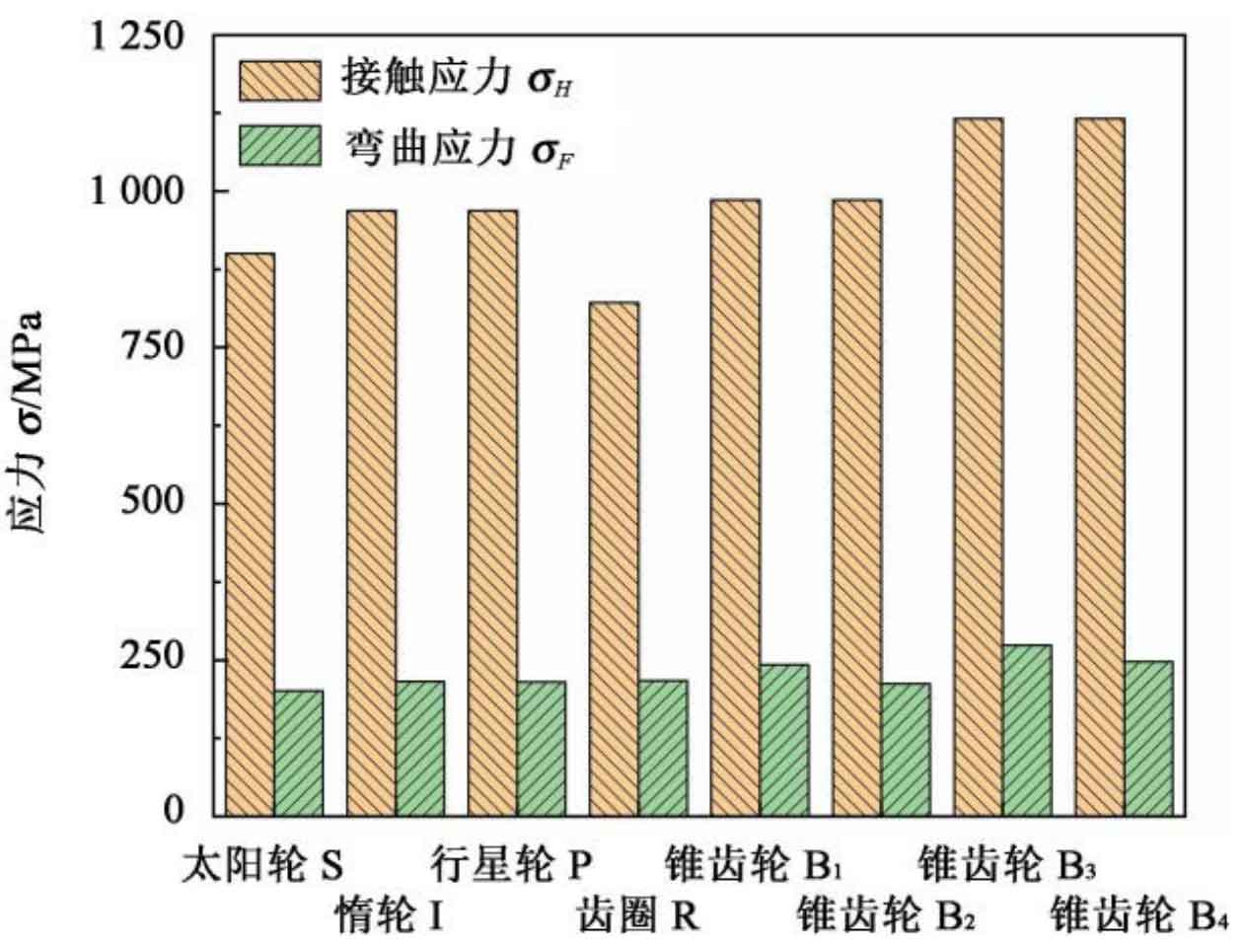

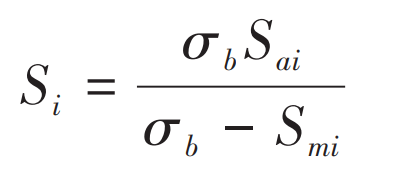

The calculation result is the maximum value of tooth surface contact stress and tooth root bending stress, which is the peak value of stress in the meshing process of bevel gear. The bevel gear is subjected to pulsating cyclic stress during operation, and the stress increases from 0 to the peak value and then decreases to 0. In order to effectively use the time history of tooth surface contact stress and tooth root bending stress to predict the contact and bending fatigue reliability of bevel gear, it is necessary to convert the pulsating cyclic stress of bevel gear into symmetrical cyclic stress. The Goodman formula is used for stress conversion:

Where, Si is the equivalent symmetrical cyclic stress; σ B is the tensile strength limit, taken as 1600 MPa; Sai is the ith stress amplitude; SMI is the ith mean stress. According to the load spectrum obtained in Fig. 3, the symmetrical cyclic stress of bevel gear in the transmission system under different flight states can be obtained. The flying vehicle mainly has five typical mission profiles. Taking the high-altitude mission profile as an example, its equivalent cyclic stress is shown in the figure, which will be used as the stress input variable of the stress strength interference theory.