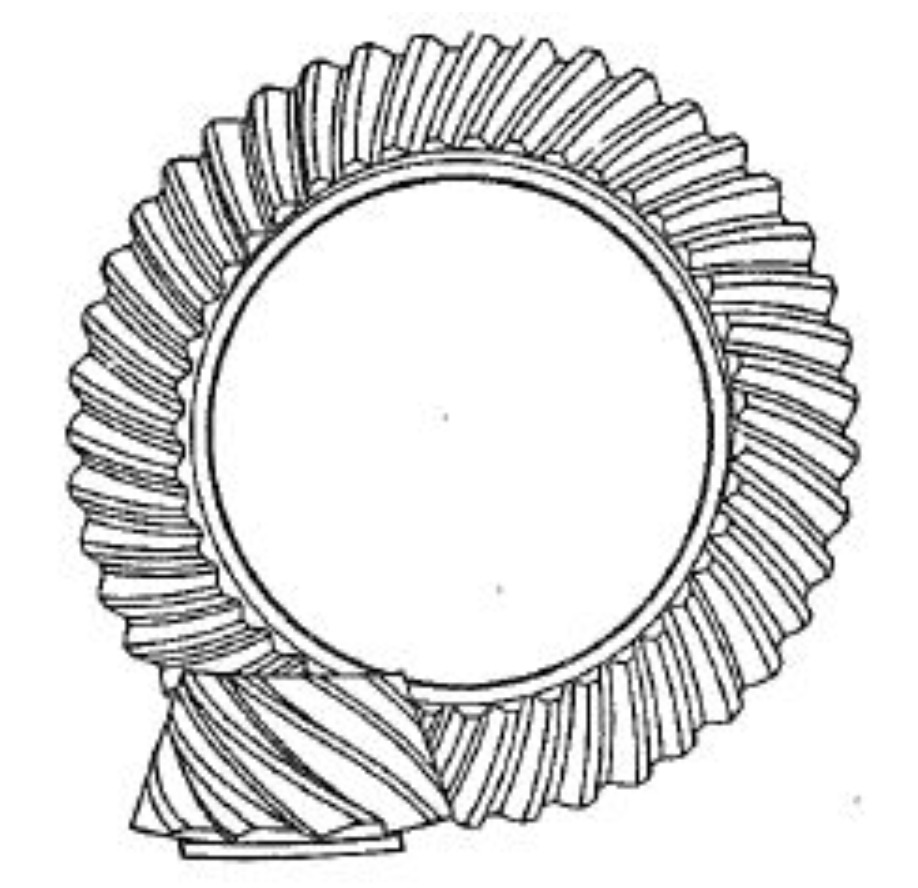

This study addresses the challenges in controlling meshing quality for high reduction hypoid gears (HRH) through advanced surface synthesis and modification techniques. A comprehensive mathematical framework is developed to optimize tooth contact patterns and dynamic performance.

1. Spatial Meshing Equation and Coordinate Transformation

The general meshing equation for crossed-axis gear transmission is established as:

$$f(u, v, \phi) = \mathbf{n} \cdot \mathbf{v}^{(12)} = 0$$

Where the velocity components in orthogonal directions are expressed as:

$$

\begin{cases}

U = n_x(E + z_2\cos\gamma) – n_z(y_2 – G) \\

V = n_z(x_2 – E) – n_x(z_2\sin\gamma + G) \\

W = n_y(x_2 – \frac{m_{21}}{\sin\gamma}n_zE)

\end{cases}

$$

2. Crowned Tool Surface Modification

The modified cutter profile with parabolic correction is defined by:

$$

\begin{cases}

w = 0.5a(u – u_0)^2 \\

\alpha_2(u) = \arctan(w’) + \alpha_0

\end{cases}

$$

Key tool modification parameters are summarized in Table 1.

| Parameter | Concave | Convex | Gear |

|---|---|---|---|

| Cutter radius (mm) | 77.725 | 72.644 | 37.3/38.9 |

| Pressure angle (°) | 20.0 | 28.0 | 21.0 |

| Radial setting (mm) | 52.086 | 51.678 | 53.151 |

3. Ease-off Topology Control

The ease-off gradient ellipse is formulated as:

$$

\frac{x^2}{a^2} + \frac{y^2}{b^2} = \frac{\delta^2}{4}

$$

With curvature correction parameters:

$$

\begin{cases}

k_a = \frac{8\delta}{a^2} \\

k_b = \frac{8\delta}{b^2}

\end{cases}

$$

4. Machine Setting Optimization

The numerical solution for machine settings is obtained through constrained optimization:

$$

\min \sum_{i=1}^{15} [\mathbf{r}_s^{(i)} – \mathbf{r}_1^{(i)}]^2 + [\mathbf{n}_s – \mathbf{n}_1]^2

$$

Key optimized parameters for hypoid gear generation include:

- Machine root angle: 10.991°

- Vertical offset: 39.884 mm

- Cradle ratio: 20.015

5. Contact Pattern Simulation

The ease-off topography (Figure 1) demonstrates effective contact pattern control with maximum deviation of 196 μm. Transmission error analysis reveals:

$$

\Delta\phi = \frac{1}{2\pi} \int_0^T \left(\frac{\omega_1}{\omega_2} – \frac{z_2}{z_1}\right) dt

$$

6. Dynamic Performance Validation

Vibration spectra show dominant meshing frequency components:

$$

A(f) = \sum_{n=1}^\infty C_n \delta(f – nf_m)

$$

Where the meshing frequency for 3:60 hypoid gear pair at 1410 rpm is:

$$

f_m = \frac{1410}{60} \times 3 = 70.5 \text{ Hz}

$$

7. Conclusion

The proposed surface synthesis method enables precise control of hypoid gear tooth contact characteristics, achieving:

- Contact ellipse ratio 1:2.4

- Transmission error < 1 arcmin

- Vibration acceleration < 3.11 m/s²

This methodology provides an effective solution for high-reduction hypoid gear design and manufacturing, particularly suitable for applications requiring high power density and silent operation.