The application of manganese phosphate conversion coating technology in improving the surface strength of transmission parts first appeared in improving the fatigue life of bearing rollers. The manganese phosphate conversion coating obtained after phosphating treatment can effectively reduce the friction coefficient of the friction pair surface and has good anti seizing or scuffing performance.

In the research and practice of high-strength gears, ZHY gear has applied the technology of manganese phosphate conversion coating to the gears of auto transmission for the first time. Chongqing University and ZHY gear 20Cr gear surface prepared super micro manganese phosphate conversion coating, studied the relationship between the phosphating grain size and the oil storage characteristics of the surface pores of the coating, the results showed that the super micro manganese phosphate conversion coating on the steel surface had obvious friction reducing and wear-resisting effects under the condition of oil immersion lubrication.

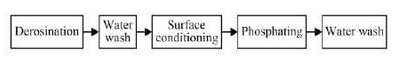

Wang et al. Studied the effect of post-treatment and lubrication of phosphating film on its tribological properties. The manufacturing process of manganese phosphate conversion coating mainly includes pretreatment of gear surface with degreaser in degreasing tank at 70-95 ℃, water cleaning, and surface adjustment at 40-80 ℃. The temperature of phosphating treatment is 80-100 ℃, the acid ratio is controlled at 5.6-6.2, and the processing time is 10-15 min. The process flow is shown in Figure 20, and the formation of coating is realized by the following chemical reactions:

Mn(H2Mn(H2PO4)2⇁↼MnHPO4 + H3PO4

Fe(H2PO4)2⇁↼ FeHPO4 + H3PO4

3(Mn,Fe)(H2PO4)2⇁↼(Mn,Fe)3(PO4)2 + 4H3PO4

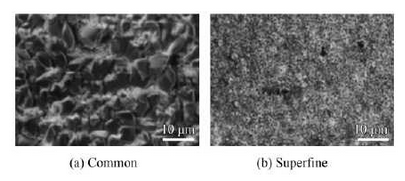

By controlling the process parameters of the conversion coating of manganese phosphate to affect the density and grain size of the coating, the ultra-fine conversion coating of manganese phosphate can be obtained. After treatment, a soft layer of 3-5 μ m is produced on the tooth surface, and the density of the coating is about 2.2g/m2.

After the treatment of manganese phosphate conversion coating, the soft layer of several microns is produced on the surface of gear, which fills up most of the concave and convex cutting ripples on the surface of gear, reduces the local maximum meshing contact stress on the surface of gear and the friction coefficient on the metal surface, and improves the oil film condition and lubrication condition when the gear is meshed.

After treatment, the surface morphology is observed by SEM as shown in the figure. The selection of ordinary manganese phosphate coating treatment and ultra-fine manganese phosphate coating treatment needs to be determined by combining gear processing technology and actual working conditions.

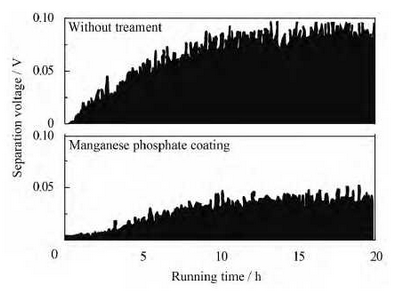

The figure shows the formation of oil film on the cylindrical roller. The formation of oil film on the cylindrical roller is observed by the separation voltage resistance measurement method. The separation voltage of the cylindrical roller after the treatment of manganese phosphate coating starts to rise after 30 min, and the formation energy of oil film is obviously better than that of the untreated cylindrical roller.

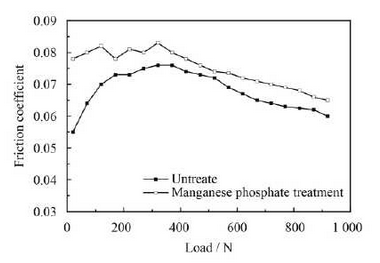

The tribological properties of the coating under certain working conditions were evaluated by friction and wear tests. As shown in the figure, according to the working load and lubrication conditions of the gear, the friction and wear test of the manganese phosphate coating is carried out. The ultra-fine manganese phosphate conversion coating has good sustained friction and wear resistance characteristics under low load and high load conditions.

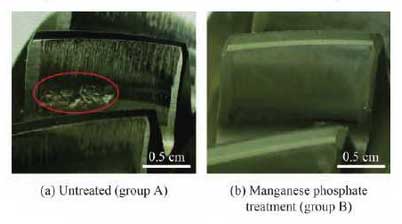

The figure shows the surface morphology pitting of two sets of at gears provided by Japan’s jatco automatic transmission company to Volkswagen in accordance with the durability test requirements under the same test conditions. The two gear pairs were processed by the same process. Group B gear pair was treated with manganese phosphate conversion coating, while group a gear pair was not treated.

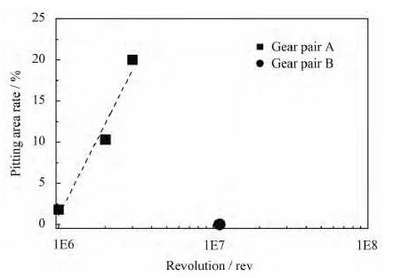

As shown in the figure, when the maximum pressure Pmax of the contact point of the tooth surface is 2000 MPa and the maximum sliding speed of the tooth root is 7.8 M / s, the horizontal axis represents the number of engagement cycles, and the vertical axis shows the pitting area rate under each cycle. Group a gear was damaged by pitting under 3 × 106 Rev cycle, while group B gear was not damaged after 1.1 × 107 Rev cycle. The results show that the anti pitting fatigue life of transmission gears is increased by 3 to 4 times by the coating.